The U.S. recycling industry is starting to get a helping hand from robots, which can sort trash faster and more safely than humans, and artificial intelligence, which gathers valuable data about what's been thrown out.

Why it matters: Automation could help solve recycling's many problems, including the rise in hard-to-recycle plastic waste and consumer botch-ups that lead to contaminated recycling streams.

Driving the news: A new generation of trash-sorting robots with articulated arms and brainier vision systems is beginning to work alongside humans at recycling centers — a.k.a. materials recovery facilities, or MRFs (pronounced "murphs").

- The robots are getting better at culling recyclables from trash streams, which keeps the materials out of landfills.

- While still expensive — sometimes $300,000 each — the robots are coming down in size to occupy the same footprint as a human worker.

- "The robots improve the purity of the materials — they're just squeezing more value out of the stream," says Matanya Horowitz, founder of AMP Robotics, the leading company in this space.

On the software side, AI-driven optical technology can provide real-time data about waste stream contaminants — such as too much peanut butter left in a jar — and other metrics that are just being explored.

- "It's giving us this data so that we can make better decisions," says Matt Flechter, recycling market development specialist at the Michigan Department of Environment, Great Lakes, and Energy, which is experimenting with robotic sorters from Glacier and Machinex.

- His hope? Using that data to steer manufacturers toward more recycling-friendly product designs.

- "The vision will be, we will have real-time data about products to bring to the manufacturer, so they can say, 'Oh, we created a toothpaste tube that we thought was recyclable, but it turns out at the facilities the robots can't pick it up,'" Flechter tells Axios.

