You may not be aware, but the centre of the known universe is located on an industrial estate in the town of Bletchley, just opposite Aldi. Or at least, to the right player, that’s how it feels. There, inside the long, low building with a grey and white panelled exterior, lies the Marshall factory. And with it the heart of the British amp-making industry – not to mention one of the world’s most important guitar brands.

The list of players that have used Marshall amps reads like a who’s who of rock’s cornerstone players: Jimi Hendrix, Eric Clapton, Jeff Beck, Pete Townshend, Eddie Van Halen, Randy Rhoads, Slash, Ritchie Blackmore, Billy Gibbons.

You can say the same of the list of products: from the JTM45, through to the Bluesbreaker, the ‘Plexis’, the JMP, the JCM800 and Silver Jubilee and, of course, those walls of black and white 1960 cabinets – the infamous stacks.

There is no denying its history, but Marshall’s star has faded a little in recent years as players new and old have moved away from heavy valve heads and full-stacks to mini amps and digital alternatives. Many guitarists still want a Marshall, of course, but the sound guy mic’ing your pub band does not…

So what can the Marshall Amplification of 2024 do about it? The brand is still, rightly, a source of pride and desirability – and represents surprisingly good value, given the quality of its UK-made output – but many of the products the company needs are not there.

Meanwhile, the Marshall name has proven its value well beyond the guitar industry, with the Swedish firm Zound Industries enjoying enormous success with a range of licensed Marshall home audio and headphone gear. Indeed, Zound’s offerings proved so popular that in 2023 the headphone producer was able to buy out the amp maker.

Now, the long-term partners are working in the same stable as the newly rebranded Marshall Group. The news has split Marshall fans, with some excited by the opportunity and others concerned about its future – particularly as amp sales now account for only five per cent of the combined group’s annual revenue.

This is why we’re now stood in the foyer of Marshall’s Bletchley facility in Milton Keynes. Later, we will ask new CEO, Jeremy de Maillard, about all of these things – and what he plans to do about them. But before then we’ve been given the chance to take a look around.

Factory Fresh

Steve Hill is the man tasked with giving us the tour. He heads up its custom cab builds in the Design Store and is a Marshall employee of some 31 years, so it’s fair to say he knows his way around.

“If it’s got ‘Made in England’ on it and was built after ’66, then it came from this actual estate,” Steve explains.

The firm makes roughly 450 units a week across two production lines and its hand-wired section. Steve says that everyone on the line is trained in all 50 builds from the current catalogue and they move between lines, too.

No-one is sitting around simply pressing switches, and we don’t see a single worker referring to a manual or following an instruction process; they do it all from memory and we see a huge element of hand-assembly, even on the builds that use machine soldering.

Steve says that many of the methods haven’t changed since he started there – and it’s pretty traditional in that sense, bar the odd automated soldering machine or part picker…

“When I started, I was making the old 12-watt amps, tiny combos,” he recalls. “We’d do 25 on a bench between two people. [I remember on my first day] someone came over and asked me if I was new. He showed me what to do and went off. Later, my boss came along and said, ‘You’ve done them all?!’ I said, ‘Yeah. The bloke over there showed me what to do.’ He said, ‘That’s Jim Marshall!’”

My boss came along and said, ‘You’ve done them all?!’ I said, ‘Yeah. The bloke over there showed me what to do.’ He said, ‘That’s Jim Marshall!’”

