Not all that long ago it appeared that all FDM 3D printers were constructed in a particular way, with extruded frameworks, no real finish and looking somewhat DIY industrial. Not the sort of thing that fits well on a creative’s desk. This style of device still appears but a few manufacturers have begun to develop machines that look as good as the prints they produce.

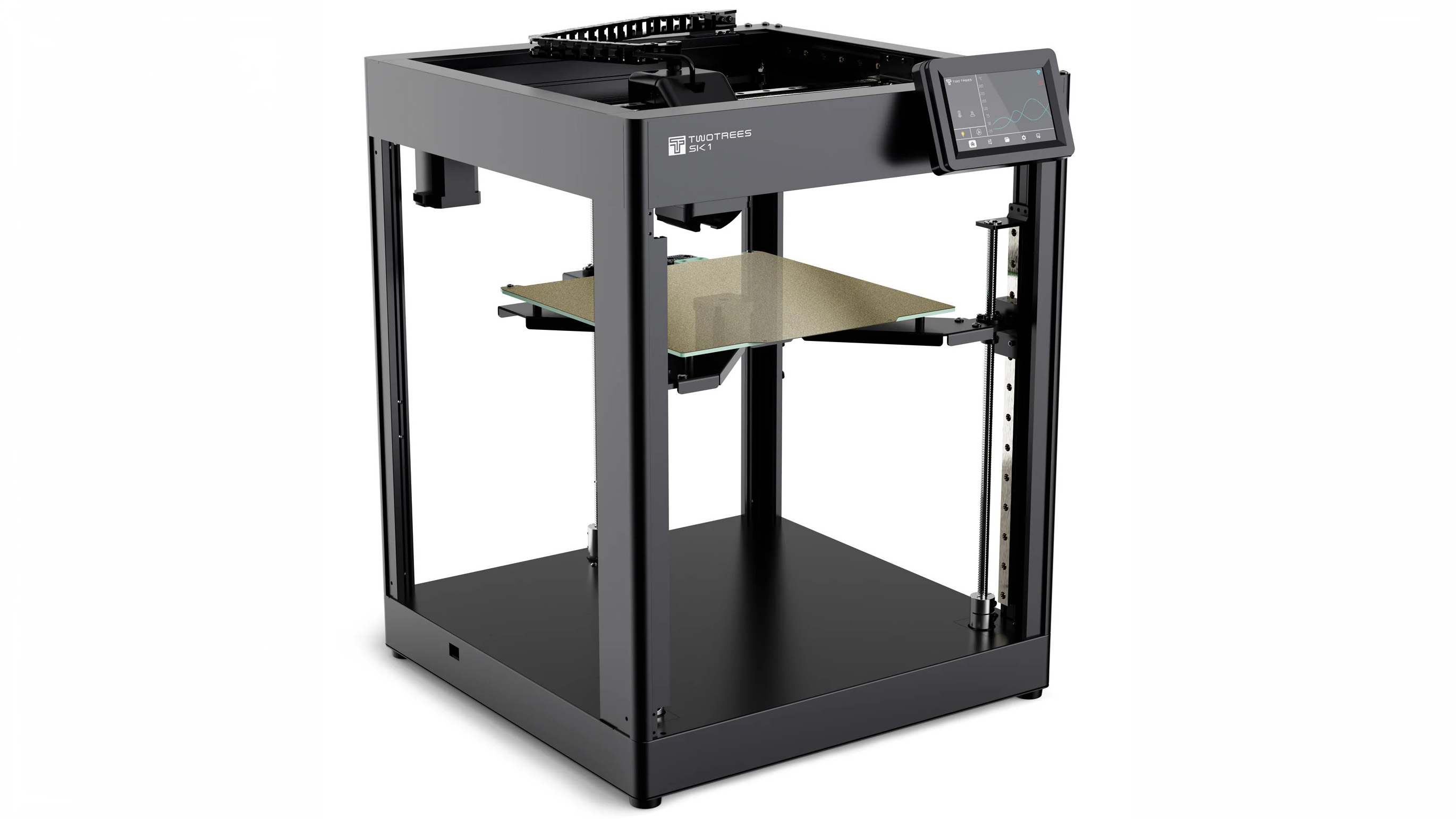

Two Trees is one of them, and their latest offering, the Two Trees SK1, is a much more ‘finished’ looking device with excellent build quality and materials. The gantry style frame is cuboid in form and solidly built out of the box, unlike others that need constructing.

