Following the news of Schwalbe’s cradle-to-cradle inner tube recycling program, another German company announces its new sustainability program aimed at extending the lifespan of cycling products.

Ergon, known for its beloved saddles, bar tape and grips, introduces a new recycling program it’s calling GreenLab Circular, with the goal of making products that once they’ve reached the end of their lifespan can be recycled back into the same product to reduce waste.

"Our goal was to construct a saddle that comes entirely from a family of similarly-engineered materials, because only then is there the capability of completely recycling a product in its entirety," says Andreas Kraus Head of Technical Product Development at Ergon.

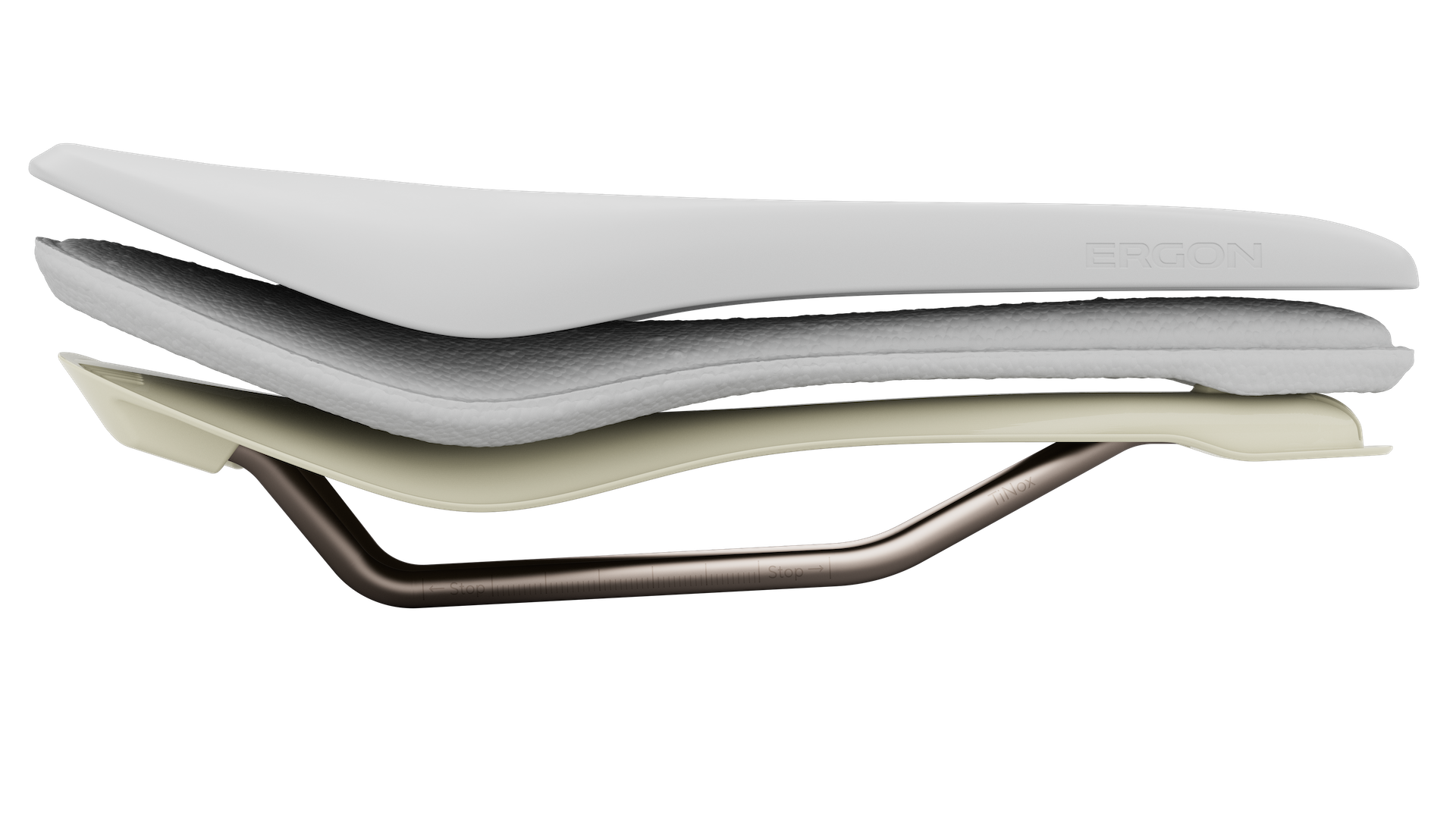

Ergon’s goal with the GreenLab program is to make products that currently have a finite usable lifespan —such as saddles— out of materials that are fully reusable for future products. They have achieved this with their first Circular product, the SR ALLroad Core Circular saddle, which was made in collaboration with the German chemistry company, BASF.

All of the components in this new SR ALLroad Core Circular saddle can be directly returned to the material cycle at the end of the saddle’s use. The saddle has a unique construction where all the plastic parts are made from BASF Polyurethanes and thus can be recycled in one piece. The saddle is still built with their CoreHD technology so the comfort and ride quality consumers have come to expect from Ergon remain the same.

Also read: Our review of the Ergon SR Allroad Core Comp men's saddle

The saddle rails are made from stainless steel and can be removed by hand, and Ergon has done away with dyes and a traditional cover instead opting for NovaCoat-D from BASF serves as a sustainable alternative to a conventional cover. This not only gives the saddle a unique look, it also makes the saddle easier to break down and reuse in the manufacturing cycle.

Ergon has plans to continue to expand the Circular product range with more products coming soon.