Acoustic guitars don’t have the tone-tweakability of electric guitars, so your choice of strings is especially important. The good news is that advances in string-making technology have granted guitarists more choice than ever before. But that very diversity also makes choosing the right set of acoustic guitar strings more daunting.

We join Jack Dunwoody, a product expert with Rotosound, to get his advice on what you need to know about strings to make an informed, tone-enriching choice the next time you string up your acoustic guitar.

Let’s start with the basics. The most common types of string for acoustic guitar are phosphor bronze and 80/20 bronze, terms that refer to the alloy used for the wrap-wire on the wound strings. What’s the difference between them?

“Mostly the tone. So phosphor bronze is a very even-sounding string. The middles come through very nicely, and they have a great sustain to them. And then the 80/20 has more of a scooped middle sound – we’d describe it as more of a ‘hi-fi’ sound – where you’ve got some very strong bass and a lovely crisp, crystalline top‑end.

“You can visually tell the difference by looking at the wire, as well, on the string: the phosphor bronze is a little bit more of an orangey colour, whereas 80/20 has a bit more of a yellow colour. Actually, although ‘80/20 bronze’ is the name that we give it in our industry, it’s actually brass – 80 per cent copper, 20 per cent zinc – hence the yellowish colour.”

The bronze alloy wrap-wire described in the previous question is typically wound around a steel core. Describe the role of the core and some variations in its design that you commonly see.

“Manufacturers will offer hex-core or round-core strings. Hex core is by far the most popular type of core in use nowadays because it gives you a really stable string, in terms of tuning. That’s because the hexagonal [cross-section] of the core allows the wrap-wire to grab hold of that and not slip. So that’s what we use at Rotosound. Purely for tuning stability, we found it works really well.

“The majority of your [wound] acoustic guitar strings will then just receive one layer of wrap-wire that gets wrapped around the core. And that would usually be one of the two materials we’ve spoken about: the phosphor bronze or 80/20 bronze. But the heaviest strings receive an additional wrap around them to build them up to where they’re thick enough but also flexible enough to work well on a guitar and sound right.”

Bronze alloy wraps are typically used on the wound strings, E, A, D and G. How do they differ from the plain strings above them?

“Yeah, when we’re talking about cover alloys like phosphor bronze and 80/20 bronze, those are just used for the wrap-wire on the wound strings. We choose those alloys for that role because they’re soft, which allows us to wrap them around the core easily, and because of their tonal properties.

“But you couldn’t make the whole string out of them because they’re so soft that if you actually put it on a guitar and tried to use it as one of the high strings, you’d be tuning it forever because it would just keep stretching and you’d never get up to pitch – it’s not suitable for that.

“So our plain [non-wound] strings tend to be tin-plated, high-tensile steel. It’s so hard and high-tensile it’ll hold tuning without breaking. It’s basically the same material as the core of the wound strings, but it’s not hexagonal, it’s got a plain, round cross-section.