Design and build

• 700mm/s print speed

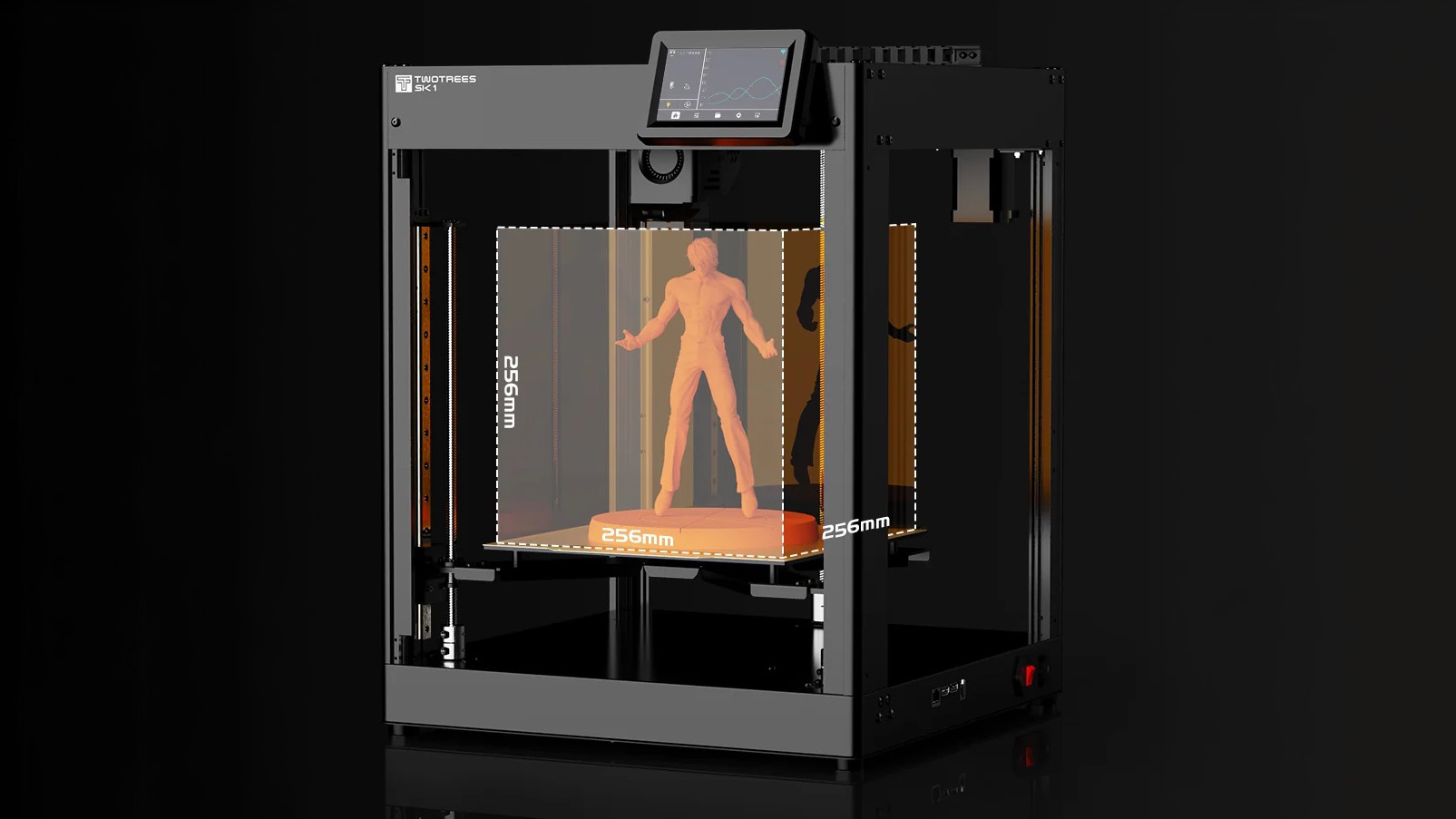

• 256mm x 256mm x 256mm build volume

• Wifi connectivity

• CoreXY translation

• Self-levelling print bed

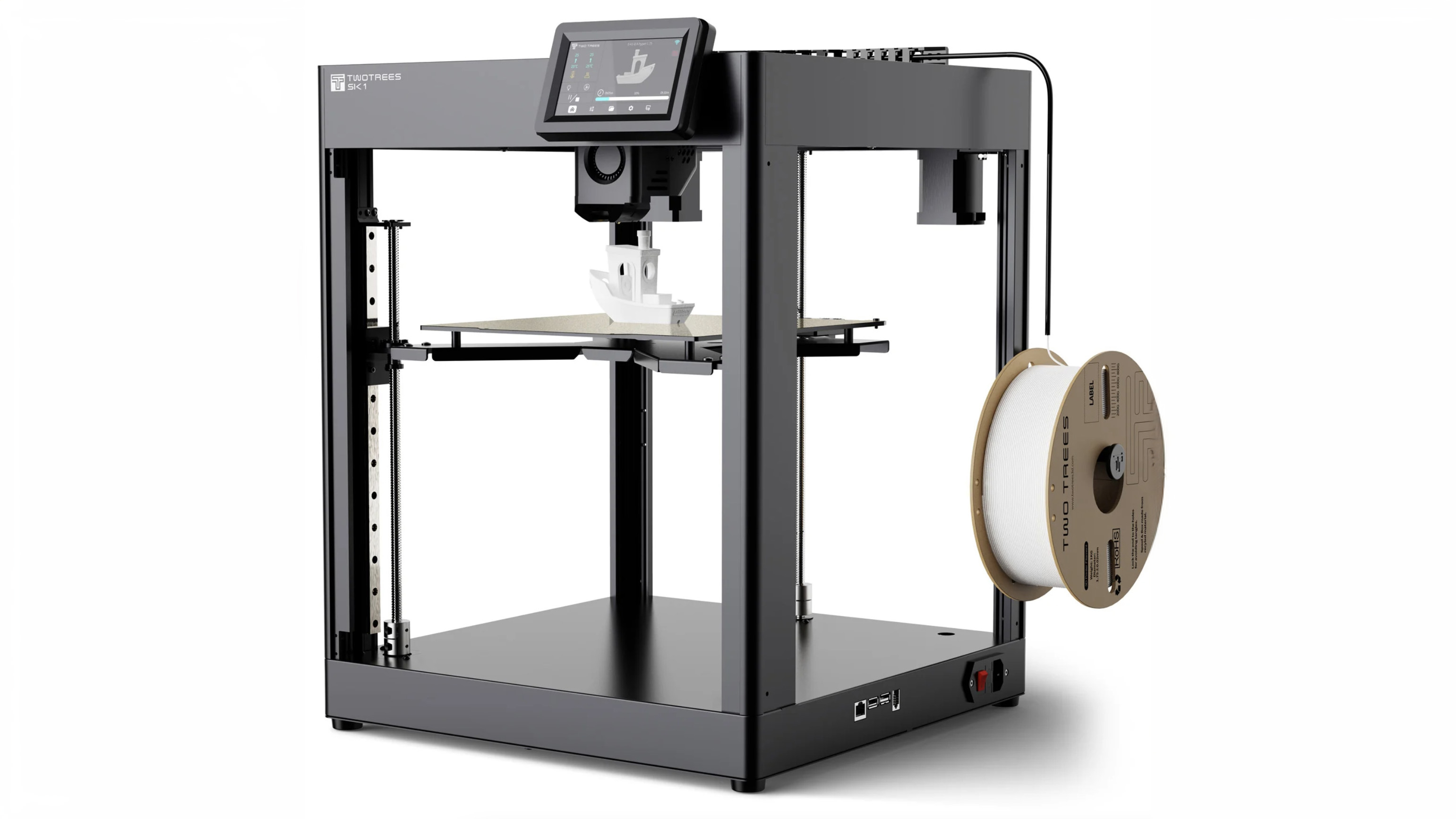

It comes almost ready to go out of the box. There’s a small amount of work to do before you begin your first print job, but it’s a simple case of attaching a few things, like the filament reel holder and the screen, and plugging in a few cables. All in all it takes around 15 minutes from start to finish. The build documentation is basic at best but it really isn’t a complex job needing an in-depth manual, and they do supply a QR code that takes you to the latest guide.

Once everything is in place you can get started and again, this is a simple job. The SK1 has a self-levelling print bed, so less faffing about here too. Most of the functions are accessed via the touchscreen controller, which sits on the upper front edge of the frame, a much better placement than some that sit too low down. The screen is of a decent resolution, so graphics and text all look crisp and easily readable.

Loading up the filament and getting it to the hot end is quick and the piping used, along with the gearing used to guide it, is excellent in feel and performance, something that is vital for any printer but even more so for one that prints at the speeds the SK1 can hit.

Performance and print quality

Not all FDM printers are built equally and not all will print all materials. Being able to reach differing temperatures, up to 300c, allows this printer to handle a wider variety of filaments and the SK1 supports more than many, from ABS to PLA. This means a single machine can handle more jobs, whereas some uses require multiple printers.

