Pearson Engineering has secured a £25m contract to supply turrets for the British Army's Challenger 3 tanks.

The work will secure 285 jobs at the former Vickers factory in Newcastle, prompting a £4m investment in machinery and the recruitment of new technical roles as well as 20 apprentices.

Pearson will supply Washington-based Rheinmetall BAE Systems Land (RBSL), which has an £800m contract to upgrade 148 Challenger 3 tanks - described as Europe's most lethal.

Read more: Go-Ahead retains UK's largest rail contract despite "appalling breach of trust"

The turrets manufactured by Pearson will be versatile so they can be fitted to the tanks of allies and global partners.

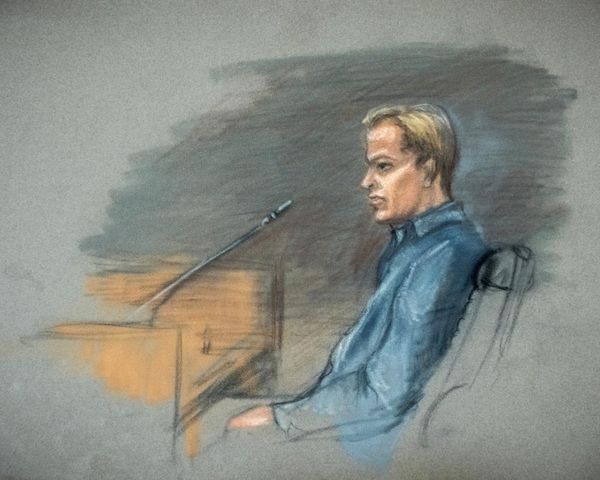

Minister for Defence Procurement Jeremy Quin attended a steel cutting ceremony at the Armstrong Works, along with Major General Simon Hamilton, British Army director programmes and representatives from DE&S, Army HQ, RBSL and Pearson Engineering.

The group received an update on the Challenger 3 programme and addressed members of the Pearson Engineering workforce at the historic Newcastle site, before cutting the first piece of steel for the Challenger 3 turret structures using a water-jet cutter.

Craig Priday, managing director for Pearson Engineering, said: “This important contract for Pearson Engineering, delivered together with our sister company Responsive Engineering, demonstrates our success in bringing armoured vehicle manufacturing back to the North East.

"Alongside our strong export business, this multi-year project utilises the world class capabilities of our team at Armstrong Works, and allows us to further invest in skills, jobs and the local economy. It has been a real pleasure to welcome key stakeholders here today for the steel cutting ceremony and we look forward to working with RBSL as the programme progresses.”

Brig Nick Cowey, Challenger 3 senior responsible owner, said: “I’m really excited at this key milestone in the Challenger 3 programme being achieved on schedule. The turret fabrication being conducted here by Pearson Engineering is crucial for the delivery of a fully digitised turret, ensuring that our modernised Main Battle Tank is the most lethal in Europe.”

Dr Marco Noeding, managing director for RBSL, said: “Today’s announcement marks the latest in a series of UK supplier contracts awarded by RBSL for Challenger 3, ensuring the programme benefits from the best of British engineering and manufacturing whilst also sustaining valuable skills across the country. The steel cutting ceremony in particular has been an excellent opportunity to commemorate a special milestone alongside our customer and new partner. Welcome to the team, Pearson Engineering.”

The Minister for Defence Procurement used his visit to the North East to also open the first defence science and technology hub, based at the National Innovation Centre for Data on Newcastle's Helix site.

The Dstl science and technology hub - which aims to achieve full operating capability in spring 2023, employing 15 people - will carry out AI and data science related research to help defence, turn data into information advantage, and to accelerate the responsible and ethical adoption of AI across defence.

Dr Paul Hollinshead, chief executive of Dstl, said: "This is a really exciting time for Dstl and our drive to support UK science and technology. The hub already has seven members of staff working at The Catalyst building, and we look forward to harnessing further talent from across the region to deliver the best scientific advice and solutions to the MOD and the country."