Over the last year, the rapid growth the e-bike market has seemed to gain even more pace. This progress has been aided by the huge developments in motors, batteries and componentry allowing bike manufactures to offer a much wider range of bikes.

One ‘component’ that is starting to become increasingly common is ABS, an anti-lock braking system. We spoke to Jack Pullar and Chris Astle of Bosch eBike Systems, and Fabio Todeschini, co-founder and CEO of Blubrake, to find out a little more about how it works.

The What and Why?

In order to improve safety and braking performance, ABS does two fundamental things. Firstly, the system stops the wheel locking and skidding, preventing the ensuing loss of control. Its other job is to stop rear wheel lift, which is caused when the front wheel slows abruptly, an occurrence that can send riders over the handlebars.

ABS is well established in the automotive and motorcycle industry. In fact, it is such a key component of road safety that it’s required by law in all but a spattering of countries.

So, why on e-bikes and why now? Quite simply e-bikes are taking more of us faster and with heavier loads than they ever did before. And with more riders – including novices who are encouraged into cycling by battery assistance – travelling with higher velocity there’s been an upturn in accidents relating to braking. Riders want to see it too.

Not only has ABS on e-bikes been independently proven to reduce wheel lock up and rear wheel lifts, it also improves braking performance, measured by the braking distance. And, of course, a shorter braking distance will reduce the risk of collisions, for example into a vehicle in front or a pedestrian stepping into the road.

Even so, for those of us still getting used to the electric motor revolution the introduction of ABS may come as a surprise. For others, like Fabio Todeschini, it’s a very obvious and natural progression to take the motorbike technology he worked with previously into the bike industry.

Similarly, the other current e-bike ABS manufacturer Bosch has been developing ABS in one guise or another since 1969 (albeit the first e-bike system is a little younger than that, first coming to market in 2018).

The How

Over to the experts to describe how the systems work. Fabio explains:

“In simple terms, ABS works by measuring the speed of the bike in relation to that of the wheels. This data is continually relayed to the control unit which is in turn linked to the brake caliper. If the system detects a wheel is slowing faster than the bike – a sign that it’s starting to lock up – it works to modulate the braking power by adjusting the hydraulic pressure in the caliper.”

As e-bike braking accidents are almost all consigned to front wheel skid or rear wheel lift then ABS, at the moment at least, is only fitted to the front brake.

