The Creality K1C is the latest printer from Creality's fully enclosed K 3D printer line. Once again, the style of the machine reflects the rest of the line with a high-quality, rigid frame and a tinted transparent part-glass enclosure that keeps the inner chamber heated for specialist materials.

The K1C boosts the abilities of both the K1 and K1 Max with a few additional features over both machines. While the size and mechanical specifications of the K1 and K1C are essentially the same, some of the more advanced features, such as the AI camera, have filtered down from the larger machine.

Interestingly, Creality has completely overhauled the tool head with a 300° hotend that features a hardened steel nozzle tip designed to cope with specialist materials such as carbon fibre. This enhancement makes the machine far more appealing to those using 3D printers in the industry, reminiscent of the old Cel-Robox Dual and its specialist carbon heads a few years back.

While the K1C isn't a replacement for the K1, the price difference between the two is marginal, making it hard to see why anyone would now prefer the older K1 over this all-new and seemingly much more versatile new machine. The K1 and K1 Max impressed us two of the best 3D printers we've reviewed, so with the main mechanics of this new machine much the same, it all comes down to the integration of the new tool head and the AI camera to see if there's also a step-up in quality.

Creality K1C: Design

An initial look at the K1C, it's instantly apparent that this is closely related to the K1. The big difference here is that the K1C has been enhanced to handle carbon fibre filaments like PLA-CF, PA-CF, and PET-CF and features a hardened steel nozzle. Part of this new tool head design is Creality's development of what they call a "clog-free extruder kit" with a "Unicorn" tri-metal nozzle, which is a combination of copper, titanium, and steel that is more resistant to abrasive materials such as carbon fibre.

Part of the potential boost in reliability is due to the AI camera, which is now an integrated part of the K1C's design rather than an optional add-on, as with the K1. Further boosting performance is an upgraded cooling system with print head fans and an additional 18W fan in the build chamber to aid with cooling when needed.

As with the other K series printers, the machine utilizes a CoreXY design, which can be notoriously noisy due to the speed. A design change with the pulley gears means that these are now smaller, helping to increase the printer's precision. Staying with precision, a flexible PEI build plate is incorporated, and again, the machine uses a hands-free auto-leveling system. So far, in this series of printers, the quality of the auto bed levelling has been exceptional.

One of the most notable features of the design is the fully enclosed nature of the case. This has also seen a slight development over the K1 with a better handle, improved door hinge with magnetic closure, and an anti-shatter film added to the glass to improve safety.

Along with the other enhancements to the design, the touchscreen, while on the surface looking the same, has seen a few changes to accommodate the additional features of the AI camera and improved hot end.

Creality K1C: Features

A quick look at the features of the K1C reveals that the basics are much the same as the K1, with high-speed printing of up to 600mm/s, full use of the CoreXY motion system, and input shaping. However, the machine has had a few stability improvements, although it is a touch lighter at 12.4kg.

The big feature that is highlighted is the extended material compatibility. Although the nozzle and hotend temperature ranges remain the same as the older machine, the new nozzle and extruder mean that it can now cope with a range of specialist materials such as PLA-CF, PA-CF, and PET-CF, essentially any material with abrasive properties.

To cope with the new materials and more specialist options, such as nylon and ABS, the machine features a reworked cooling system. This now enables dynamically balanced fans to cool where and when needed, resulting in less stringing and warping.

Print Technology: Fused Deposition Modelling (FDM)

Build Area: 220 x 220 x 250 mm

Minimum Layer Resolution: 0.1 mm

Maximum Layer Resolution: 0.35 mm

Dimensions: 355 x 355 x 480 mm

Weight: 14 kg

Bed: Heated bed, up to 100°C

Print Surface: PEI flexible build plate

Software: Creality Print, Cura (5.0 and later), PrusaSlicer, OrcaSlicer

Materials: PLA, PETG, ABS, PA, ASA, PC, TPU, PLA-CF, PA-CF, PET-CF

Print Speed: Up to 600 mm/s

The new direct drive, clog-free extruder kit, and a unicorn tri-metal nozzle promise higher durability and performance. These have been enhanced to cope with high-temperature and abrasive filaments.

One of the features that appealed to me about the K1 Max or the upgrade kit for the K1 is the AI camera for real-time print monitoring, timelapse recording, and failure detection. This camera has been designed to fully integrate with the Creality Print software and, with the wireless connection, enables you to send and monitor prints to the machine remotely.

One of the standout features of the new series is the enhanced touchscreen interface, which is well thought out across the range of printers and enables you to make real-time adjustments and monitor print times if needed. As interfaces go, it's both intuitive and easy to navigate.

When it comes to the print area, the volume of the K1C remains the same as the K1 at 220x220x250mm with a PEI flexible build plate that supports input shaping.

A nice touch with the K1C is the option for a side-mounted spool holder, which gives you a few more options regarding the machine's positioning.

As a fully enclosed printer, the machine comes almost ready to go out of the box, only taking a few minutes before you can power it on and start printing. The build quality of the full metal frame, glass door, and acrylic sides all add to the feeling of quality that ups the level even when compared to the K1 and K1 Max machines.

Creality K1C: Performance

The print quality from both the K1 and K1 Max was on par, with the two machines scoring decently at 26.5. You can see the full performance in our Creality K1 review and Creality K1 Max review.

