Chances are if you're an Apple (AAPL) loyalist then, you've potentially already placed preorders for Apple's latest low cost budget iPhone SE 3 or the new 5th generation iPad Air released during the tech giant's first product event for 2022 held earlier this month.

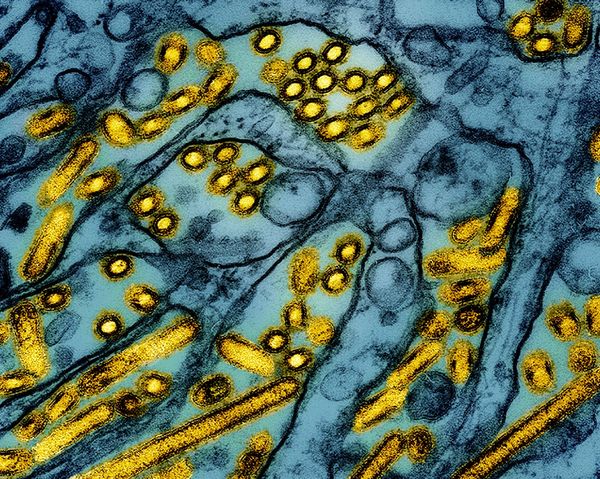

But news of a new Covid-19 outbreak in the industrial hub of Shenzhen earlier this week brought operations at Apple's largest iPhone manufacturing facility to a halt temporarily.

The news also hurt investor sentiment as market watchers said this could hurt Apple's production targets and potentially hit sales and revenue expectations.

While delivery times for Apple's slate of new products are already running into end March, Foxconn Technology Group has returned to "some production."

Foxconn formerly known as Hon Hai Precision Industry, has been able to restart some operations and production at its Shenzhen campus in a regulated manner.

The company has employed a closed loop management process in areas where both employee housing and production facilities are available.

"In applying this closed-loop management process within the Shenzhen campus and in implementing the required health measures for the employees who live on campus, some operations have been able to restart and some production is being carried out at those campuses,” a Foxconn Technology Group Spokesperson said in an emailed statement.

Foxconn added that it will continue to work closely with the relevant authorities in monitoring these operations very closely.

The company had said earlier that it was trying to minimize damage by deploying backup plants to keep up with production targets.

Apple did not immediately respond to requests for comment.

Separately, Foxconn is also said to be in talks with the Saudi Arabia government to set up a new jointly funded $9 billion manufacturing facility to reportedly make everything from microchips, to electric vehicle components, The Wall Street Journal reported.

In the past, production halts have resulted in a global chip shortage that impacted several sectors and continues to persist. As a result, manufacturing delays for products including smartphones, laptops, other electronics and auto parts have been felt by all major brands.

Although, last year, Apple's iPhone clocked record sales in the holiday shopping quarter despite a $6 billion-plus hit from supply chain bottlenecks.

When to Expect Your Next iPhone Delivery?

Foxconn’s production facilities in Shenzhen, in southern China, are considered a core hub for iPhone production as well as for some iPads and computers.

Wedbush analyst Dan Ives estimated that if Covid restrictions persist for two to three weeks it could hurt overall iPhone production by 1% to 2% for the quarter, in an interview with Yahoo Finance.

"It's concerning. The vast majority of production comes out of that factory. If this lasts longer than a week, it starts to become a concern. For now Apple could shift to other production factories across China, but it puts gasoline on the fire," said Ives.

Apple also has a large manufacturing hub in Zhengzhou in Henan Province in China where things continue to run smoothly.

Apple's iPhone Reported Stellar Quarter

Apple's December quarter numbers for its iPhone were off the charts led by strong demand for iPhone 13.

iPhone revenue grew 9% on a yearly basis to an all-time record of $71.6 billion. "We set all-time records in both developed and emerging markets, reached all-time high in the iPhone active installed base," Apple Chief Financial Officer Luca Maestri in the earnings call.

The company achieved these numbers despite facing higher supply chain constraints, caused largely due to the pandemic and then aggravated by a labor shortage, compared to the earlier September quarter.

The supply chain bottlenecks also point to a broken retail and inventory system that can barely handle a regular peak season in the holidays.