According to a Bloomberg report, Amkor Technology, one of the world's largests outsourced semiconductor assembly and test (OSAT) providers, has inked a preliminary agreement with the U.S. government to receive funding for its new advanced chip packaging and test facility in Peoria, Arizona. The facility will cost $2 billion and will be located close to TSMC's upcoming Fab 21 complex in Arizona to support customers making chips there.

Amkor's new facility near Peoria, Arizona, its first domestic packaging site, will be the largest of its kind in the United States. The company has secured 55 acres of land for the campus, which will include over 500,000 square feet (46,451 square meters) of cleanroom space when fully built and equipped. To give a sense of scale, this cleanroom area will be more than twice the size of the cleanroom space at Amkor's advanced chip packaging facility in Vietnam.

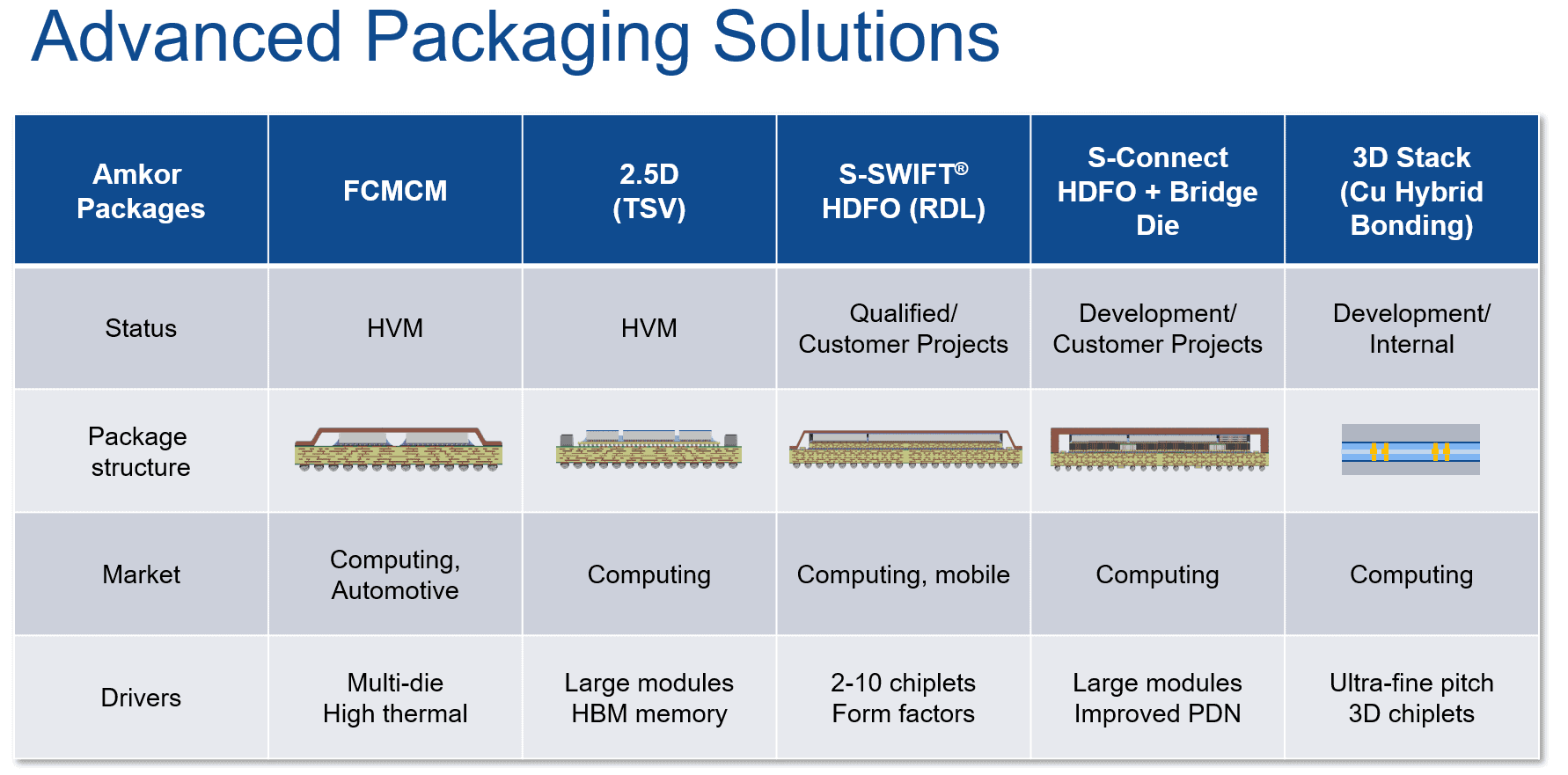

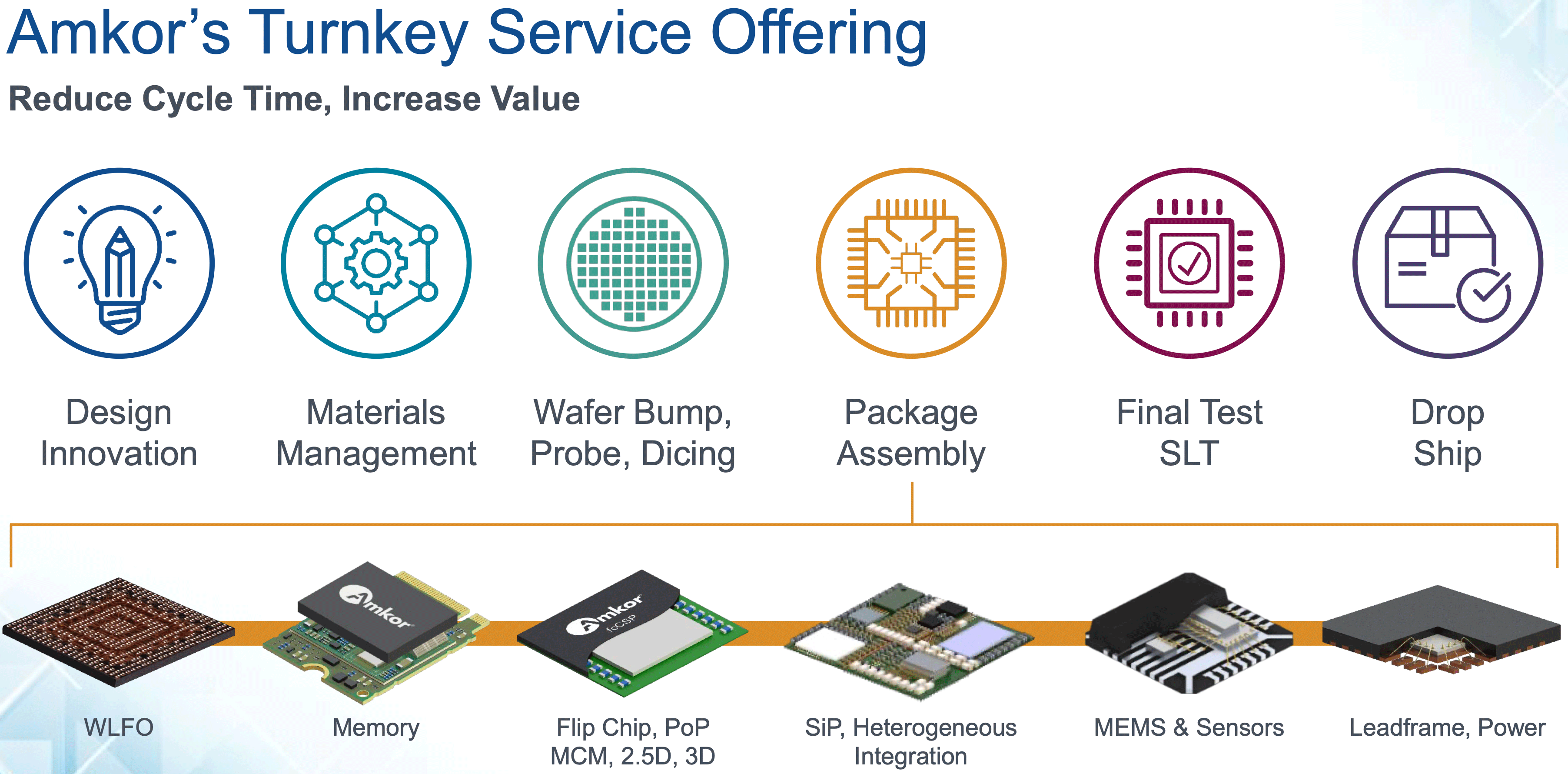

Amkor does not disclose capacity of the upcoming campus (probably because it depends on many factors) or which technologies it would support (though, these are aligned with Apple's requirements), but says that the new packaging plant will serve automotive, high-performance computing, and mobile applications, so it is reasonable to expect it to offer a wide range of traditional, 2.5D and 3D packaging technologies.

The initial phase of the Peoria, Arizona, facility is expected to be operational within three years, in 2027. The adjacence of the OSAT plant to Intel Foundry's and TSMC's fabs in Arizona enables chip designers that use the said contract chipmakers to package their chips in the state. Essentially, Amkor's facility enables a strong domestic semiconductor supply chain and positions Amkor as a key partner for fabless chip designers and foundries.

