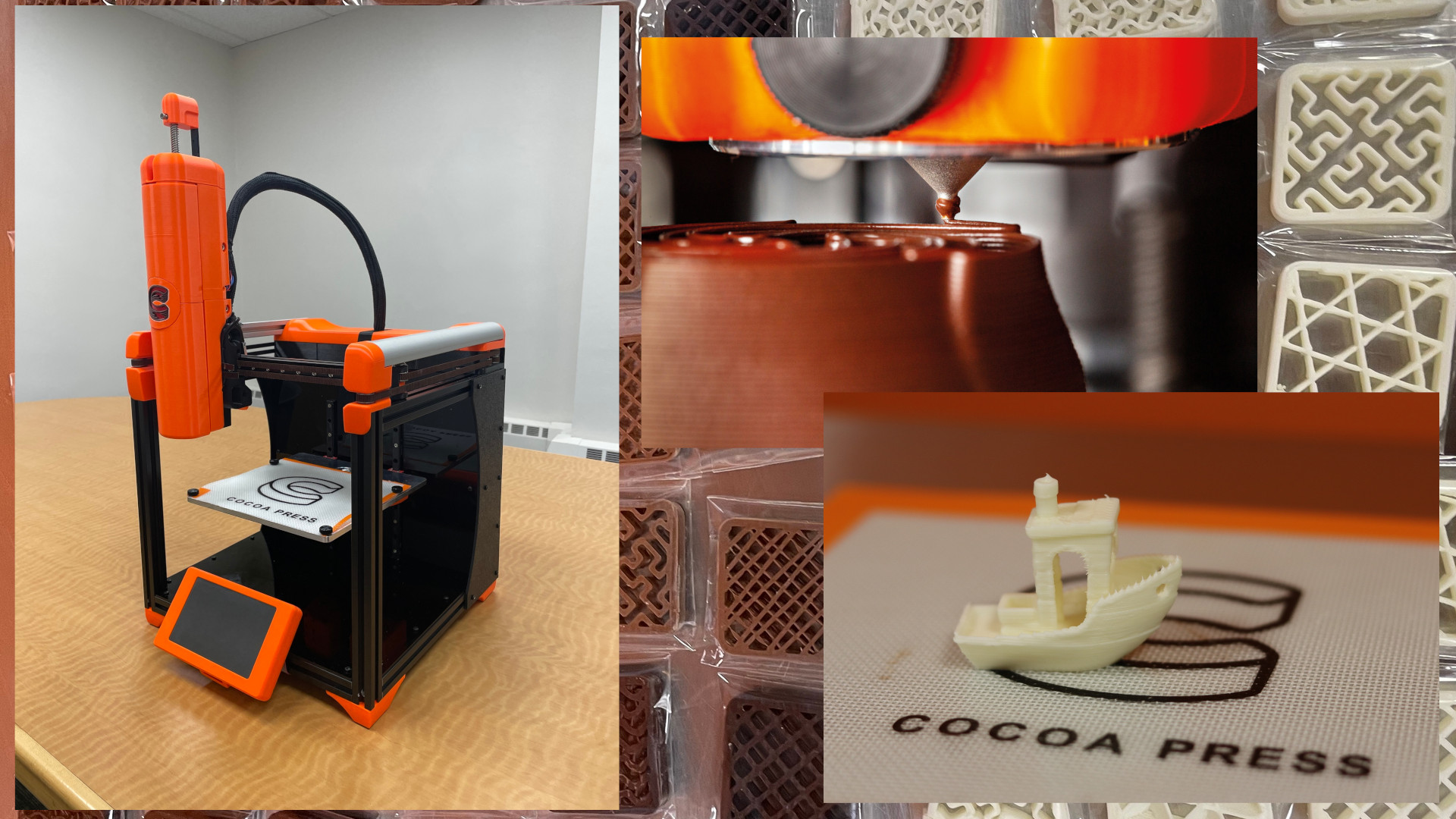

Typical 3D printers use either the best filaments, or resins to produce prints. But Ellie Rose Weinstein's Cocoa Press 3D printer uses chocolate to produce edible creations. The long-anticipated printer is now available for pre-order on Cocoa Press's website with a $100 deposit. The printer will cost $1,499 and come as a kit you need to assemble yourself when it ships this fall.

