Union leaders have told Tata Steel they must keep a blast furnace at Port Talbot steelworks open until 2032 or else risk the future of the company’s UK steelmaking, in a last-ditch attempt to avert job losses.

Tata Steel was this month on the verge of announcing the near-immediate closure of the two blast furnaces, with the expected loss of 3,000 jobs. However, it dramatically pulled the announcement at the last moment, giving the unions the chance to argue their case.

Two of the main unions representing workers, Community and GMB, are backing proposals drawn up by the consultancy Syndex and presented them to Tata Steel at a private meeting on Friday, in a final effort to avert the job losses and a devastating hit to the Port Talbot economy.

However, Unite, another union representing steel workers, publicly came out against the possible job cuts in the alternative plan.

The Indian-owned Tata Steel is considering shutting down the vast majority of work at the Port Talbot site, which is capable of producing 5m tonnes of steel a year, as soon as March. It plans to build greener electric arc furnaces, but they would only begin operating in 2027, and would require far fewer workers in the long term.

The Tata plan appears to have the backing of the UK government, which has pledged £500m to help it transition to electric arc furnaces, and which is negotiating a similar deal for Scunthorpe’s two blast furnaces. However, unions, local politicians in both places and the Labour party have argued that the government should insist on job guarantees.

The Syndex proposal for Port Talbot instead calls for a two-stage transition to electric arc furnaces that would protect 2,000 jobs , the Guardian can reveal.

During the first phase, one of the blast furnaces and the parts of the plant that that process molten iron into coils of steel would remain open. That would allow the company to continue to produce purer steel required by its automotive customers, such as Nissan’s Sunderland factory, and by food tins for the baked bean maker Heinz. The blast furnace would also be able to produce iron for use in the first of two potential electric arc furnaces alongside scrap metal.

Under the alternative plan, Tata would close the second blast furnace in 2032, when another electric arc furnace would be built.

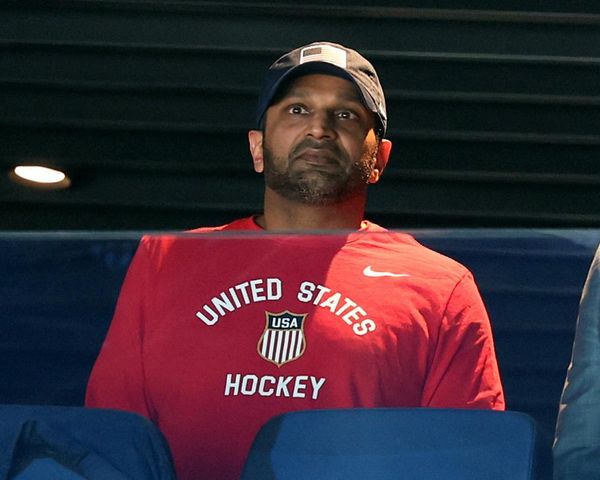

Alun Davies, Community’s national officer for steel, said the talks with Tata had been positive. When asked about the details of the plan, a Community spokesperson argued that it could be achieved with “no compulsory redundancies” and that it is “credible and deliverable”.

Community said workers and “most of Tata’s own management team” opposed the Tata proposals and “industry experts agree that it is doomed to fail”.

The spokesperson said: “The unions want to work with Tata and the government to make the business prosperous and sustainable protecting crucial jobs for generations to come. We are ready to play our part, but we will not stand by and watch the decimation of our industry and communities.”

Charlotte Brumpton-Childs, the national officer for steel at GMB, said the Syndex plan was “credible, workable and will secure decarbonised steelmaking in south Wales – as well as further down the supply chain.”

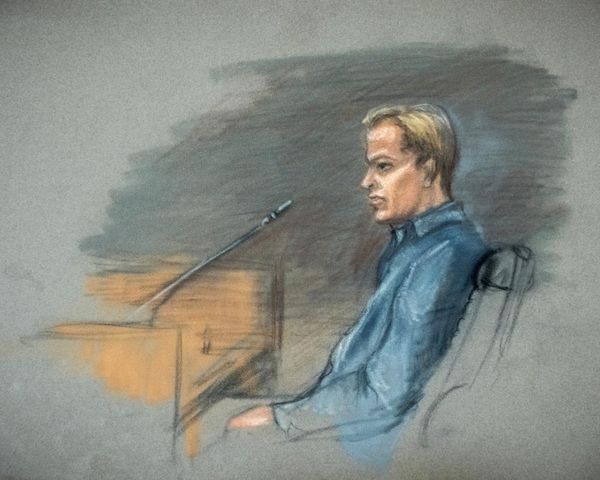

However, Unite’s disapproval is likely to complicate talks with the company. The Unite general secretary, Sharon Graham, said the union “does not accept the need for one single job to be lost”.

A Tata Steel spokesperson said the company would review the union plan, and “will give it full consideration before entering into formal consultation with our employee representatives”.

The union analysis is thought to argue that Tata’s plan to build a single large electric arc furnace would be technologically challenging, and that Tata may struggle to secure enough of the high-quality scrap metal the company plans to melt down. The unions are also thought to have argued that keeping a blast furnace open and building a smaller electric arc furnace initially would reduce the risk of delays to connection to the UK’s electricity grid.

The plans being considered by Tata Steel and British Steel, the Chinese-owned company that runs the Scunthorpe works, would be a landmark moment in British industrial history. They would leave the UK without the ability to make steel from iron ore at large scale for the first time since the start of the industrial revolution.

Community and GMB are arguing for investment in extra technology, called direct reduced iron (DRI), that would eventually be capable of making iron from ore using zero-carbon hydrogen.