In fact, Amkor and TSMC have a close working relationship and collaborate to meet their mutual customer needs in Taiwan. This collaboration promises to ensure the seamless integration of technology across a global manufacturing network, so companies like Apple and Nvidia can produce and package the same chips both in Taiwan and the U.S. Meanwhile, given the timelines of TSMC's Fab 21 (phase 1 coming online in 2025) and Amkor Arizona (starting operations by 2027), the first chips that the OSAT house will package will be made on TSMC's N5, N5P, N4, N4P, and N4X production nodes.

Amkor worked extensively with Apple on the strategic vision and initial manufacturing capabilities for the Peoria facility, which will package and test chips manufactured at the nearby TSMC fab for Apple. Upon opening, Apple will be the facility's first and largest customer. Apple has publicly endorsed Amkor's Arizona packaging facility and said that it would use TSMC and Amkor services in Arizona to make and package its chips. Given the company's usual tight-lipped attitude, a commitment to TSMC and Amkor is a significant move, perhaps aimed to persuade the U.S. government to fund the projects.

This facility requires a $2 billion investment and will create around 2,000 jobs. The agreement with the U.S. Department of Commerce outlines potential funding, including up to $400 million in direct financial support and access to $200 million in loans under the CHIPS & Science Act. Additionally, Amkor plans to benefit from an Investment Tax Credit, covering up to 25% of its eligible capital expenditures.