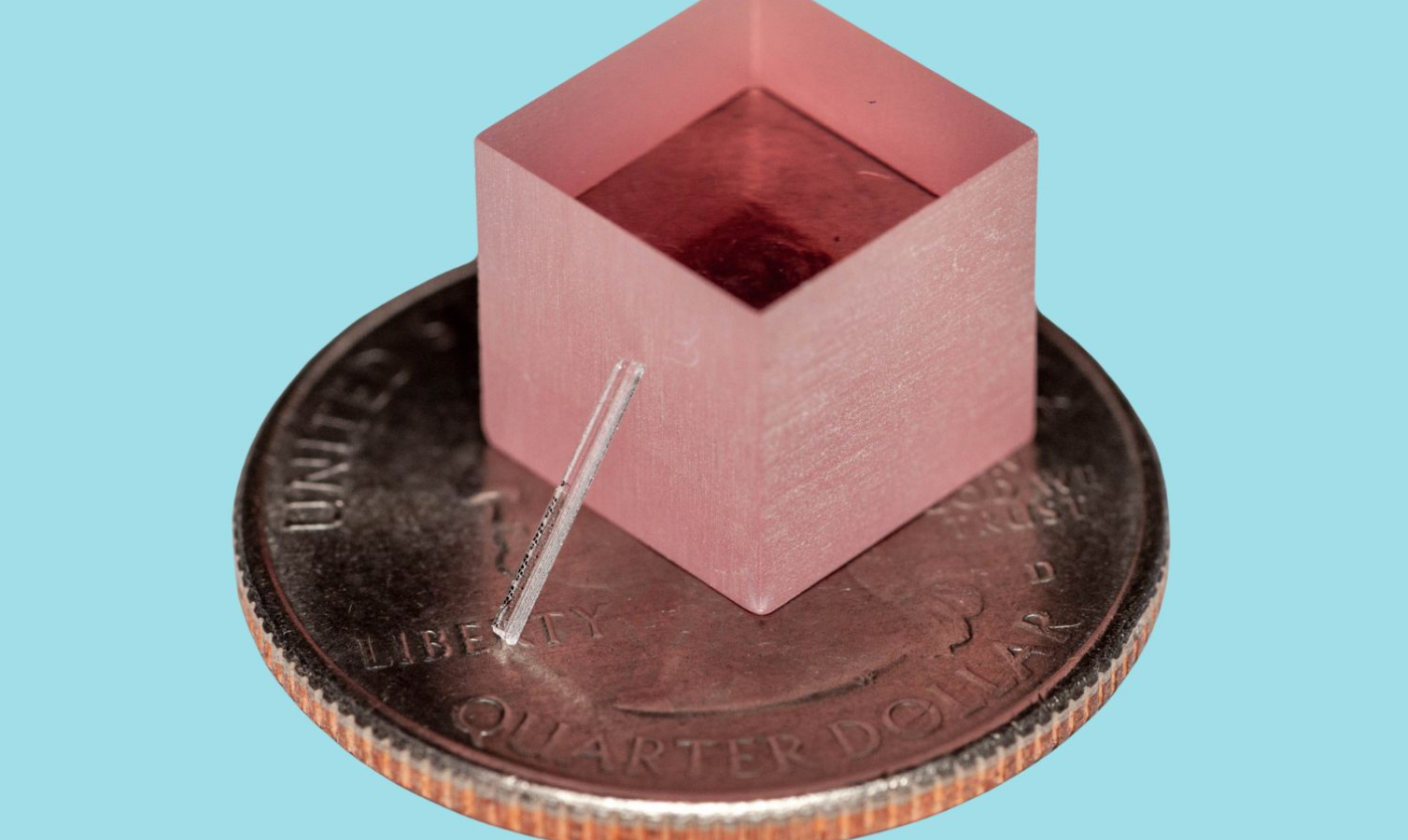

Stanford researchers have built a titanium-sapphire (Ti:Sa) lasers that are 10,000 times smaller than any previous similar device and fit them onto a chip.

Until now, such lasers have cost upwards of $100,000. But with a new approach, outlined June 26 in the journal Nature, scientists believe the cost could drop to $100 per laser.

They also claimed that thousands of lasers could be built onto one four-inch wafer in the future — and the cost per laser could become minimal. These small-scale lasers could be used in future quantum computers, in neuroscience and even in micro-level surgeries.