Weinstein talked about the printer at length when she joined us on a recent episode of the Tom's Hardware Pi Cast. You can see a video of our interview below.

Cocoa Press is an FDM (Fused Deposition Modeling) 3D printer which produces objects using layers of chocolate. The position and thickness of layers is controlled using G-Code, a programming language for CNC (Computer Numerical Control) used in computer-aided manufacturing.

The basic gist of the language is that it tells a tool / device to “go there, and do this”. Weinstein's Cocoa Press does exactly the same thing as many of the best 3D printers, but instead of extruding molten plastic, special chocolate recipes are used instead.

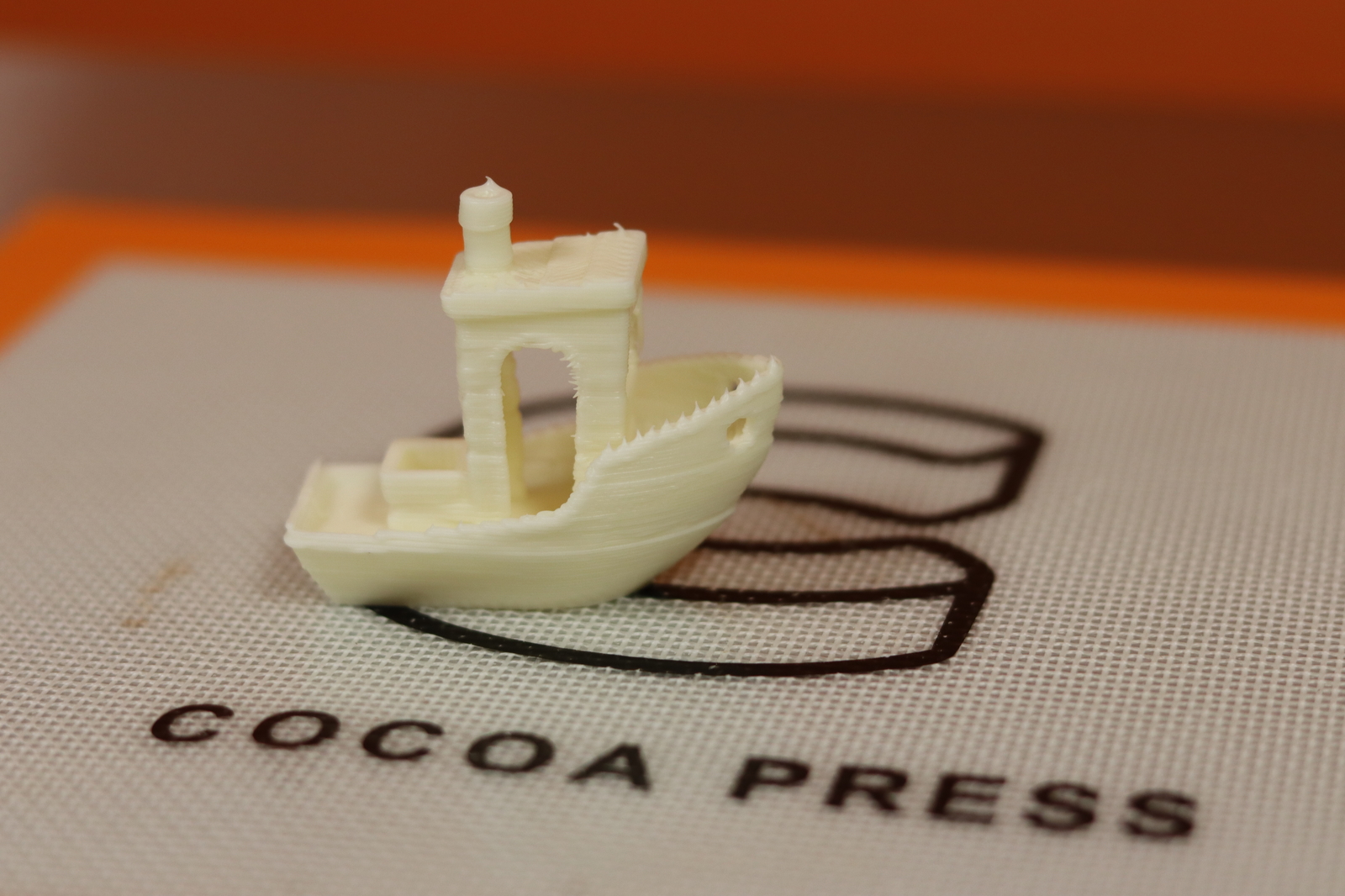

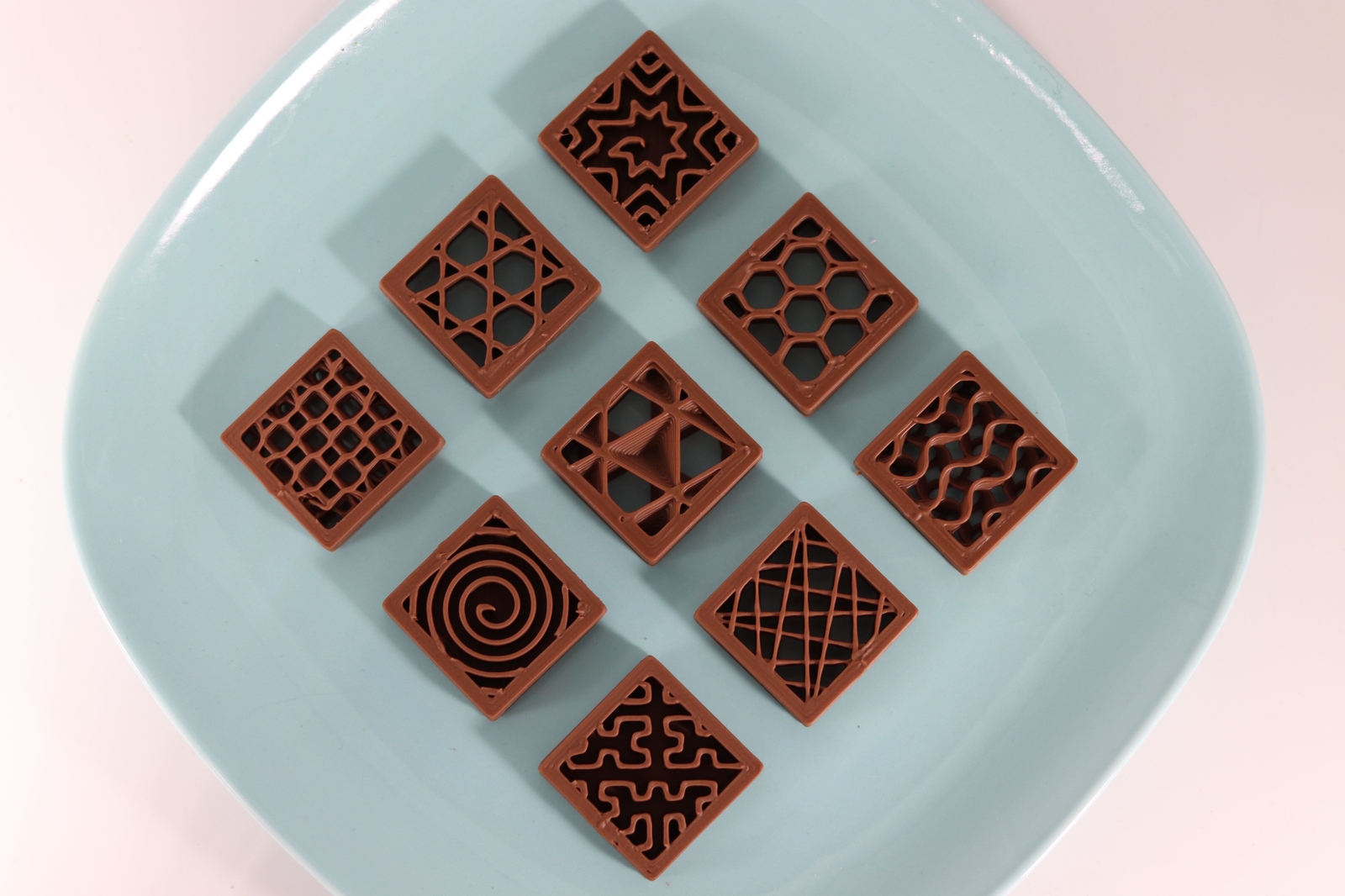

The recipes (for milk and dark chocolate) are formulated to work with the printer, but with some experimentation users can create their own chocolate, something which Weinstein is keen for users to do. The chocolate "filament" is delivered in 70g "chocolate cores" cylinders which contain no air bubbles. The cylinders are heated to just above body temperature and then extruded onto the build plate using 10 pounds of force. The chocolate then cools to form a layer.

FDM printers use a nozzle to extrude the heated material, and Cocoa Press is no different. Instead of a traditional 0.4mm nozzle, Cocoa Press uses a 0.8mm nozzle. This means it can lay down more material, faster. The dual heating system ensures that the nozzle receives a constant stream of chocolatey goodness.

Cocoa Press has a build volume of 140 x 150 x 150 mm, a small build volume which is comparable to Creality's Ender 2 Pro. But the build volume is more than enough for the 70g of chocolate. Larger builds, requiring more chocolate are being looked into, with a hope to release a means to reload chocolate during a print. Cocoa Press has a footprint of 365 x 315 x 700 mm, so it can easily fit in your working environment.

