Image: PERUZA

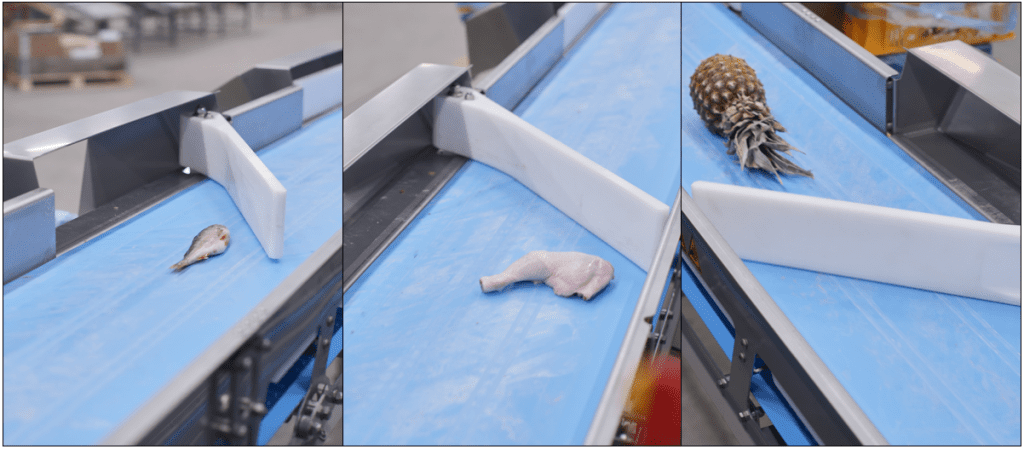

In the food industry, speed and accuracy are crucial especially when it comes to processing produce. The need to meet the high demand while maintaining a high standard of produce has never been more important than now. That is why Peruza’s Flow Weight Grader ensures that products are sorted accurately by weight and grade in order to keep the production line moving. The system introduces a conveyor system to move products across a series of different scales to weigh the products in real-time. Once the products have been weighed, they are then sorted into categories based on pre-set criteria to allow customization based on your particular needs.

Weight grading systems are crucial across all industries requiring precise weight grading such as seafood, poultry and meat processing industries. This is because the margin of error is incredibly low, with many businesses finding margins of error reduced to less than 0.1%. Another beneficial area is that these systems are found to increase processing line speed by up to 20-30%, allowing businesses to handle higher volumes without compromising on quality or accuracy. It’s really a no-brainer that in order to maintain the current increase in demand, Peruza’s Weight Grader is a must with its processing power of up to 120 fish per minute, making it one of the most efficiency fish grading equipment.

What other Fish Grading Equipment is Useful?

As mentioned previously, the need to stay up to date with modern technology is crucial in the fish grading game. While Peruza’s Weight Grader is an industry favourite, there are other cutting-edge technologies that Perzua has introduced to the industry:

Peruza’s Fish Weight Batching Line

This machine is designed for flexible batching needs with high capacity and speed. It can be used for any product that must be packaged at a certain weight but is specifically useful for fish, meat and vegetables. The machine uses a horizontal product distribution allowing no damage to the product itself while maintaining a high accuracy of dosing the product. This Fish Weight Batching Line can maintain batches of up to 35 kg is easily programmable and allows changeable batches, allowing it to fit your specific needs. Doing this reduces material waste by as much as 10-15%, slashing costs over the long run.

Peruza’s Volumetric Batching Line

Peruza’s state-of-the-art volumetric batching line is designed to make sure each batch has the same volume consistently. This is crucial for products where the weight isn’t the main indicator of the quality, such as sauces and creams. Due to its high-speed nature, you can expect up to 20 batches per minute requiring only 6 operators that can tray fill 12 tons of product.

Peruza loves to create flexible equipment allowing the operator to customize the volumetric batching line to fit specific needs, from liquids to semi-solids. This Volumetric Grading Line can be easily introduced into existing production lines to minimize downtime and increase ongoing production.

Why are Fish Grading Equipment Necessary?

Fish grading is incredibly important to ensure the best quality product reaches consumers' shelves, just like all food industries. Flow weight graders were brought into the industry in order to speed up the fish grading process due to the high demand and regulations brought in by governments to keep products sanitary and fresh. Due to these regulations, companies require minimal risk and to keep the quality high, automated fish grading machines can do just that. It alleviates the risk of human error and possibly contamination by being customizable to the customer's specific use case. This saves money, lowers the failure rate, and allows businesses to meet strict regulations to avoid fines and hit customer expectations.

To allow the public to get high-quality fresh fish, companies need to adopt better fish grading equipment to improve their grading lines. With high-performance equipment, the value received by all stakeholders will increase dramatically.