When it comes to modern high-end saddles, 3D printing is where the innovation has shifted. That doesn't mean that 3D-printed options are dominant in our list of the best road bike saddles, they continue to represent only a small part of the market primarily because of pricing. 3D printing for production is still very new and the pricing represents that. Put the price aside though and it's this small part of the market that is driving real innovation.

Price: £319.99 / $379.90

Length: 255 mm

Width: 140 mm

Weight: 220g as measured

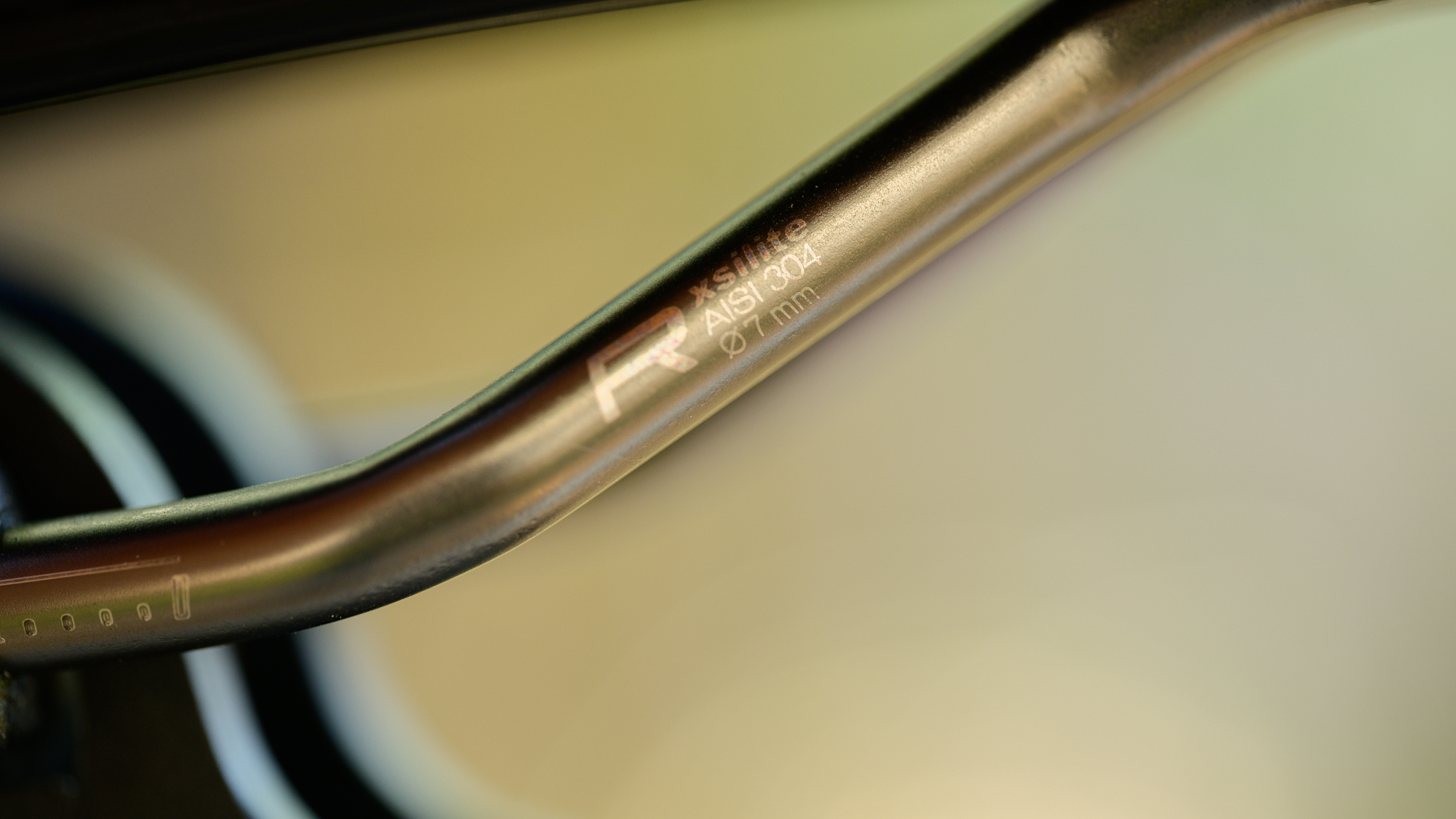

Rail: Round stainless steel

The latest company to join the group of options for 3D printed saddles is Selle San Marco. In November of last year, the brand announced the Shortfit 2.0 3D Racing saddle as a new range-topping option for the Shortfit 2.0 line of saddles. There are two options available depending on your preference for rail shapes and overall weight and we are just starting to see them both become available for sale. I recently had the opportunity to take the stainless steel rail option on an adventure through California while testing the FSA K-Force We 12s groupset and I'm ready to share the details about it. If you are considering a new saddle this summer, keep reading to see if the Selle San Marco Shortfit 2.0 3D Racing saddle might be right for you.