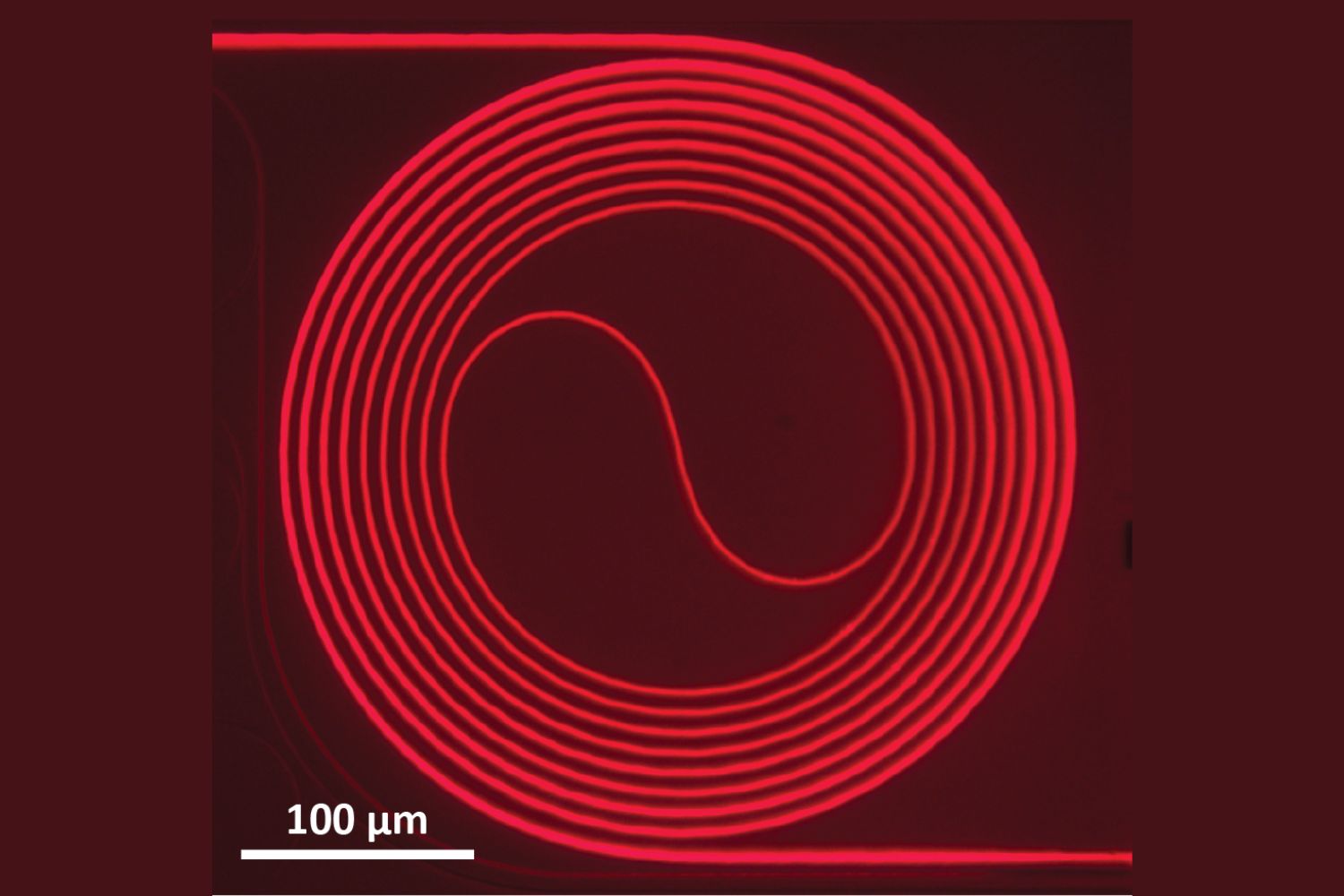

The experimental laser relies on two crucial processes. First, they ground a sapphire crystal down to a layer just a few hundred nanometers thick. They then fashioned a swirling vortex of tiny ridges, into which they shone a green laser pointer. With each rotation within that vortex, the laser’s intensity increased.

"One of the trickiest parts was the production of the platform," co-first author of the study Joshua Yang, a doctoral candidate at Stanford, told Live Science. "Sapphire is a very tough material. And when you grind it down, oftentimes, it doesn’t like it, it cracks, or it damages what you’re using to try to grind out."

Related: New invention transforms any smartphone or TV display into a holographic projector

Once this problem was solved, however, Yang described the process as "smooth sailing." But he was keen to emphasize that while the team was at the starting point they can already "bat with semiconductor laser technology that’s had over a decade to mature."

One reason the team is so optimistic is that its lasers can be tuned to different wavelengths; specifically, from 700 to 1,000 nanometers, or red to infrared.

This is crucial for atomic researchers, said Yang, citing solid-state qubits as one example. "These atomic systems require different energies [to make a transition from one state to another]," he said. "If you buy one laser that has a small gain bandwidth and the other transition is outside that bandwidth, then you have to get another laser to address that other system."

Yang and his colleagues have also created a company, Brightlight Photonics, to commercialize the technology.

"The first opportunity that we really do see is the academic research market," Yang said. "As researchers, we know this need for lasers. And we know that what we can provide is much better than what’s currently on the market."

While Yang wouldn’t be tied down to exact prices, he said it would depend on what functionality is built in but it will certainly be an order of magnitude less than current Ti:Sa lasers.

The miniature lasers could be used in quantum computers — helping to make them much smaller in the process. They could also revolutionize the field of optogenetics, Yang said, where scientists control neurons with light guided inside the brain; currently, they use chunky optical fiber technology. Finally, miniature Ti:Sa lasers can be used in laser surgery.

All this relies on Yang and his colleagues successfully further miniaturizing and mass-producing the technology so that hundreds, or even thousands, of lasers can fit on one four-inch wafer.

Yang is confident of success, however, saying that he believes the first "tunable laser" for academic users could go on sale within two years. He added: "The potential applications of these miniaturized lasers are vast and who knows where we’ll be five years from now?"