Steve Hill

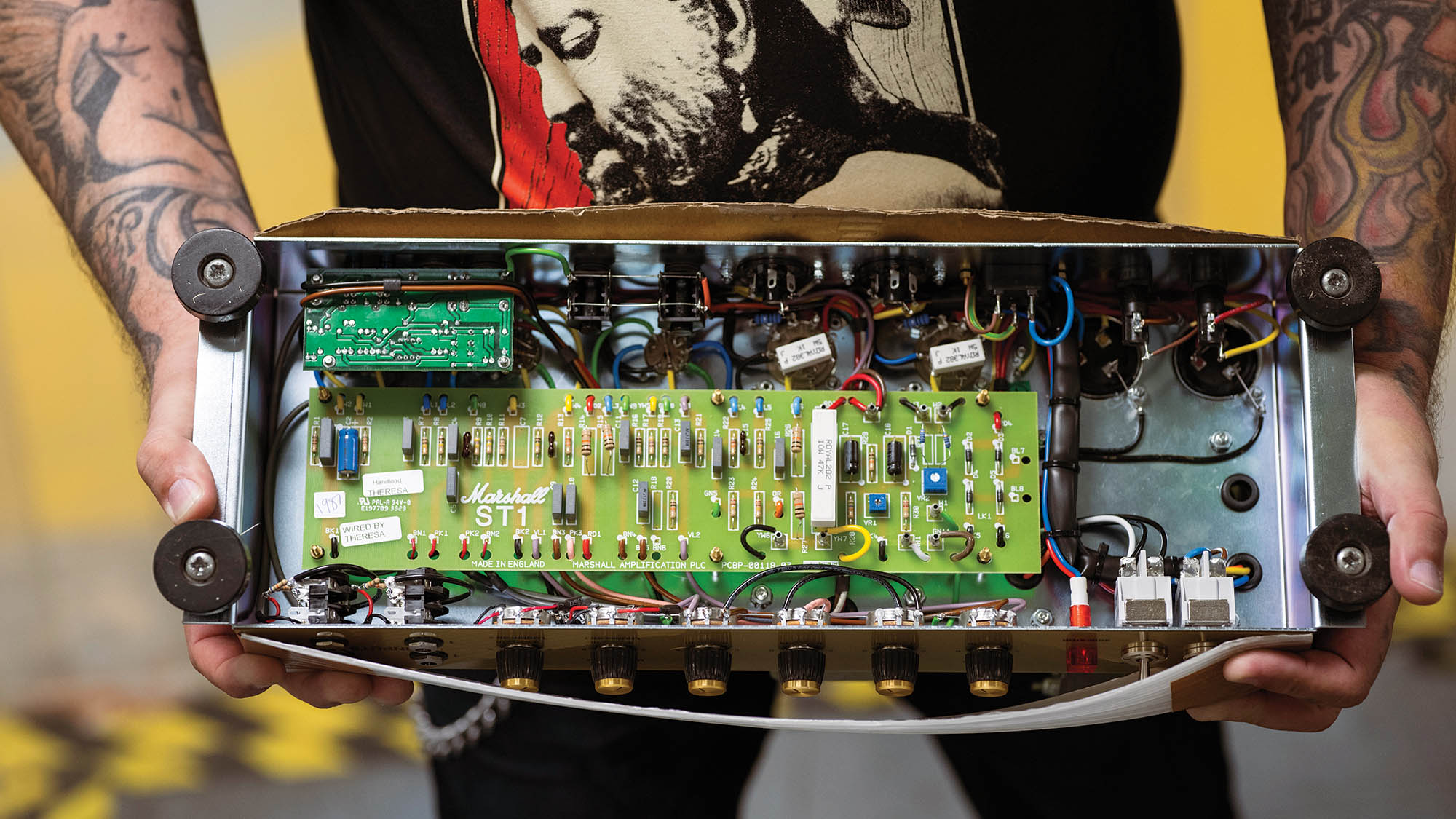

The best place to see a traditional amp build up close is the hand-wired section. The area consists of a series of small desks, rather than a line. Each one might be working on a different model and they’re all wired, start to finish, by hand. We see a 1987 (one of the much-favoured ‘Plexis’), alongside a more complicated JCM900 4100 getting soldered. Each one is then stickered with the name of its builder.

“People collect the stickers now,” says Steve. “We get tours in and the first thing people show me is a photo of the corner of their amp with the little ‘Made by’ sticker. Then we try to introduce them to the person that made their amp.” The valves and dials are added to the chassis before it’s moved through to finishing.

Steve takes us through to the wood mill. Here, beech ply arrives in large sheets and is cut, joined and sanded to form Marshall’s cabinets and amp-housing. It is the loudest room by far.

“Every one is hand-sanded [before being covered],” he explains. “And we do three different grades of paper, too.”

Back in the finishing room we watch as the glue-sprayed cabs are finally covered – in astonishingly quick time, again, by hand – and the iconic white piping is added before they’re all rolled along to meet the chassis and/or speakers for final assembly and testing.

We could spend hours here gawping at the variety of builds, but we’re conscious of our appointment with the firm’s new CEO, Jeremy de Maillard. We ask Steve – who seems genuinely enthusiastic about the new management – if the boss has got his hands dirty with a build and we’re told he has indeed. How did Jeremy handle it? “He did all right!” says Steve.

The New Guy

As Guitarist sits down with Marshall’s new chief, we report our findings. “Well, big words!” Jeremy laughs. “I’ve done different parts on different days. They make it look so easy because they’re so good. It’s like, ‘Okay, sit here and do that.’ And then… everything’s wrong!”

Jeremy de Maillard, by his own admission, might not be a production line super-sub quite yet and, indeed, he’s not a guitarist, either (though neither was Jim Marshall, of course), but he does not lack a sense of Marshall’s heritage – and the talent of the people in his employment.

“I’ve done that tour like 10 times now,” he tells us of the steps we’ve just taken around the factory. “I can’t get enough of it. To me, this is the highest level of craftsmanship you can have. I draw the parallel with Swiss watches or high-end leather goods. These are the people that are just the best at what they do. And they’re so proud of what they do.”