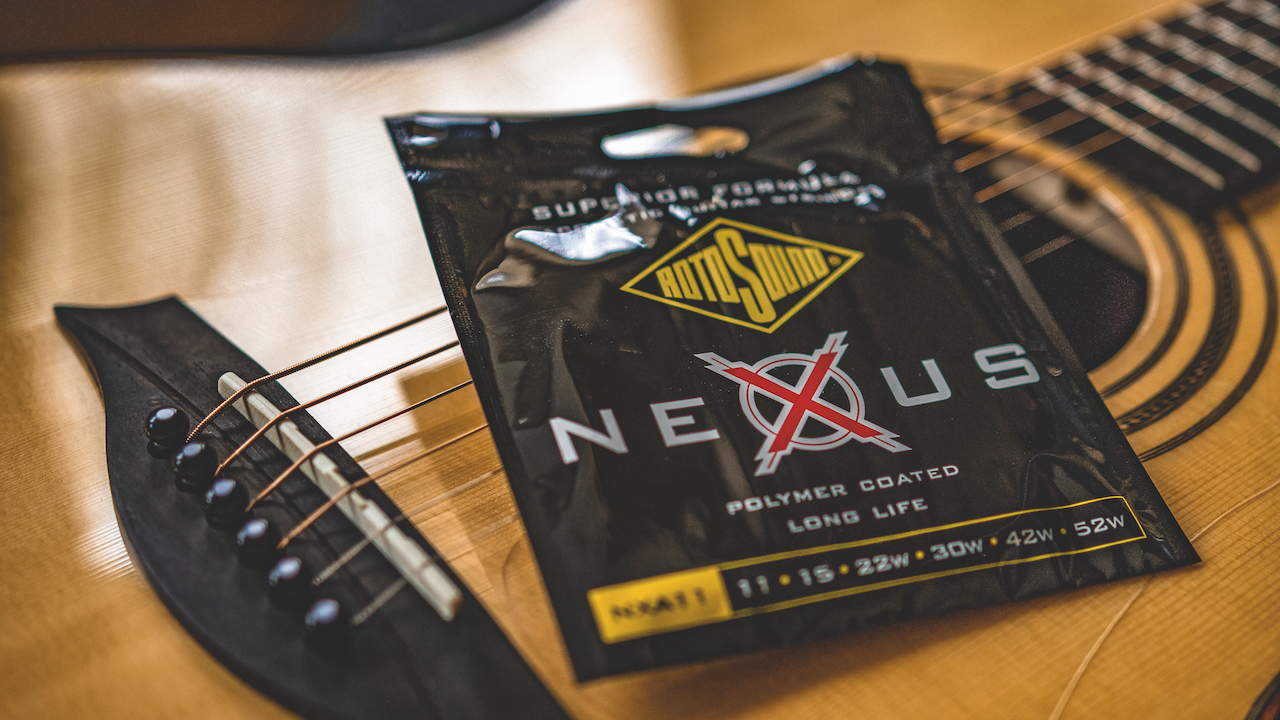

“However, with our Nexus acoustic strings, rather than using a tin-plated steel for the plain strings, we use a platinum‑plated steel instead for the plain strings because they are produced as a longer lasting string. So, for our Nexus set, we’ve chosen a plating that’s a little longer-lasting than the tin-plated steel equivalent.”

Nexus is a coated string set – what, in your view, are the pros and cons of coated sets versus traditional uncoated acoustic strings? Traditionally, their main benefit was supposed to be resistance to corrosion and hence a longer life.

Your fingers are not getting in contact with the core of the string, therefore you’re not corroding that part of the string

“Our Nexus strings use the same phosphor bronze wire that we use on our standard [uncoated] Jumbo King range, except in this case that wrap-wire comes from the supplier coated with a very thin layer of polymer. That then gets wrapped around the core, using the same process as we use for our normal uncoated strings. That means that we can use the same machinery, the same processes for making the strings, and that makes production a lot easier.

“But the main benefit of coating just the wrap-wire is that it feels more like an uncoated string. So you have the natural ridges that you’d have with an uncoated string when you run your fingers up and down.

“The tone is a little bit closer as well because you’re not kind of dunking the whole thing in [a polymer coating, as some makers do] – it’s not all completely restricted by the polymer coating, it’s just the winding. So your fingers are not getting in contact with the core of the string, therefore you’re not corroding that part of the string.

“For us, we feel that having the winding coated provides that protection, but it’s also a balance to give the normal feel of a string that’s uncoated.”

Given the benefits of coated strings, why do some players still opt for uncoated?

“I think the main reason would be the tone – there’s a certain brightness that you get with a brand-new set of uncoated strings that you just can’t get with the coated strings. However, I would say that over the lifetime of the string, once they’ve settled in, the coated strings are a lot more consistent for longer.

“My general view that I’ve got from working in the industry is that it’s more the players who prefer to keep strings on for a long time on their instrument who will go for the coated strings. They might not be picking their acoustic up every day. But when they come back to it, they want it to sound consistent over months. And you will get that with the coated strings.

“Another thing worth mentioning as well is finger noise. Some people really object to the sound of finger noise when they’re playing acoustic, and the coated strings definitely mitigate that quite a bit.

“Then again, we have a lot of artists who use our uncoated acoustic strings for recording, and many of them would say that they have to have uncoated strings, which they put on their guitar before they start recording a song. Even when it comes to the next day of recording, they would put on another fresh set of uncoated strings because that bright sound is exactly what they’re after.”