TSMC was ahead of Intel with the adoption of EUV lithography tools for mass production, but when it comes to High-NA EUV systems, it looks like the company is behind its American rival. While Intel is already using its ASML High-NA EUV machine for R&D purposes, intending to use High-NA EUV lithography in the next two or three years, TSMC will only begin installation of its first High-NA EUV tool for R&D later this month, according to reports by DigiTimes and United Daily News.

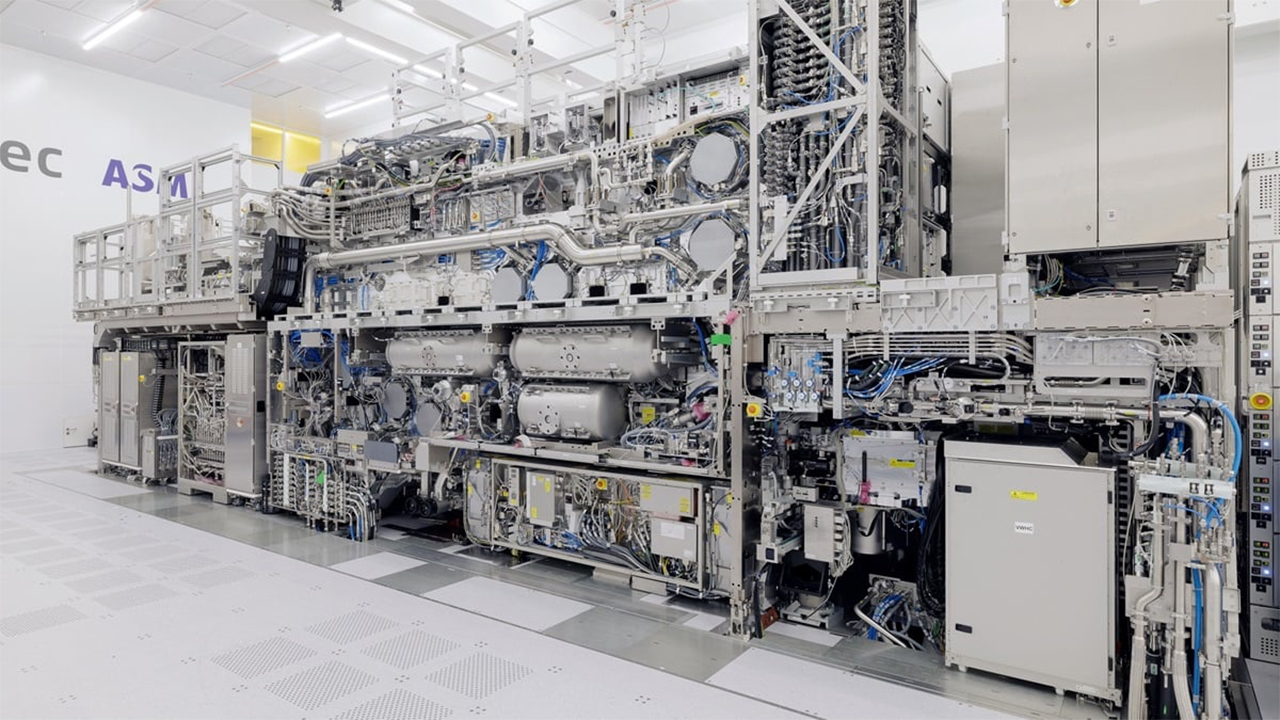

TSMC's first ASML Twinscan EXE:5000, a High-NA lithography system designed specifically for R&D purposes, is set to be installed at TSMC's global research and development center in Hsinchu, Taiwan. The world's No. 1 contract chipmaker will begin to receive components of the machine later this month. It is going to take TSMC several months to assemble and calibrate the tool before it will be able to test the next-generation semiconductor production technology at its R&D facility in Taiwan.

TSMC's upcoming process technologies — N2 (2nm-class) and A16 (1.6nm-class) — will rely solely on traditional EUV equipment with optics featuring a 0.33 numerical aperture (Low-NA). The earliest opportunity for TSMC to insert High-NA EUV tools with optics featuring a 0.55 NA will be with its A14 (1.4nm-class) process technology sometime in 2028 or likely later, though the company yet has to confirm this. However, since High-NA EUV lithography tools reduce the reticle size by half, their use will introduce additional challenges for both chip designers and manufacturers, which is perhaps why TSMC is not exactly accelerating usage of High-NA EUV tools.

Another reason why TSMC is not jumping to High-NA EUV tools is because of their price. As the company's Kevin Zhang, who is in charge of the development of new process technologies, pointed out earlier this year: he liked the performance of High-NA tools, but did not like the price.

Each High-NA litho tool costs around $400 million, but TSMC's president, C.C. Wei, personally negotiated a near 20% discount. This price reduction was achieved by combining the purchase of the new machine with the purchase of other ASML gear. Keeping in mind that TSMC is already the leading user of EUV lithography systems, holding an estimated 65% of the global EUV production capacity, ASML is certainly inclined to make deals with the foundry as it is one of its largest customers already.