Those speeds are astonishing too. The SK1 can run at a top speed of 700mm per second, meaning print jobs can be completed in minimal time. Obviously there’s a balance to be drawn between speed and print quality, but in testing the SK1, even at the highest speeds, produced excellent results. This will be in part due to the CoreXY nature of the printer, as well as its Klipper firmware, which powers the motion of the components. On top of this is the overall construction, which is very rigid, along with the multipoint print bed levelling that keeps everything from shifting during a job.

Heat is a large part of a successful print too and certain materials require more, for both the adhesion to the print bed and the actual extrusion through the hot end. The SK1 caters well to both needs with a print bed that can reach 100C and a hot end that can hit a maximum of 300C, both suitable for most filament types.

Then there’s the matter of software. Before a print job can be sent to the printer it needs to be prepared, sliced and exported and many manufacturers, if not directly limiting software choice, certainly make it easier to use theirs. The ability to use whichever slicer you prefer is a nice touch here and means, for many, there’s no learning curve to speak of.

So what about print quality? I ran a few tests, from the obligatory Benchy to some of my own models, at various speeds, and it excelled in all. Yes, there are still some layer lines to be seen and these do increase at faster speeds, as does a little rounding of the very sharpest details. That said it’s minimal and cutting open a model shows that the higher-speed prints save with less clarity and detail internally. For most jobs this is never an issue and for those jobs where structural strength and integrity matter, running at a slower speed isn’t a big loss.