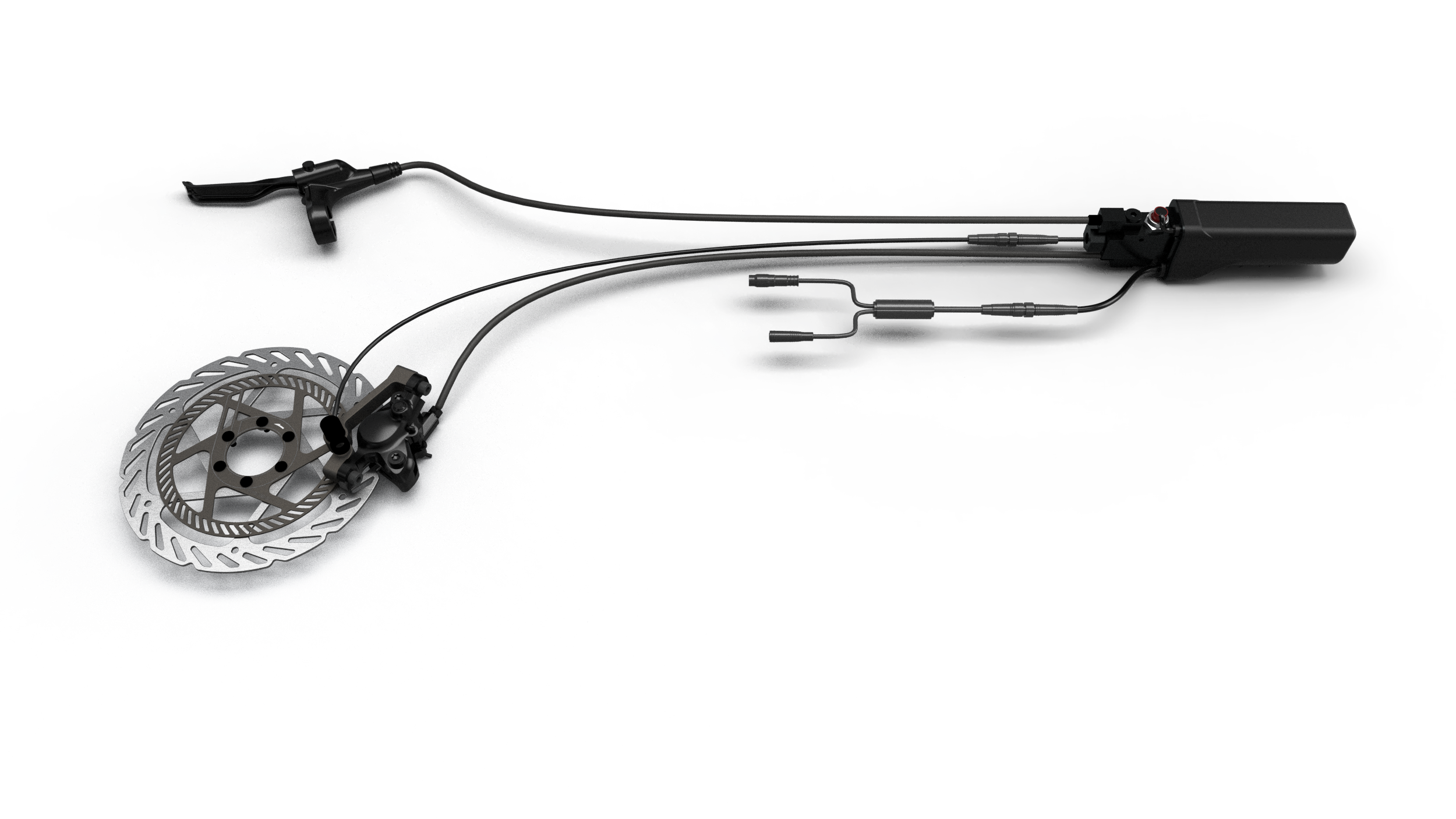

The Hardware

Fabio went on to explain that the ABS design on an e-bike is very close to a motorbike’s system, just smaller and specifically tuned. Given this technology is so well established, it shouldn't be surprising that there’s little variation between the systems of the two main manufactures: Bosch and Blubrake.

The most visible component of the system is the wheel speed sensor which looks like a secondary brake disc rotor (the phonic wheel) with a tiny caliper (the sensor). Bosch use a speed sensor on each wheel whereas Blubrake combines data from the front wheel sensor with that of the speed of the bike overall.

These sensors are hardwired into the control unit which is either hidden in the frame or mounted on the fork. The unit itself is powered from the bike’s main battery.

On top of these parts, there are some more subtle differences in the rest of the brake components compared to non-ABS versions - a bigger hydraulic reservoir is the most noticeable on these. Because of these tweaks, Blubrake and Bosch work in partnership with brake manufactures to develop the products.

The Software

Much more of the e-bike-specific part of ABS is what the software does and how this is tuned according to a range of factors. Jack at Bosch gave us more detail:

“The ABS is optimised for different bikes through an algorithm programmed into the control unit. This firmware takes into account how braking occurs on different bikes according to their weight, load, speeds, tyres and terrain, as well as the type of riding and rider.”

This means that in absolute terms ABS will modulate braking slightly differently in order to produce the same control on cargo bikes, pedelecs, hybrid e-bikes, trail bikes and others.

