MESA, Ariz. — At the end of the line of pitching rubbers and home plates that make up the “12-pac” — a large outdoor bullpen at the Cubs’ spring-training complex — sits a triangular wooden structure supporting a rubber mat-clad wall.

Similar structures have become more common around baseball in recent years, as weighted PlyoCare ball programs, popularized by Driveline, have spread. But this mobile plyo wall came from the mind and hands of James Ogden, the Cubs’ minor-league coordinator of pitching performance.

“He’s a pitching coordinator, but he’s almost been working as a contractor,” Cubs vice president of player development Jared Banner said, laughing. “Over the last couple of months, I’ve gotten more sketches from him than I ever would have expected. But it’s that kind of desire to do whatever it takes to help the players that really stands out.”

Some pitchers just use plyo balls for warmups and maintaining strength and stability. For others, they’re a tool in velocity programs. And velocity training has been one of the development pillars the Cubs have leaned on to shake their poor track record with homegrown pitching.

This offseason, the Cubs put several major-league pitchers, including Rowan Wick, Adrian Sampson and Javier Assad, on plyo ball velocity programs.

The Cubs’ stationary plyo wall has been up for a few years, but it’s over behind the batting cages.

“Weighted balls are staples of a lot of guys’ programs,” Ogden said, “and we just wanted to make sure they had an easier way to get to them.”

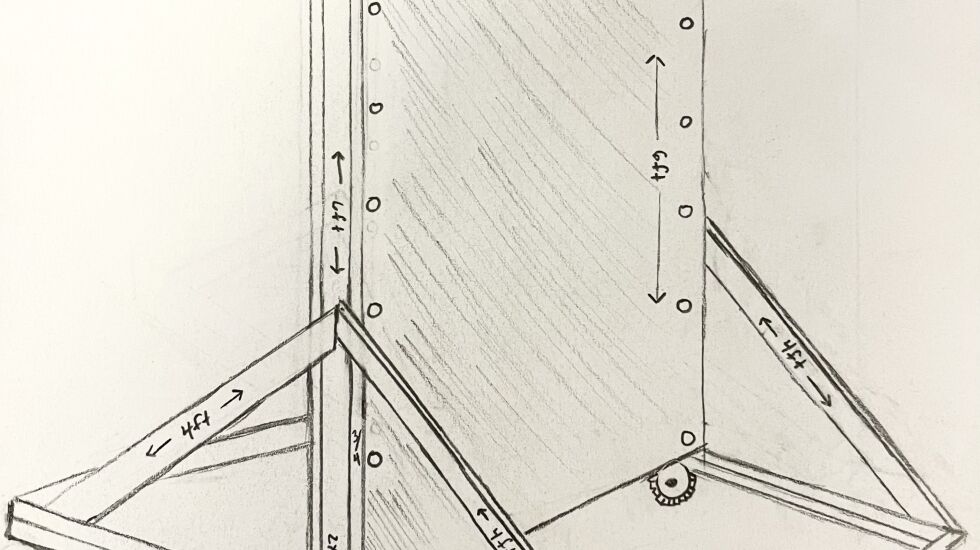

The sketches Ogden sent to Banner look like something from an architect’s desk — crisp straight lines and measurements jotted down in neat handwriting.

“It’s good to know if somebody’s house is in need of repairs or something, we’ve got a guy,” Cubs vice president of pitching Craig Breslow joked.

Ogden constructed strike zone string kits out of PVC pipe a year ago. Pitchers use them during side sessions for immediate feedback. Ogden designed them to be collapsible and portable so they can be taken on the road. The strings stretch from one pole to the other across the plate to outline sections of the strike zone.

“Taking it a step further,” Ogden said, “we actually dove into looking at where those dimensions are for the most swing-and-miss — top of the zone, bottom of the zone, etc.”

Some of the string systems, he said, have extra holes in the PVC pipe, remnants of that tinkering.

“The ideas are certainly not mine,” Ogden said of plyo walls and string systems. “The specific designs, I’ve maybe had some creative ideas to make it our own.”

Ogden, who’s in his fourth year as a Cubs pitching coordinator, doesn’t have an engineering background. He got his bachelor’s degree in oral communications with a minor in health, and he earned a master’s degree in education with an emphasis on instructional leadership.

But he always has been handy, constructing forts and tree houses as a kid — some more successful than others. His longest-lasting tree house was built out of pallets on his family’s property in Paducah, Kentucky.

“I’m definitely a legend in my own mind when it comes to fixing and building things,” Ogden said.

He attributes his ability to translating that hobby onto the field to his time in college baseball. Ogden spent seven years as the pitching coach at his alma mater, Lipscomb University in Nashville,

Tennessee. He has an Atlantic Sun conference title to show for it.

“Being in the college game a long time, you found ways to get things done without having to outsource them,” Ogden said.

So when he saw a need for mobile versions of the plyo wall, he got to sketching.

“We have the ability to customize [those tools] to our needs in-house, so it’s something we can and do take advantage of,” Breslow said. “Obviously, we want to make sure that doesn’t impact his ability to influence our players directly, but he’s spent some long nights here trying to prepare those things for us.”

A cursory Google search for “mobile plyo wall” turns up plenty of videos on how to build one at home. Some aren’t actually mobile and require digging holes to root the posts. Others are little more than a mat attached to a chain link fence.

It takes some sifting to find any designs similar to Ogden’s, which uses triangular supports, rising from a rectangular base, to hold up the two-sided wall in the middle. Six cart wheels make it mobile without forfeiting stability.

The product testing — a two-man operation; Ogden said he “conned” major-league pitching strategist Danny Hutzen into helping — had to answer two simple questions: 1. Does it hold together when things are thrown against it? 2. When you try to move it, does it roll?

Ogden went the extra mile with the details. On one side of the wall, nine sets of prongs protrude from the triangular supports, each supporting a different colored plyo ball, ordered by weight. On the other side, a trough holds a set of medicine balls. A core velocity belt hangs off the back.

How does a pitcher use such an apparatus? Look at lefty Drew Smyly’s routine before throwing his first live batting practice session last week.

He started with a medicine ball, rotating from a lunge position to heave it against the plyo wall. Then he moved to the other side, throwing a heavier plyo ball backward against the wall before grabbing something lighter for front-facing tosses.

“That was pretty neat,” he said. “It’s a pretty solid job.”

This season, each affiliate will have at least one mobile plyo wall, and Wrigley Field will have at least one, Ogden said. The Cubs just haven’t figured out yet how they’ll get them to each location.

“Worst-case scenario is I rent a truck and drive them to each one,” Ogden said, “or build them at the affiliates and then hope it works the same?”

Whatever method, it’s safe to say Ogden will find a way to get it done.