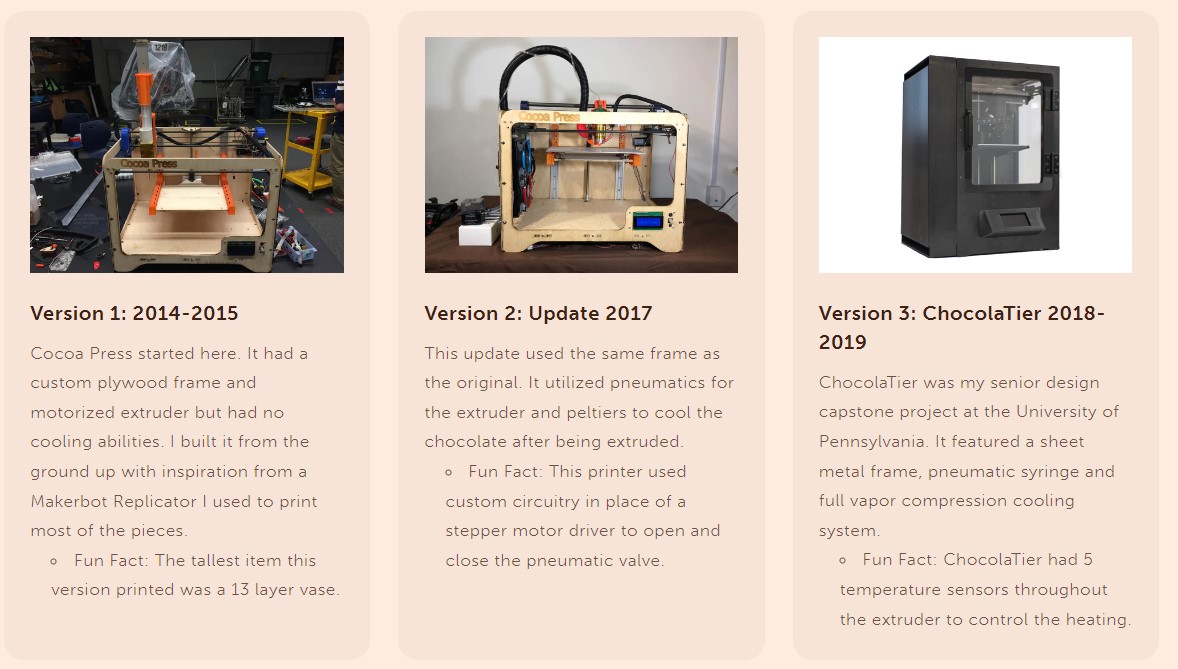

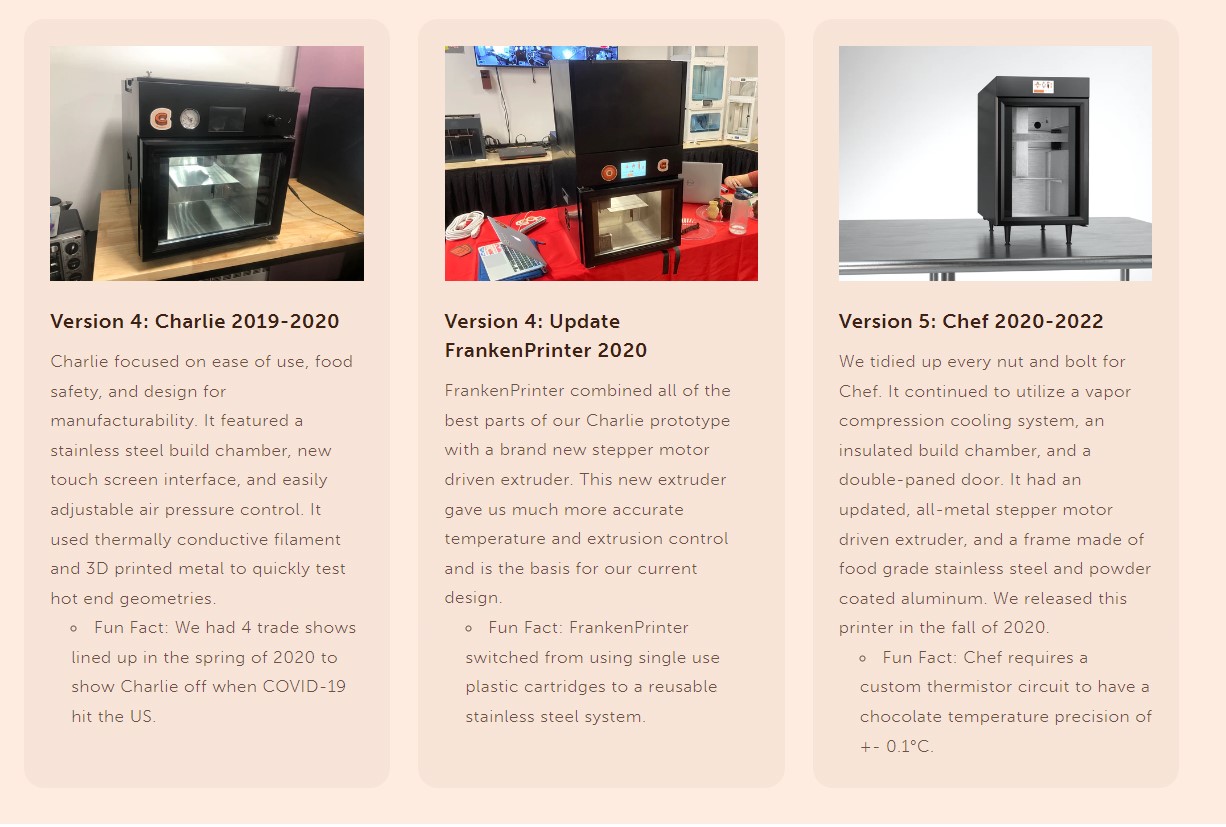

Creator Ellie rose Weinstein has been working on Cocoa Press since 2014, starting as a hobby, the project became a full time job in May 2019. Cocoa press has been through six iterations, initially taking inspiration from a Makerbot Replicator. Over time Cocoa Press has improved into what we see today. The current Cocoa Press can print in place mechanical gears, flexible models (for example a fish) and can use different infill patterns to produce various textures. Using Cocoa Press is as easy as loading chocolate into the printer, browse the designs on printables.com (or make your own), slice the designs using PrusaSlicer and then print.

Cocoa Press is available as a DIY kit for $1,499, or as a professional package which starts from $3,995. A $100 deposit is required to secure your printer, and DIY kits will ship in late 2023 and professional packages in early 2024. Cocoa Press claims that DIY kits will require 10 hours of build time and that users should have access to a 3D printer in order to print some of the parts. A 3D printed parts add-on (for those without a 3D printer) will be available to order in the fall.