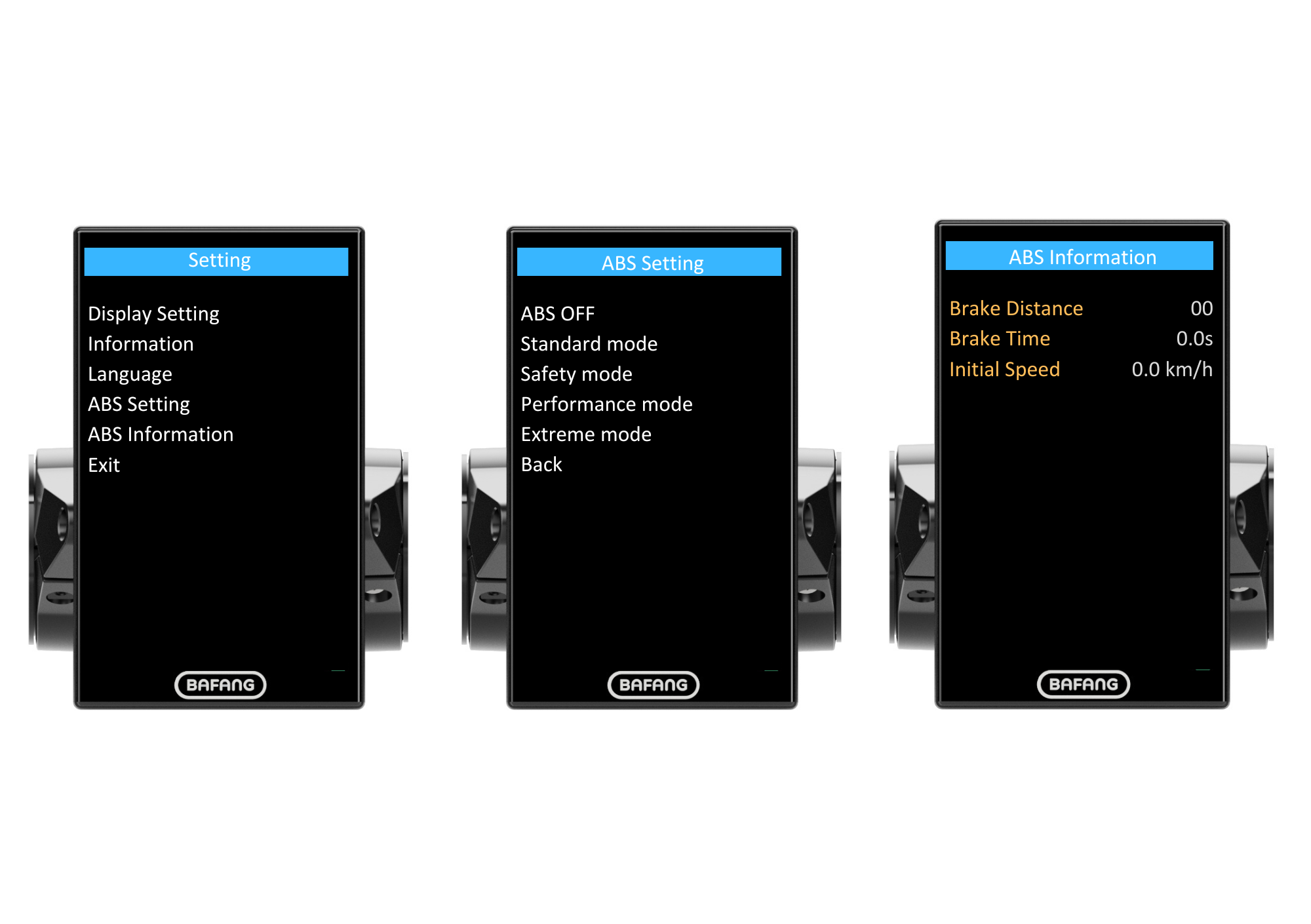

As well as this in-built tuning, there is the ability for a user to change the level of the settings to suit their experience and different riding situations. These settings are controlled through the bike’s main display where you can also retrieve your braking statistics.

This adjustment allows novice riders on fast and heavy pedelecs to maximise the capabilities of the ABS whereas experienced riders can maintain more control if they wish, with a step or two in between. Jack explained that this is particularly important for off-road riding where riders can use the brakes to deliberately load and off-load the wheels to help maneuverer their bike.

The Costs

Let’s start with the obvious downsides; weight and price.

Measuring the additional weight is reasonably easy, a single brake ABS adds around 400g to a bike. Working out the exact cost of ABS is harder as it’s absorbed into the total price of the bike, but it’s in the region of $/£500-600. It’s largely because of these two factors that ABS is only seen on higher end and more powerful e-bikes as there is less impact on the weight and price of the total bike (if you’re buying a 30+kg pedelec for over $/£10,000 you’re unlikely to be concerned about the additional weight and cost).