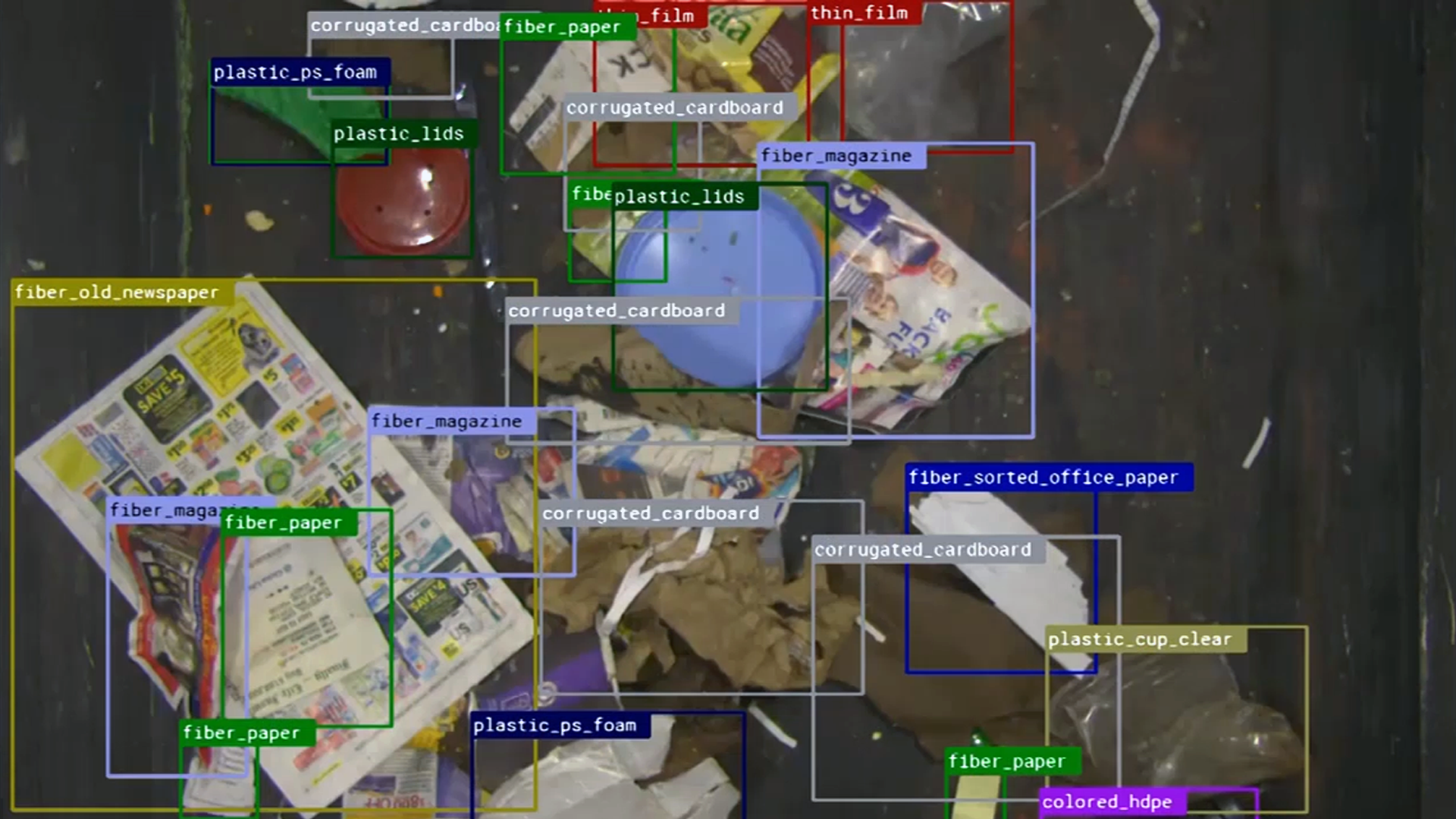

How it works: Robots train their AI vision on the waste stream and use their arms to suction out recyclables.

- "It's like a vacuum cleaner," Flechter says. "It knows what to pick up as things are coming across the conveyor belt. It's reading the optical signature of whether it's a yogurt tub, water bottle, paper bag or a milk carton."

- "You walk in and it's like a Rube Goldberg-type machine — conveyors going everywhere, robots picking off material, as well as all the people there."

Case study: Recycle Ann Arbor installed a sorting robot from Machinex called the SamurAI at its new MRF in November.

- The robot took three months to "learn" the shapes, sizes and densities of the materials before it was put into operation.

Yes, but: While it's sorting as fast as a human, its accuracy still needs work, Bryan Ukena, CEO of Recycle Ann Arbor, tells Axios.

- "We continue to tweak and say, 'No, this isn't the right item we want to pick — we want to pick this item,'" he said. "And so it's a process that you go through, but it learns."

- The longer it's on the job, "the more it knows your specific material because every community is a little bit different," Ukena said.

Between the lines: Recycling line jobs are monotonous, dangerous and hard to fill — and robots are starting to do them faster and more accurately.

- "A person will do about 40 picks per minute, but people will get tired," Horowitz tells Axios. "Our Cortex can do 80 picks per minute — the work of two people."

- This doesn't mean that people will be tossed out of jobs, says Rebecca Hu, co-founder of Glacier.

- "There's just not enough sorting capacity today to begin with," she tells Axios. "As you install more of these types of robots, people are getting moved to safer or more mundane parts of the operation."

Where it stands: These are early days, but AI recycling startups have lofty goals of boosting the circular economy and combating climate change.

- Glacier, which raised $4.5 million in seed funding last year, is building a "proprietary AI algorithm that's capable of recognizing over 90% of recyclables in the waste stream," Hu said.

- It's also fashioning "purpose-built, designed-from-scratch robots that can use that AI information to identify items, pick them up off of a moving conveyor belt, and sort them into the correct location."

- Glacier robots are "designed to fit anywhere a person can stand" and can be "installed in less than a day," Hu said.

- The payback — in terms of higher accuracy and more materials processed — can take less than a year.

Zoom out: Consumer product manufacturers are introducing new packaging all the time — lots of which isn't as recyclable as they think or claim.

- The new automation systems are able to adapt to these changes, to a degree.

- "With AI, our robot can in theory be installed today, and in five years when a company releases a new type of packaging that we've never seen before, we can train that robot to actually learn and go after that new type of packaging," says Hu of Glacier.

The big picture: Recycling in the U.S. has been beset by problems, from China's ban on importing waste to poor consumer compliance, a patchwork of local recycling rules, and the money-losing economics of running a recycling program.

- "Single-stream recycling, where all recyclables are placed into the same bin, has made recycling easier for consumers, but results in about one-quarter of the material being contaminated" and thus worthless to buyers, per Columbia University's Climate School.

Currently, buyers that want to create new packaging out of recyclables can't get as much suitable material as they'd like.

- With robotics and AI, "our real goal is to reduce the cost of sorting these materials as well as increasing their value," Horowitz said.

- "You improve the value by improving the purity of the commodity streams they are separating out, and also improving the specificity."

- "Ultimately we think it's important that the industry be able to take dirtier and dirtier materials if you want to increase the amount of materials that are recycled," Horowitz said.

By the numbers: The U.S. recycles 32% of municipal solid waste, up from 7% in 1960, per the Environmental Protection Agency.

What's next: Expect to hear more about "extended producer responsibility" laws — or EPR — which attempt to hold manufacturers responsible for the cost of recycling their products.

- They've been passed in Maine, Oregon, Colorado and California, and have been proposed in about a dozen other states.