Let's get what will for many be the talking point out of the way early; these titanium sunglasses are going to set you back £350/$400/EUR400. We can’t think of a set from a major brand that even comes close to that, even amongst the very best cycling glasses. That being said, none of them are 3D printed from titanium either, so it’s no great surprise that there’s a premium price tag.

Before we collectively baulk at the price tag, and the fact that these only have a saving of 1g - yes, a single gram - over the standard POC Elicit sunglasses, it’s worth remembering that they are a limited edition, so it’s probably best to see them as a proof of concept for now rather than something for mass production.

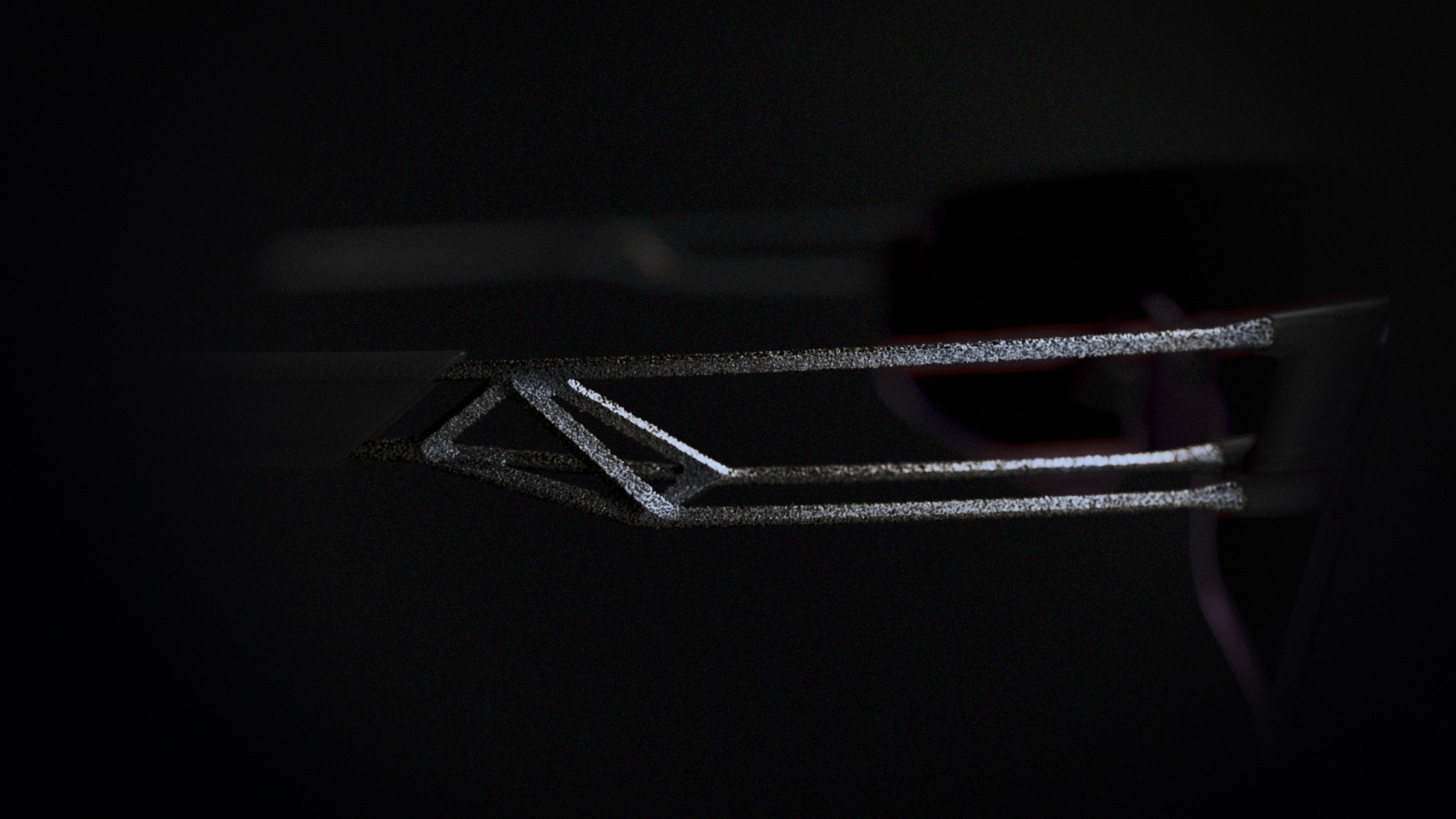

3D printed arms

The Elicit Ti is effectively the same construction as the standard POC Elicit sunglasses, a set of shades we rated extremely highly. The Clarity lens, interchangeable nose pieces, and the way the arms snap on and off the lenses for a lens swap are unchanged. The real difference is in the arms themselves. The already skeletal Elicit plastic arms have been replaced by a pair of truly emaciated titanium arms, each consisting of nine or so extremely thin filaments in a truss formation. The rubberised temple grippers are then slid over this skeleton to help grip.

Yes, titanium is an extremely stiff material, but like all things if you make it narrow enough it will flex (think glass in fibre optic cables for example). The filaments of the arms are diminutive enough to allow the arms to flex and grip the head in the same way plastic arms would. Given the limitations of 3D printing, there are no hinges on this model, so it’s either on your face or in the helmet vents for storage, or to pack away into a case you’ll have to remove the arms.