It’s also another reason that bike and ABS manufactures are focusing on front brake only systems and not adding even more weight and cost with a rear brake system, which would give rather more modest benefits. I can see this being a bit different in terms of Bosch’s system for MTBs where controlling rear wheel lock up and skidding could bring more significant performance benefits.

Perhaps more of a limitation than a real disadvantage is the law of friction. ABS can only stop you skidding by preventing you locking up the front wheel, it doesn’t make your tyres and riding surface any grippier. Put it simply, if you’re riding slick tyres on slippy surfaces you might still skid. What it can still do is lessen these to small skids which minimise the risk of you losing control of the front wheel or bike.

Any further shortcomings of ABS are rather more hypothetical than proven. I do wonder whether the design of e-bike brakes (big brakes and levers which encourage hard on/off use) combined with ABS will encourage riders to have a poor braking technique which will actually increases the risk of lock up and skidding and with it the need for ABS. This probably isn’t that likely, though, unless these riders are continually swapping between bikes with and without ABS which were of a similar weight and could achieve similar speeds.

There’s also always the issue of a system failure. From a safety point of view neither Bosch nor Blubrake think this would increase the risk of crashing. This is because the main reason for failure would be from a lack of battery power which would mean the motor wouldn’t be working to power the bike to the faster speeds where ABS is most active.

And finally, there’s also the cost of servicing and the availability of mechanics who have the appropriate skills. Yet again, this is probably not a huge issue for someone who is able to afford a high-end e-bike which will already need time and expertise to service.

The Ride

Our Tech Features Editor, Stefan Abram, has previous tried out both Blubrake’s and Bosch’s systems under comparable test conditions.

But a skid pan isn’t the same as the open roads (sorry, Stefan). So, I donned my crash test dummy suit and took to the tarmac, trying my best to crash Stromer’s ST3 pedelec, equipped with the latest version of Blubrake ABS.

Speeding off my first impression of the ABS was… nothing. Rather like an ABS system in a car, most the time you don’t notice it kicking in, well, except that you’re still upright after some deliberately hard front-brake grabbing whilst going too fast on a heavy bike. Whatever I tried on smooth tarmac, this remained the case, even as I upped the speed and the heaviness of my braking.

Then I took the slick-tyred 30mph machine off-road to see how it felt on slippery surfaces and whether I could defy the laws of friction. I tried wet concrete, damp grass, mud and gravel of various grades and yet, despite my best (and frankly quite scary) efforts, I never got close to losing control. The most I got was a couple of tiny stutter skids on wet grass and fine, deep gravel.

What surprised me most was how quickly I got used to the system, I could ride the bike at top speeds without giving a thought to how I'd stop safely.

The Future

Both Bosch and Blubrake predict that ABS will be standard on pedelecs and cargo bikes within only a couple of years. Given the safety issues and complex regulations already associated with them, I wouldn’t be surprised if it wasn’t long before ABS was a legal requirement for these bikes.

For Blubrake and Bosch the current focus is on working closely with bike and brake manufactures to enable more commuter and leisure style e-bikes to be equipped with ABS. Blubrake and Shimano recently launched a co-designed brake, and Bosch is now working with TRP and Tektro, building on its long-term partnership with Magura. These partnerships mean that most of the major brake manufactures will soon have an ABS brake in their ranges.

As with all tech, it’s likely we’ll see further refinement of both the hardware and software in the next few years which will likely further improve the refinement and sensitivity of performance as well as the weight and cost of the systems.

If you already have an e-bike and wanted to add ABS it’s bad news I’m afraid, it’s unlikely we’ll be seeing ABS available aftermarket anytime soon. This is mainly because the whole braking system needs to be designed to include ABS rather than it just be bolted on. There are also complex EPAC regulations which e-bike manufactures need to go through which complicate things.

The Verdict

You don’t need to look too far back – 2004 in the UK – when ABS was first made a legal-requirement for production cars. It was big news at the time but now we don’t give it any thought, the benefits far outweighing the costs, even for hardened driving enthusiasts.

I rather expect that in 20 years, if not much sooner, we’ll be doing the same with ABS on e-bikes. Whatever your personal feelings on e-bikes and technologies such as these, it’s hard to ignore the benefit that they offer especially if the current e-bike boom continues apace.