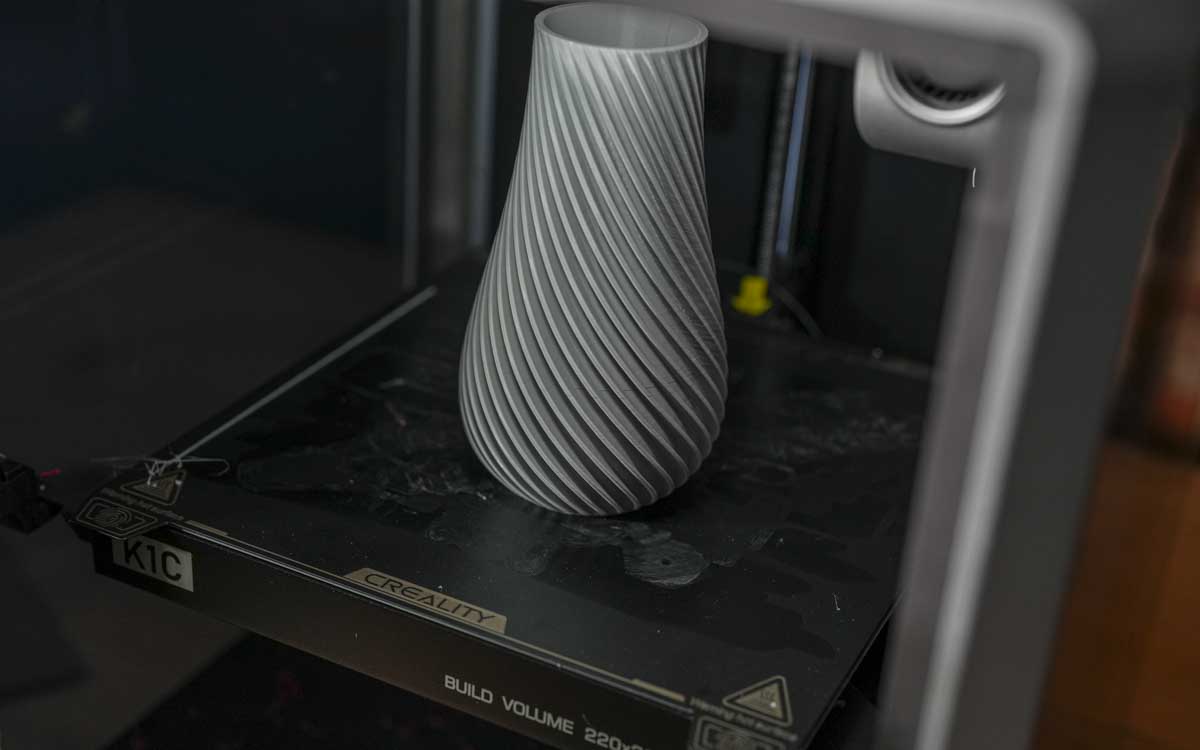

In the tests, the K1C looks to follow suit with a slight improvement in some areas. Starting with the real-world tests, the quality of the prints is exceptional, considering the speed at which the machine can produce a print. All models were produced flawlessly through three different material choices: PLA, PETG, and finally, Carbon Fill.

Looking closely at the PLA prints, the overall finish was good, with the new cooling system seeming to minimize stringing effectively. When using PLA, the top of the machine and doors are left open to aid with cooling. Switching to PETG, the filament enabled finer detail and a superb surface finish, although with both filaments, while the dimensional accuracy is good, the benchmark test showed some variation.

While the machine's performance is solid and would have stood out if launched alongside the other two, there are now machines like the Qidi Tech Q1 Pro 3D, which have slightly better overall print quality but lag in machine build quality and features.

However, this machine's main focus has to be carbon filaments, which are notoriously difficult to work with and can easily damage a standard machine. Here, the K1C handles the specialist materials with ease, producing excellent prints that are incredibly durable and well-finished. Carbon filament is not for generic modelling and is more suited for workable prototypes, for which this machine excels.

Creality K1C: Print quality

Dimensional accuracy - score of 5

Target 25 = X: 24.94mm / 0.06mm Error | Y: 24.97mm / 0.03mm Error

Target 20 = X: 19.96mm / 0.04mm Error | Y: 19.98mm / 0.02mm Error

Target 15 = X: 14.99mm / 0.01mm Error | Y: 15mm / 0mm Error

Target 10 = X: 9.93mm / 0.07mm Error | Y: 10mm / 0mm Error

Target 5 = X: 4.92mm / 0.08mm Error | Y: 5.04mm / 0.04mm Error

X Error Average = 0.052

Y Error Average = 0.018

X&Y Error Average = 0.035

Fine Flow Control - score of 2.5

Fine Negative Features - score of 5

Overhangs - score of 4

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 26.5 out of 30.

Creality K1C: Final verdict

Currently, the K Series of Creality 3D printers sets a comfortable benchmark for build quality. The machines look great, and the company has worked hard to elevate its offerings from run-of-the-mill 3D printers used by enthusiasts to machines that have a far wider appeal.

Compared to the Ender-3 series, which really brought the company to the forefront, the K series is far more refined and professional, breaking away completely from the DIY form that many of these printers originated from. The CoreXY design, combined with their speed and Klipper firmware, has boosted speed and quality, and the K1C is currently one of the most refined printers out there.

Looking at the benchmark scores, the printer performs well, putting in one of the highest scores of any FFF printer we've looked at. However, when it comes to print quality, there are now some very serious competitors. While the likes of QIDI and AnkerMake M5C might just edge ahead with print quality, neither comes close when it comes to the complete package.

The software for the QIDI is good but not as integrated as that of Creality, and the build quality needs to catch up. Meanwhile, the AnkerMake M5C produces outstanding prints but is still an open system and slower overall. The Creality K1C has it all—for education enthusiasts and professionals, this is one interesting printer. The only downside at present is that it still lacks any multi-material support from Creality, although that's likely to come.

Should You Buy the Creality K1C?

We've also tested out the best laser engravers