Design and aesthetics

Selle San Marco isn't the first to market with a 3D printed saddle. In fact, the brand isn't even close as Fizik and Specialized have both already moved to second-generation products. There's also no unique new take on the process of 3D printing. Like others before, Selle San Marco is using a process that employs a process called DLS or Digital Light Synthesis from the Californian brand 'Carbon'.

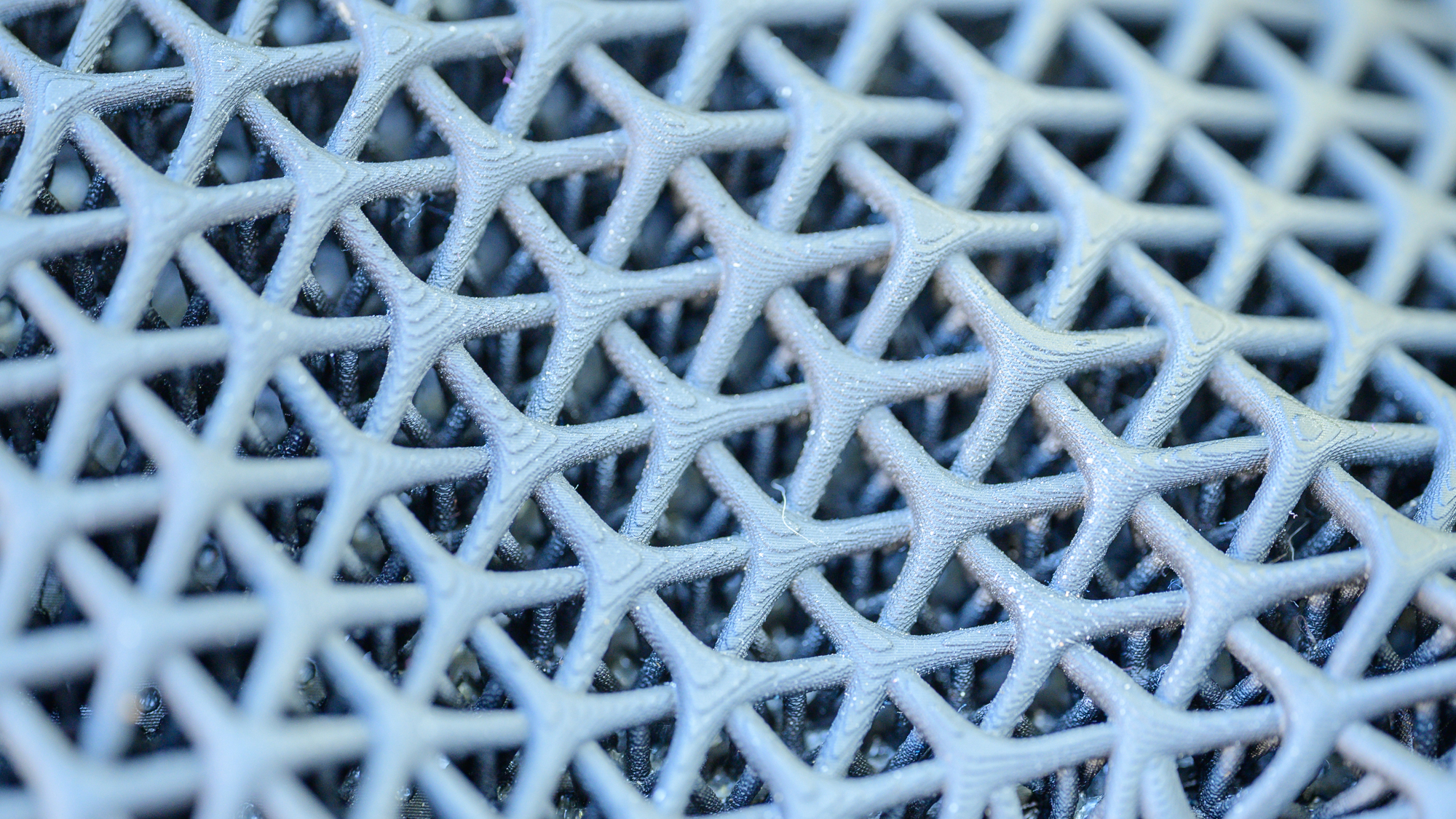

DLS differs from other 3D printing in a few important ways. Instead of laying down a layer of physical material, DLS starts by shining UV light through a dead zone at a liquid. As the light hits the liquid it causes a layer to form and the object moves away from the edge of the liquid leaving room for the next layer. Eventually, a finished part emerges from the liquid with minimal visible layering and no internal voids. The final step is heat curing which adds further strength. It seems to work well for saddles - it's recently debuted in helmet pads too - but, as mentioned, it’s not unique to Selle San Marco.

