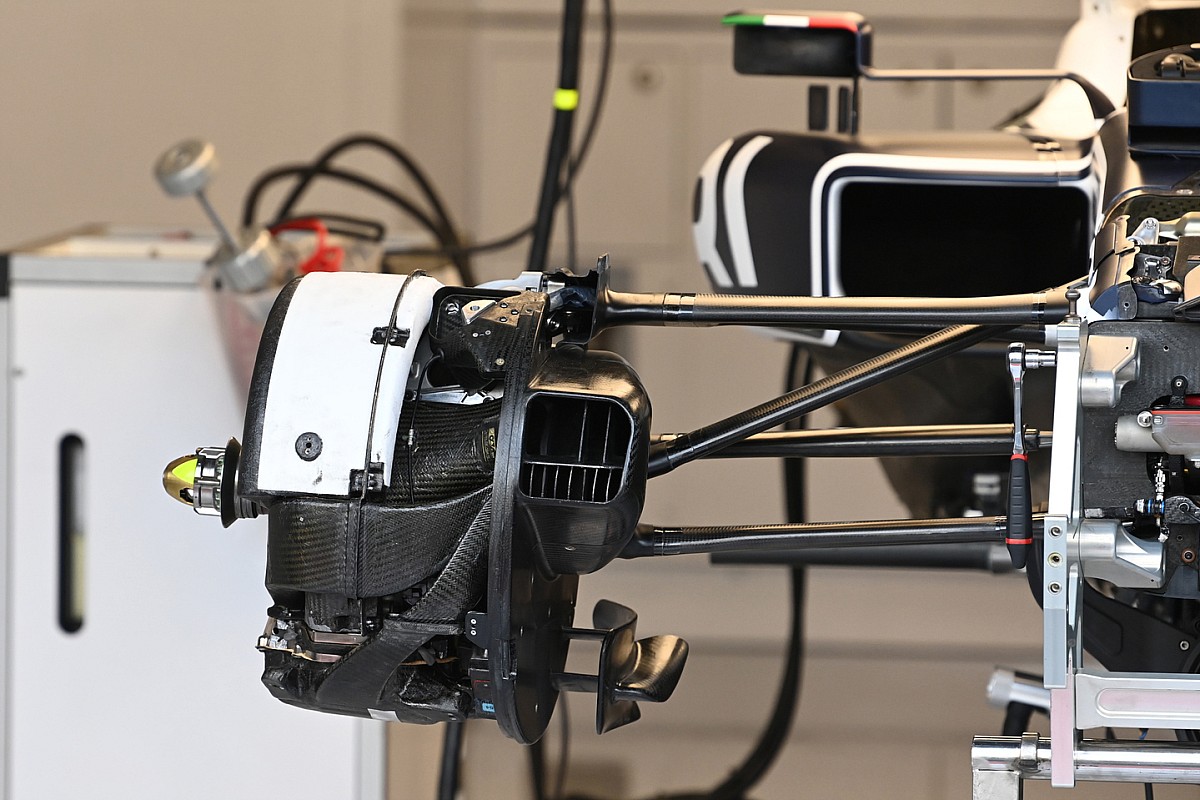

But some areas of the cars required a deeper analysis to understand their implications – with perhaps one of the biggest being the shift in size of wheel rims from 13 to 18-inches.

This change created a knock-on effect to the design of several other components, with the FIA making efforts to clamp down on the use of tricks that teams had used in the past to better manage airflow in this area.

Firstly, it’s worth noting that teams had been finding pockets of performance from the design of their wheel rims for some time now.

Not only was the number, shape and positioning of the spokes critical to the rim’s structural integrity, but these elements were also being optimised for heat dissipation.

Add to this a clear intent by the teams to help mitigate heat transfer from the brakes to the tyre’s bulk temperature via the wheel rim, thanks to the use of knurling and fins on the rim’s surface, and you can see how their abilities might be quashed by the introduction of a single supplier of a specification design. In this case it was BBS.

The larger diameter wheel rim also posed a new challenge in terms of the size of the wheel well, resulting in the brake drum being increased too.

Under the drum, there was also the brake discs to consider, as they had previously been a maximum diameter of 278mm for both front and rear assemblies.

From 2022 onwards, however, they could be between 325mm and 330mm for the front and between 275mm and 280mm for the rear.

Meanwhile, the addition of a minimum 3mm diameter for the drill holes would also have an impact on the disc’s performance.

Added to this too is the fact that the FIA had taken steps to prevent teams from passing heat and airflow out through the wheel face.

Instead, it required that they employ a rearward-facing outlet on the inboard brake duct end fence.

The reasoning behind this was not limited to the rejection of heat but instead that teams had, through various design mechanisms, used the assembly as a bypass to improve aerodynamic output over the last few decades.

Some have had more focused systems, such as blown axles, but almost the entire grid had settled on at least diverting airflow through passages within the brake duct that didn’t have a role in cooling the brake components.

Of course, this helped to manage the turbulent wake created by the tyre and therefore posed a threat to the overall goal of the new regulations.

As you’d expect, the teams looked into various solutions to help improve heat and airflow management for their brake assemblies, with many of the teams opting for a fairing to enclose the brake disc and isolate it within the now larger brake drum.

Red Bull’s disc fairing evolved over the course of the season, with modifications made to the shape of the fairing, whilst a coating was applied to its surface to help with heat transfer.

The coating was also employed on the caliper for the same reasons. The team opted for a similar solution at the rear of the car too, albeit with a smaller fairing to match the disc size.

Ferrari opted for the more conventional route in 2022 and decided not to cover its discs with a fairing.

Mercedes went for a more involved solution, creating an internal swirl pot to collect and direct the airflow and heat around the assembly before being routed to the rearward-facing outlet.

Alpine fell short of incorporating a full disc fairing but, having moved its caliper to the three o’clock position, it did opt to host a row of teardrop-shaped outlets in the accompanying caliper enclosure. This allowed heat generated by the disc an escape hatch towards the front of the drum.

McLaren encountered issues with the MCL36’s initial brake disc fairing when it arrived in Bahrain for pre-season testing, even though the troubles hadn’t been exposed in the test at Barcelona beforehand.

The team had to improvise and introduced a metal version that it ran until the Spanish Grand Prix.

Having overcome its initial issues with its first design, the metal disc fairing (left), was replaced with a new, much larger carbon fibre fairing at the Spanish Grand Prix.

Aston Martin, like Alpine, had opted to mount its caliper at the front of the brake assembly in the three o’clock position too. And, just like Alpine, the AMR22 also featured windows in the caliper enclosure in order to allow heat to filter through.

Alfa Romeo was another team to use a disc fairing to help improve heat and airflow management within the drum.

AlphaTauri, like its sister team Red Bull, also ran a disc fairing, albeit a half crescent solution, enclosing the upper half of the disc, whilst the caliper pipework crossed over the front lower half.

As you’d expect, given its close alliance with Ferrari, Haas opted for a more conventional arrangement, leaving its disc exposed within the confines of the main drum assembly.

Williams opted for a solution we’ve seen before, as its disc was sandwiched between two surfaces with a hood added to help control the airflow and heats passage under the drum.