There’s a newly-devised chemical composition that could make OLED panels more eco-friendly and cheaper to make by excluding highly expensive rare earth materials that, for years, have gone into the best OLED TVs.

The key to the breakthrough is a brand-new manganese (Mn) complex developed by the Dongguk University. The South Korea-based university published its findings in the Chemical Engineering Journal this past October, highlighting a breakthrough method in the fabrication process of OLED substrates.

Most OLED displays are made using a so-called solution-process, which requires expensive rare earth materials to maintain stability and efficiency in their internal complexes. Several other constraints, like solvent resistivity, as outlined by a paper published in the National Institutes of Health, prove that the solution process isn’t a full-proof or cost-effective method to OLED fabrication.

The approach conducted by researchers at Dongguk University, however, leverages far more abundant and cheaper materials over the conventional manufacturing process.

The groundbreaking science of OLED TV tech

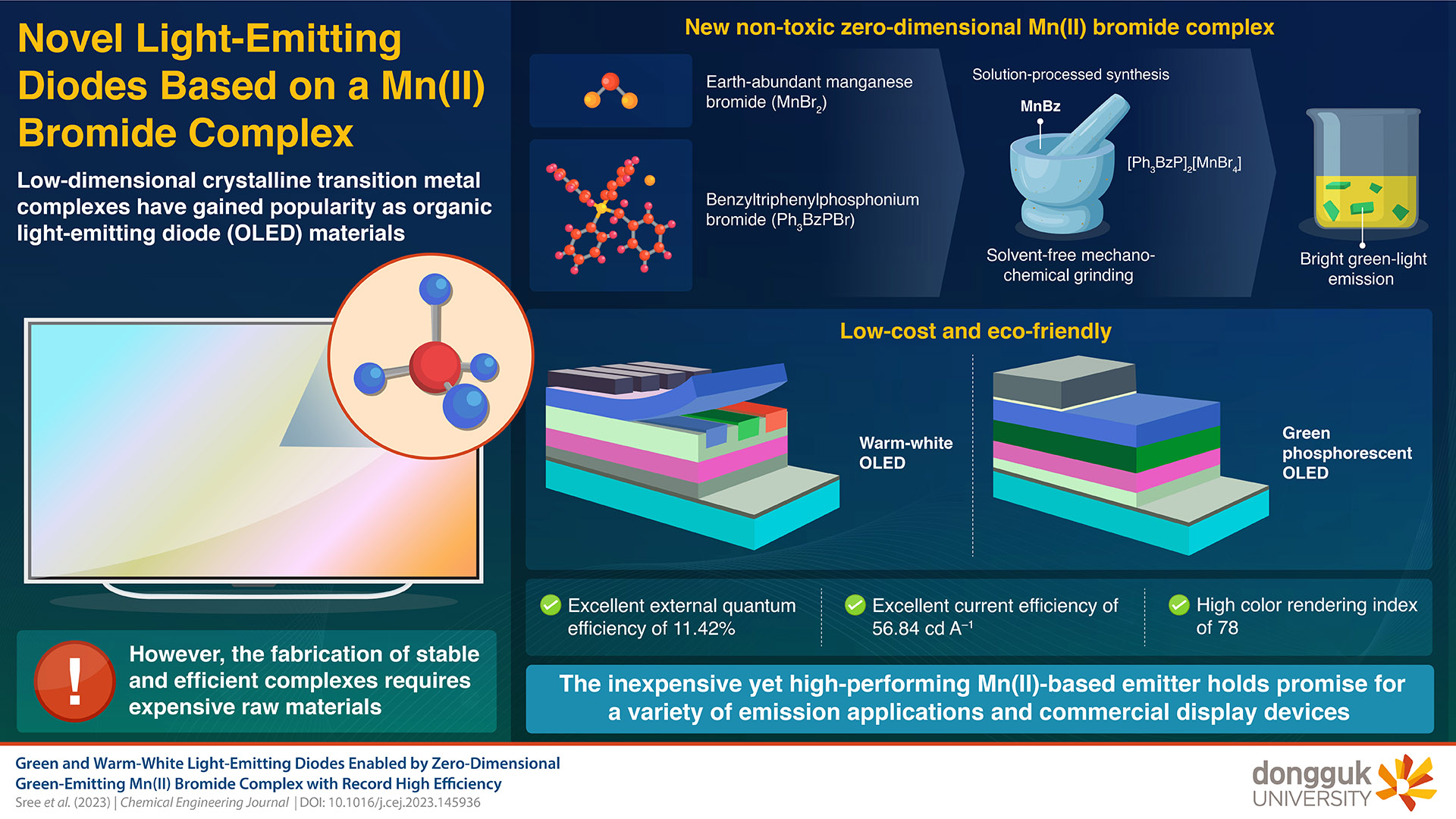

The team, led by Assistant Professor Vijaya Gopalan Sree, discovered through a novel process an all-new non-toxic zero-dimensional Mn(II) bromide complex (MnBz) that could reshape the way OLED emitters are handled amid fabrication.

Their process saw the synthetization of MnBz by combining two chemicals — manganese bromide (MnBr2) and benzyltriphenylphosphonium (Ph3BzPBr) — through solvent-free grinding. The newly created solution was thus evaporated over the course of several days, resulting in single MnBz crystals, which proved to show a high quantum yield in tandem with bright green-light emissions.

Using these MnBz crystals, Sree and the team developed a warm-white light-emitting device and a green phosphorescent OLED device, both of which showed a current efficiency of 56.84 cd A-1 and a record-breaking quantum efficiency of 11.42%. In short, that’s far more efficient than current-generation OLEDs and reduces the ecological footprint of OLED manufacturing.

Additionally, the first of its kind complex-based warm-white light-emitting device delivered a color rendering index (CRI) of 78, which is quite good against conventional OLEDs that typically average around 90 and decrease over usage time.

“Replacing expensive rare earth metals like gold and platinum with crystalline earth-abundant transition metal complexes can help achieve lighting solutions or displays that are cheaper yet bright and vibrant,” explains Dr. Sree.

via Dongguk University.

Beyond potentially decreasing the average price for an OLED panel, the newly devised MnBz fabrication process could also ensure that such devices are energy-efficient. This is due largely to the high brightness specs of these MnBz-based emitters, as it could allow for more eco-friendly lighting systems and consumer electronics long-term.

So what does this mean for QD-OLED and LG OLED TVs?

LG’s OLED TVs, like the LG C3 OLED and LG G3 OLED, use the solution-process manufacturing technique. Similarly, for its QD-OLED TVs, like the S95C OLED, Samsung also leverages the solution process, which gives the firm’s models their higher pricing.

The switch to MnBz crystals could not only spell a more eco-friendly future for a wide variety of TV panels and assorted consumer electronics across firms, but also make them more affordable for the average consumer.

Can’t wait for these innovations to come down the road? If you’re looking for a cutting-edge OLED TV from LG, check out the LG C3 OLED, one of the best TVs of 2023.