Instead of focusing on a new production process, the designers at Selle San Marco focused their efforts on building from a known quantity. That starts with the same shape as other Selle San Marco Shortfit 2.0 options which, in the smaller S3 version, starts with a 140 x 255 size. That length slots in between the two major competitors for 3D printed saddles, the 242mm Specialized Power and the 265mm Fizik Vento Argo. If you'd prefer a wider saddle, there's also the L3 option at 155mm wide and both the S3 and the L3 are available with carbon rails and less weight.

As you look beyond the dimensions, you'll find a slight wave to the Shortfit 2.0 3D. I warn you, it's slight so if you prefer a deep wave, you'll want to look elsewhere. Instead there is a pronounced rear kick then a slight dip and rise before a very slight descent begins and continues to the nose. In the centre of the saddle is a wide depression that starts in the rear kick then narrows slightly and continues as a teardrop shape almost all the way to the nose. The outer wings are steep and drop off quickly.

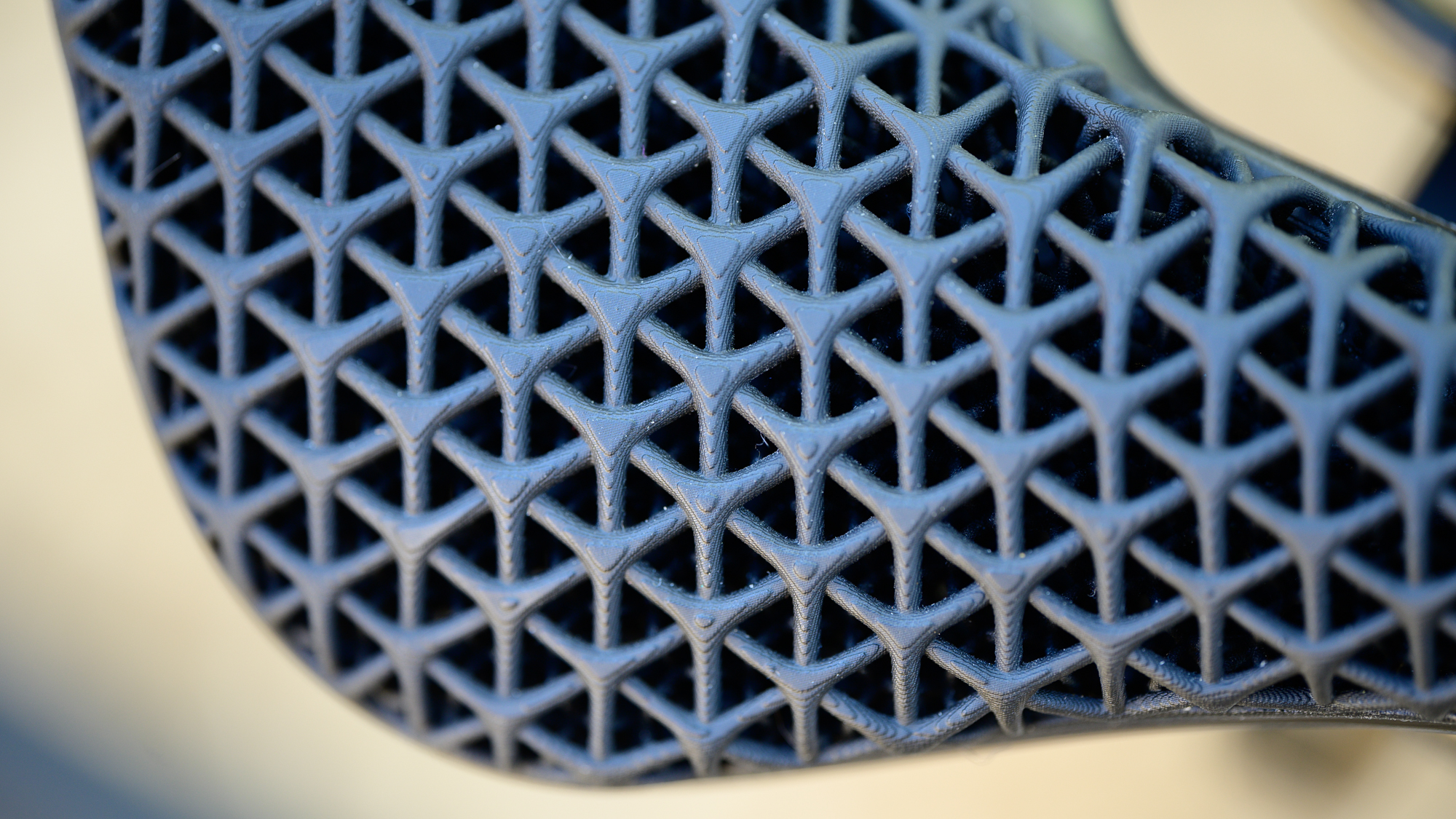

One place where the 3D printing is dominant is the aesthetics of the Selle San Marco Shortfit 2.0 3D. Specialized uses a rather closed outer in the Power Mirror and, while the first generation Fizik Antares Versus Evo is a bit more open, Fizik closed up the pattern further for the second generation Vento Argo. Selle San Marco eschews both with a much bolder design language that really shows off the 3D printing.

As you look at the padding, you will see a series of three pointed shapes. Depending on your perspective it's a series of triangles or starbursts. In either case though, it's very open and close examination shows off the layers created in the print. Even with the open nature of the matrix though, you can't see any light through it. Every section of the padding sits on top of a carbon reinforced nylon shell.

Performance

The very first time I got on the Specialized 3D printed saddle, I was in love. I wasn't necessarily in love with the shape but using 3D printing for the padding absolutely changes what is possible. The ability to vary the structure of the matrix very precisely allows a brand to tune softness vs stiffness in a way that's impossible with traditional foam. What you get, at least from Specialized, is a saddle that's much softer than you'd expect from a serious performance saddle.

The next opportunity I had to experience a 3D printed saddle was from Fizik. The Fizik Vento Argo Adaptive is a second generation product and Fizik was quick to point out the greater ability to finetune the padding. In the end the shape is again not my absolute favourite but good enough that I've also spent thousands of miles on that saddle. One thing I'm always telling people though is that Fizik didn't seem to take the same liberties with the capabilities of a 3D printer. The padding feels a lot more traditional though still quite good.

