US baby formula manufacturer Abbott Nutrition says its production plant — closed for months due to contamination — has reopened, taking a step towards alleviating a nationwide shortage that has sent parents scrambling for supplies.

The February shutdown of the largest formula factory in the US led to supply problems that have forced some parents to seek formula from food banks, friends and doctors' offices.

Abbott said it would initially prioritise production of its EleCare specialty formulas for infants with severe food allergies and digestive problems who had few other options for nutrition.

The company said it would take about three weeks before new formula from the plant began getting to consumers.

"We will ramp production as quickly as we can while meeting all requirements," Abbott said in a statement.

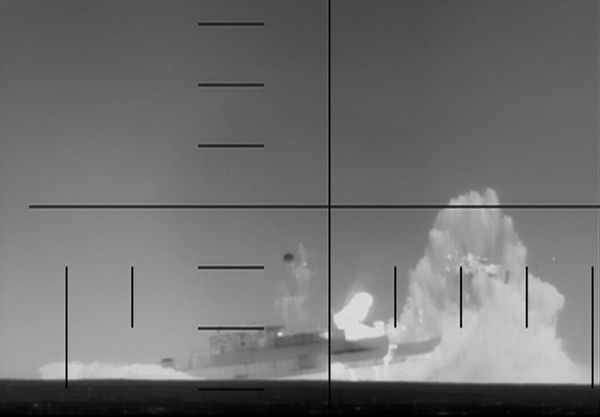

In response to the supply shortage, US President Joe Biden's administration has eased import rules for foreign manufacturers, flown in formula from Europe and invoked federal emergency rules to prioritise US production.

US Food and Drug Administration (FDA) commissioner Robert Califf recently said it could be about two months before formula supplies returned to normal levels in the country.

The FDA has waived many of its regulatory requirements to accept more formula from the United Kingdom, Australia and other nations.

The government ordered some 1.25 million cans of formula from Sydney-based manufacturer Bubs Australia to help alleviate shortages.

Shortage severely impacts babies with allergies, digestive issues

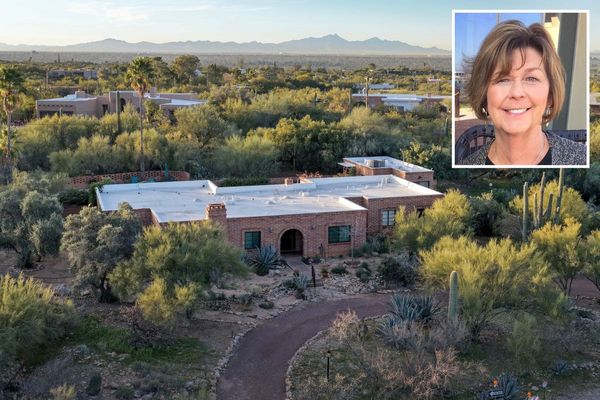

Abbott closed the factory in Sturgis, Michigan, in February after the FDA began investigating four bacterial infections among infants who consumed powdered formula from the plant.

Two of the babies died.

The company continues to state that its products have not been directly linked to the infections, which involved different bacterial strains.

FDA inspectors eventually uncovered a host of violations at the plant, including bacterial contamination, a leaky roof, lax safety protocols and a lack of adequate handwashing among staff.

The FDA has faced intense scrutiny for taking months to close the plant and then negotiate its reopening.

Agency leaders recently told US Congress they had to enter a legally binding agreement with Abbott to ensure all the problems were fixed.

Abbott's February recall of several leading brands, including Similac, squeezed supplies that had already been strained by supply chain disruptions and stockpiling during COVID-19 shutdowns.

Roughly 73 per cent of baby products were out of stock in the US as of May 22, according to data firm Datasembly.

The shortage has been most dire for children with allergies, digestive problems and metabolic disorders, who rely on specialty formulas.

The Abbott factory is the only source of many of those products, providing nutrition to about 5,000 babies, according to US officials.

Abbott is one of just four companies that produce about 90 per cent of formula in the US.

And according to government data from 2020, fewer than half of American babies were exclusively breastfed through their first three months.

The company's recalls and shutdown triggered a cascade of effects: Retailers have limited customer purchasing to conserve supplies, and parents have been told to switch brands to whatever formula is in stock.

US manufacturers, including Reckitt and Gerber, have also stepped up production, running plants 24/7 and sourcing more formula from alternate facilities.

ABC/wires