Reclaimed waste for a more sustainable production

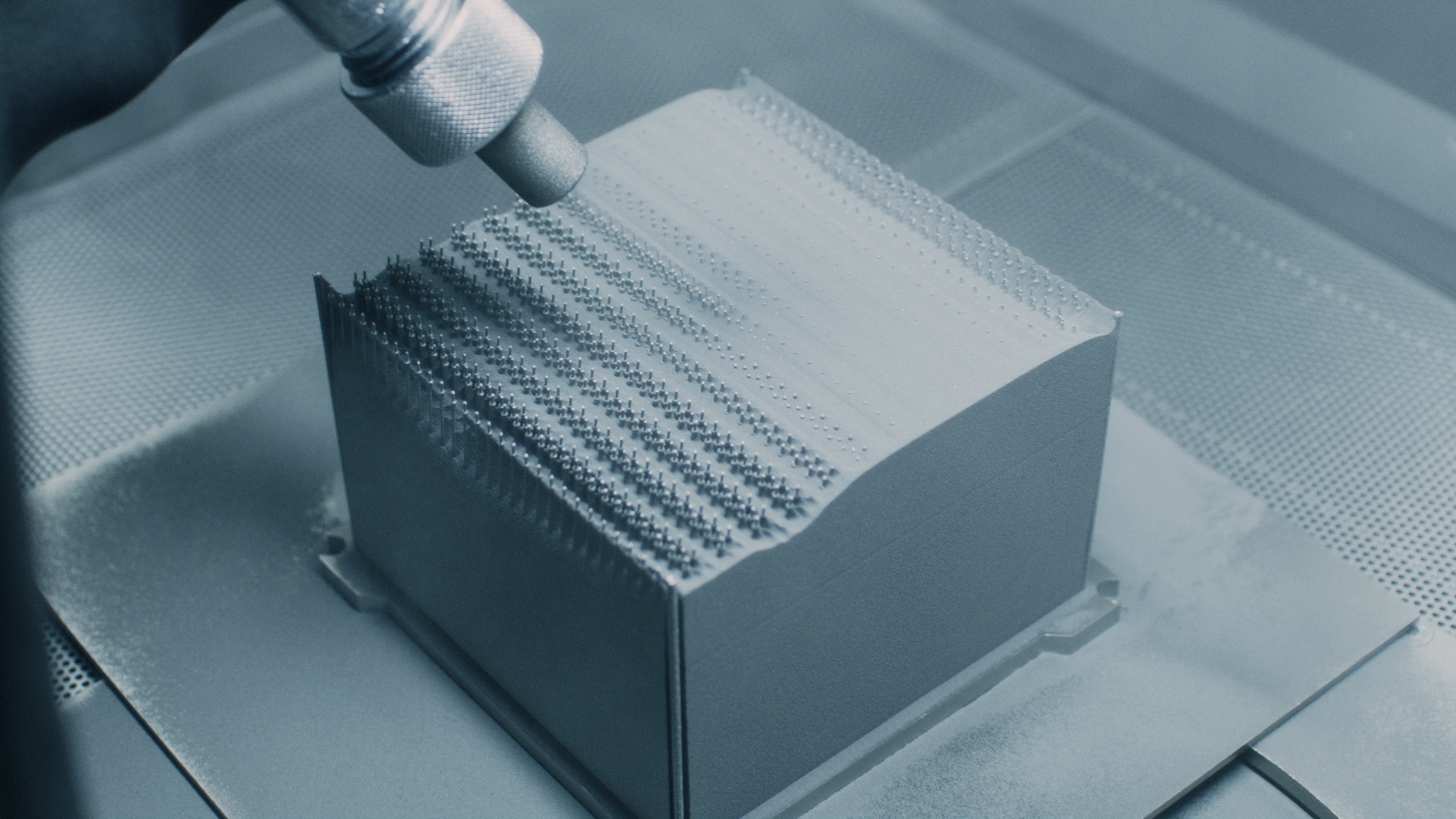

3D printing in titanium is a little different to doing so with composites. Given the melting point of Ti is over 1500 degrees Celsius you can’t extrude it into shapes. Instead, intricate shapes are built up in layers by locally melting a powdered alloy with a high-powered laser. After each layer has been melted a new film of powder is evenly distributed over the printing area and another layer is melted on. At the end of production you end up with a block of loosely amalgamated dust, within which resides the solid form of whatever you’re printing; blast it with air and you reveal the final form, or forms in the case of these arms, which are printed in batches.

Compared to using plastics it’s an expensive and time-consuming practice, but on the flip side, it comes with claimed improvements in sustainability. Tilda Håll, product manager for eyewear at POC says “...sustainable materials and performance can, and should, be able to live side by side. If we challenge conventional thinking and methods, there is no need to compromise performance or sustainability or a reason to choose one over another. Instead, it should be able to co-exist and become the norm. And we are proud that with the Elicit Ti we have shown just that.”

The details on the reclamation of the material itself are somewhat vague, with only the fact that the material is waste from the production of other medical tools in Sweden mentioned. We suspect that the waste powder from the production of medical-grade implements cannot be reused for the same such production, but can be reused for the production of cycling eyewear as they’re intended for external use only.

If you want to get your paws on a set they are available now in limited numbers. We’ve got a pair on the way to see how they shape up against the competition, and if you want to see them in action then tune into coverage of the Giro d’Italia, where the EF Education - EasyPost will be sporting them.