Now, after a few years, I've had the chance to spend time on the Selle San Marco Shortfit 2.0 3D Racing saddle in the S3 size and I'm in love. While I'm generally a fan of the shift to a shorter saddle shape, I'm not as big of a fan of the loss of narrow saddles. I'm not a big person and my hips are narrow so I constantly want the narrowest saddle option for testing.

While both Fizik and Selle San Marco quote a width of 140, the specs don't actually tell the story. The Shortfit 2.0 has a more pronounced wing design and the drop off is quick and steep on the wings. The result is that the section you actually sit on is around 60mm and roughly 30 mm narrower than the space on the Fizik.

Selle San Marco also seems to have really understood how to put 3D print technology to the best use with the padding. There's none of the unnecessary stiffness you'll find in traditional foam. The combination of a narrow front and large cutout for this saddle leaves you essentially balancing on long straight virtual tubes of padding. That along with the wave and the kick keep you in a fairly static spot when sitting. It could amount to torture but the sections are softer than you'd get with foam and there's even give that comes from the nylon shell. For me, it's perfect.

Verdict

A saddle is a personal preference and no saddle will be perfect for everyone. That doesn't change when talking about a 3D printed saddle. The only difference there is that 3D printing allows for much more precise tuning of the padding. A great saddle company can exploit this new tool to do what they've always done before just with more precision.

What that really means is that you need to start by forgetting about the 3D print technology. If you are a small person that prefers a narrow saddle then the Selle San Marco Shortfit 2.0 3D Racing saddle might be a good fit. You'll also need to be someone who prefers a little bit of a wave to help keep you in place while seated but like to stand with enough regularity that you appreciate a saddle that makes it easy. If that sounds good then take a look at the Selle San Marco Shortfit 2.0 and if you've got the extra money, the 3D printed version is softer without having to worry about chafing.

My one caveat though is that it's worth going for the carbon version. It's a big price jump to get the 3D printed version but a relatively small price jump to make it carbon. The stainless rails and nylon work fine but they don't visually match the quality of the upper. If you are willing to invest in the 3D printed upper, take it a bit farther and add the bling to match. It's also a bit lighter in carbon though it's still not a featherweight saddle.