And it was with this expertise in mind that the new Marshall Group sought to discover what its employees really required – in the most direct of ways.

“We basically came in and asked the factory, ‘What do you need?’” says Jeremy. “Like, ‘Here’s a blank piece of paper. What do you need?’ The studio has been really well taken care of before our time, but [we wanted to know], ‘What do you need to make these the best facilities for either making products for guitarists or for the recording studio?’”

And the new group reportedly said yes to everything – alongside upgrading the staff facilities. Jeremy believes the firm has invested more in the past eight months than was spent in the 10 years prior to the takeover.

For all of Marshall’s aura – its talent and tradition – that investment is, to be frank, badly needed. The amp market of 2024 is unrecognisable compared with that of 20 or 30 years ago. The recent mini heads and cabs of the Studio series are a notable exception, but it feels like Marshall has fallen noticeably behind the competition.

We lay this picture out and are assured to hear that it is not news to Marshall’s new CEO. Nor is the fact that guitarists have been speculating over the implications of the merger – but Jeremy is keen to set the record straight.

“There are two things we’re very clear on,” he responds. “Number one is that we will forever cherish the valve, handmade, analogue product that we have – and will continue to over-invest in this. Even if it’s not the biggest part of the business. We will never let go of this.”

We know guitarists will be pleased to hear this, we note. “It is beyond protected,” he reiterates.

“All of the investment we’ve made here is to make that better. But at the same time, we also realise that we don’t have all of the products that the guitarist today expects of us – when it comes to more digital amplifiers, or digital products, in general.”

The hint is a tantalising one. Marshall might still hold its own as a valve amp builder, but in 2024 most players need and expect more than valves alone. If Marshall is truly to appeal to the mass market again, then it needs to address this quickly.

“We’ve been behind and now we want to catch up,” he acknowledges. “Our goal is to provide guitarists the best possible Marshall experience, no matter what their needs are. If you’re into valve analogue amps, we’ve got you. But if you want a practice amp or digital or desktop [solution], we’re gonna be there for you as well. Just give us a little bit of time.”

Jeremy de Maillard says that the results of the group’s present R&D efforts should really start to show in the next year or two.

“I’m super excited about this,” he enthuses. “Because everything we hear when we talk to the guitarist community is that they love the brand – they just wish they could use the brand in all of the occasions that they have to play guitar.”

Guitarist spent an evening reading Marshall forums before our visit and we tell Jeremy that players have felt frustrated in the recent past – and that they’re concerned about the amp maker being overshadowed by its home audio wing.

“If we lose this [Bletchley and the amp brand], we lose everything,” he says. “So that’s what we’re going to cherish first and foremost. That cannot go away. But we’ve got some catching up to do. We’ve got to go back and show the guitarist community that Marshall truly cares about them. To listen to them.

“We are on those forums as well. They keep us honest. It’s like, ‘Hey, tell us! No filter!’ We love this. We take it in and then we’re very self-aware of the things we can do better, and we’re working hard on it.”

Future Of Marshall

In that spirit, then, we list some of the things on players’ wishlists from a modern Marshall: among them a viable digital amp, something that crosses the line between the Bluetooth speaker and home amp, modelling solutions, software plug-ins, IR integration…

“Well, I don’t want to give away too much. But I would say all of the above is in the plans,” he grins. “Literally, everything you just talked about. But the order in which they’re going to come is going to depend on our ability to get them to the level that we are proud of.”

The Marshall exec says that we’re likely to see more Studio Series takes on the firm’s classic valve amps first, which makes sense as a signal to those concerned about the heritage. And while we’re back on the topic of valve builds, what is the likelihood of trying to win back some market from the Marshall modders?

Again, we’re met with a knowing grin – and a vague but enticing nod that “we are working on this”. The CEO won’t be drawn on the details at this point, but he acknowledges the idea of in-house mods came “very early into conversations” with the Bletchley team.

Ultimately, it’s an exciting and slightly frustrating discussion, but mostly the former. It’s clear the firm has some very big things bubbling, along with the intent and financial firepower to actually make them happen. But we’re going to have to wait a bit longer to see exactly what is brewing behind those panelled walls.

What is clear right now, though, is Jeremy de Maillard’s message to players: everyone at Marshall is listening, they get it and they have a plan to win hearts, minds and ears once more.

In the meantime, the CEO asks Marshall fans to keep letting the company know what they want to see – and points out that there are not many amp firms out there in the position to make this kind of investment. As we conclude our conversation, Guitarist is left feeling much more positive about the prospects for Marshall amps and players, too…

“The goal is to grow the whole pie,” Jeremy concludes of the newly merged business. “For me, [whether listening or playing,] it’s just an opportunity to get more people to love what we love. I think you feel the love and the passion when you spend time in this office. We want more people to be into this. That’s really what we’re about.”