Micron has finally added advanced EUV lithography to its DRAM production nodes as its newest process node enters pilot production. Unlike its competitors, Micron was in no hurry to use EUV lithography to make DRAM, so it is the last in the industry to adopt the most advanced technology available. This year, Micron began pilot production of DRAM memory on its 1γ (1-gamma) fabrication process, which will enter high volume manufacturing (HVM) next year.

Today, Micron's memory chip production uses process technologies that rely exclusively on DUV lithography. In contrast, both Samsung and SK Hynix have invested in expensive EUV lithography tools that cost around $200 million each, ultimately reducing cost. However, Micron has developed cost- and performance-competitive DRAMs at its 1α and 1ß nodes by using standard DUV multi-patterning, but the switch to EUV will improve economics with its newer node.

While Micron will be somewhat behind Samsung and SK Hynix with EUV usage, its EUV results look quite promising, according to the company: "1γ (1-gamma) DRAM pilot production using extreme ultraviolet (EUV) lithography is progressing well, and we are on track for volume production in calendar 2025," said Sanjay Mehrotra, Micron's chief executive officer, at the company's conference call with investors and financial analysts.

Micron pins a lot of hope on its 1γ DRAM process technology and hopes that usage of EUV will enable it to build the industry's smallest DRAM cell, which will be a major competitive advantage for its upcoming memory chips as it will enable the company to build the cheapest and more energy efficient memory devices in the industry. EUV will be a key enabler of such memory cells. What remains to be seen is how usage of EUV affects the performance of Micron's DRAMs.

Micron's 1γ DRAM fabrication process with EUV is being developed at the company's Hiroshima operations in Japan, where the first 1γ memory devices are made as part of the pilot production program.

Truth be told, Micron has been experimenting with ASML's Twinscan NXE EUV lithography machines for a while now. The company has been testing these tools by substituting some of the DUV flows of its 1α as well as 1ß nodes with EUV flows and gradually tuning them to get proper yields. By now, the company has enough experience to start prepping for mass production using EUV tools.

"We continue to mature our production capability with extreme ultraviolet lithography (EUV), and have achieved equivalent yield and quality on our 1α as well as 1ß nodes between EUV and non-EUV flows," Mehrotra said back in March. "We have begun 1γ (1-gamma) DRAM pilot production using EUV and are on track for volume production in calendar 2025."

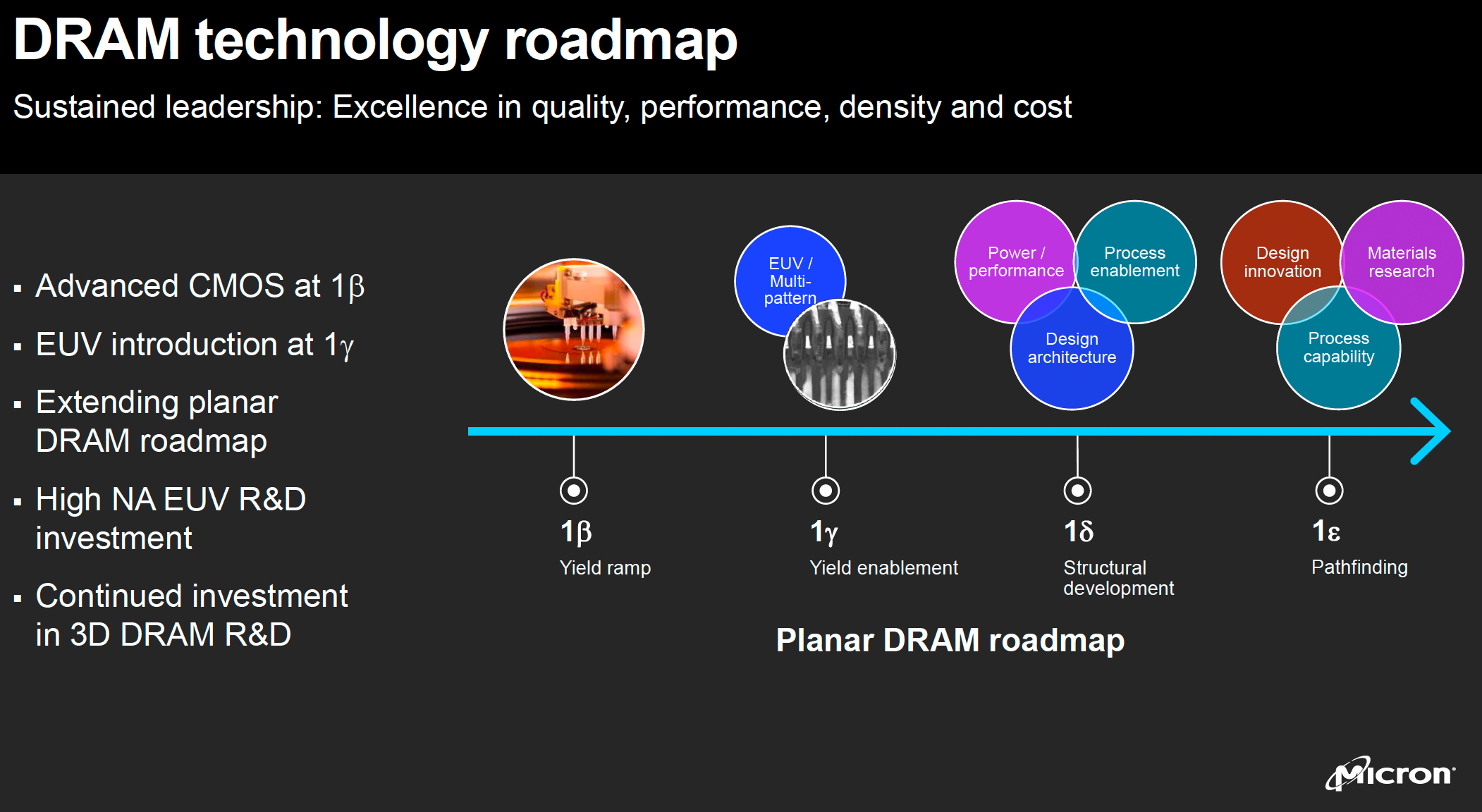

Beyond its EUV-enabled 1γ and 1δ (1-delta) production technologies, Micron is exploring 3D DRAM architectures as well as High-NA EUV usage for DRAM production in the coming years.