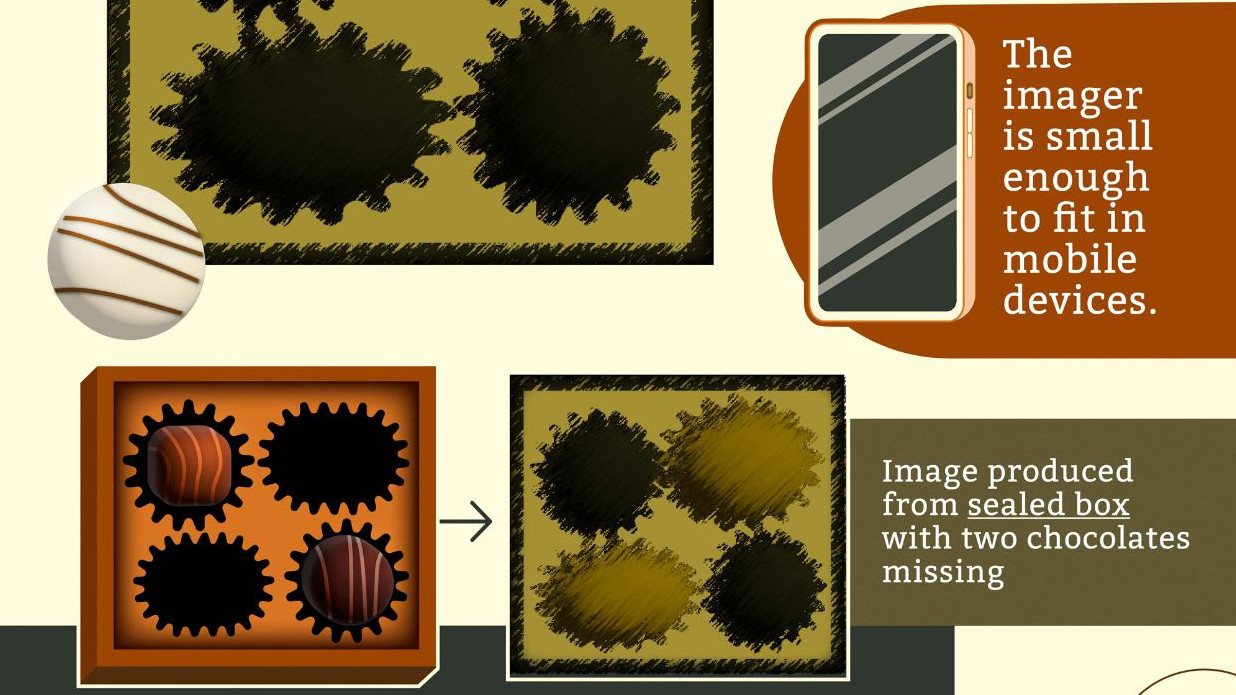

A Superman-inspired, CMOS-powered X-ray vision imager chip has emerged from the combined research of the University of Texas at Dallas (UTD) and South Korea's Seoul National University (SNU), per a release from UTD and a corresponding IEEE paper. This imager chip demonstrates the ability to see objects through cardboard from about an inch away — a deliberate distance restriction in the technology to prevent abuse, though a future version is expected to scan as far as five inches. The range restrictions here should be reasonable enough to prevent most worst-case scenarios, though those prone to taking naps in public places and the such may want to be especially cautious if these chips become commonplace.

The way this technology works is by emitting radiation within the terahertz (THz) range, which is invisible to the human eye. Early versions of this tech started at 100 GHz imaging (or 0.1 THz), but have progressed higher in the spectrum as refinement continues. For example, this particular version operates roughly in the 296 GHz range. The 2022 iteration of the technology, which is much larger, operated instead within the 430 GHz range.

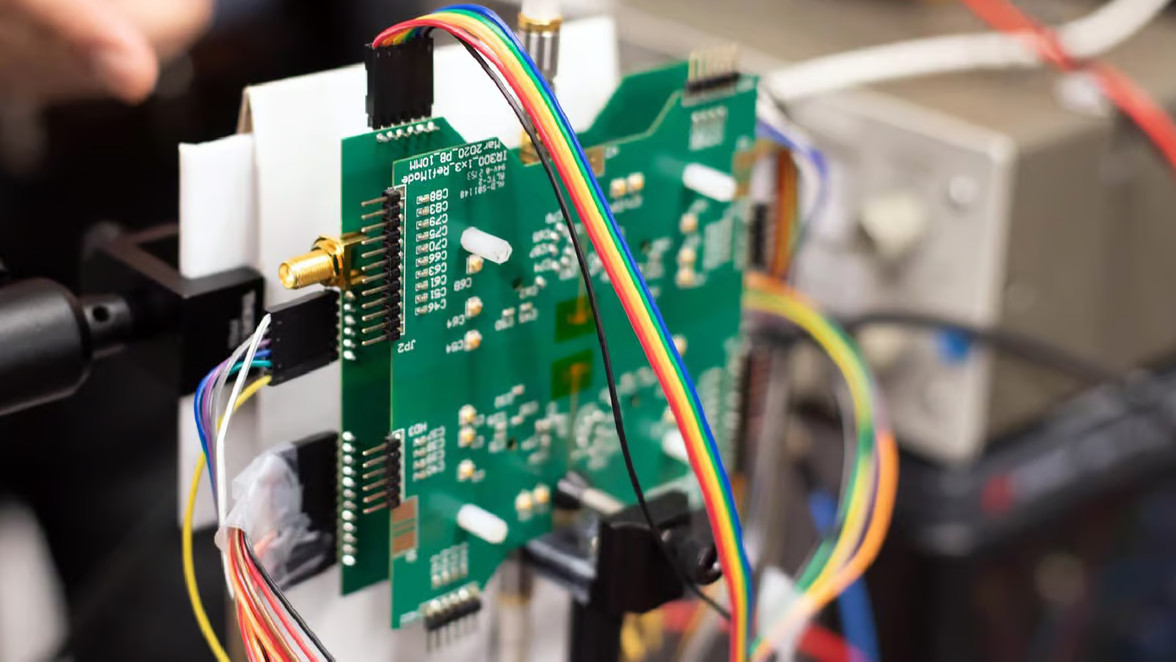

As it turns out, using a regular old CMOS (Complementary Metal-Oxide Semiconductor) seems to be an affordable and effective way to both generate and detect THz signals. The 2024 iteration of the researchers' X-ray imaging tech relies on a 1 x 3 array of 300 GHz, 0.5 millimeter "CMOS pixels", each of which are the size of a grain of sand.

Dr. Brian Ginsburg, director of RF/mmW and high-speed research at Texas Instruments' Kilby Labs, was quoted saying "It took 15 years of research that improved pixel performance by 100 million times, combined with digital signal processing techniques, to make this imaging demonstration possible. This disruptive technology shows the potential capability of true THz imaging."

The researchers behind this X-ray imaging tech hope to see it used in a variety of applications, but especially for detecting objects inside packages or walls. For example, construction workers, plumbers, and electricians could find studs, pipes, support beams, and wiring behind walls. Everyday users could inspect product packages before opening them, for example. They even claim medical applications might be possible — which may end up particularly cost-effective one day, considering how much a single medical X-ray machine costs today (as high as $200K, sometimes more).