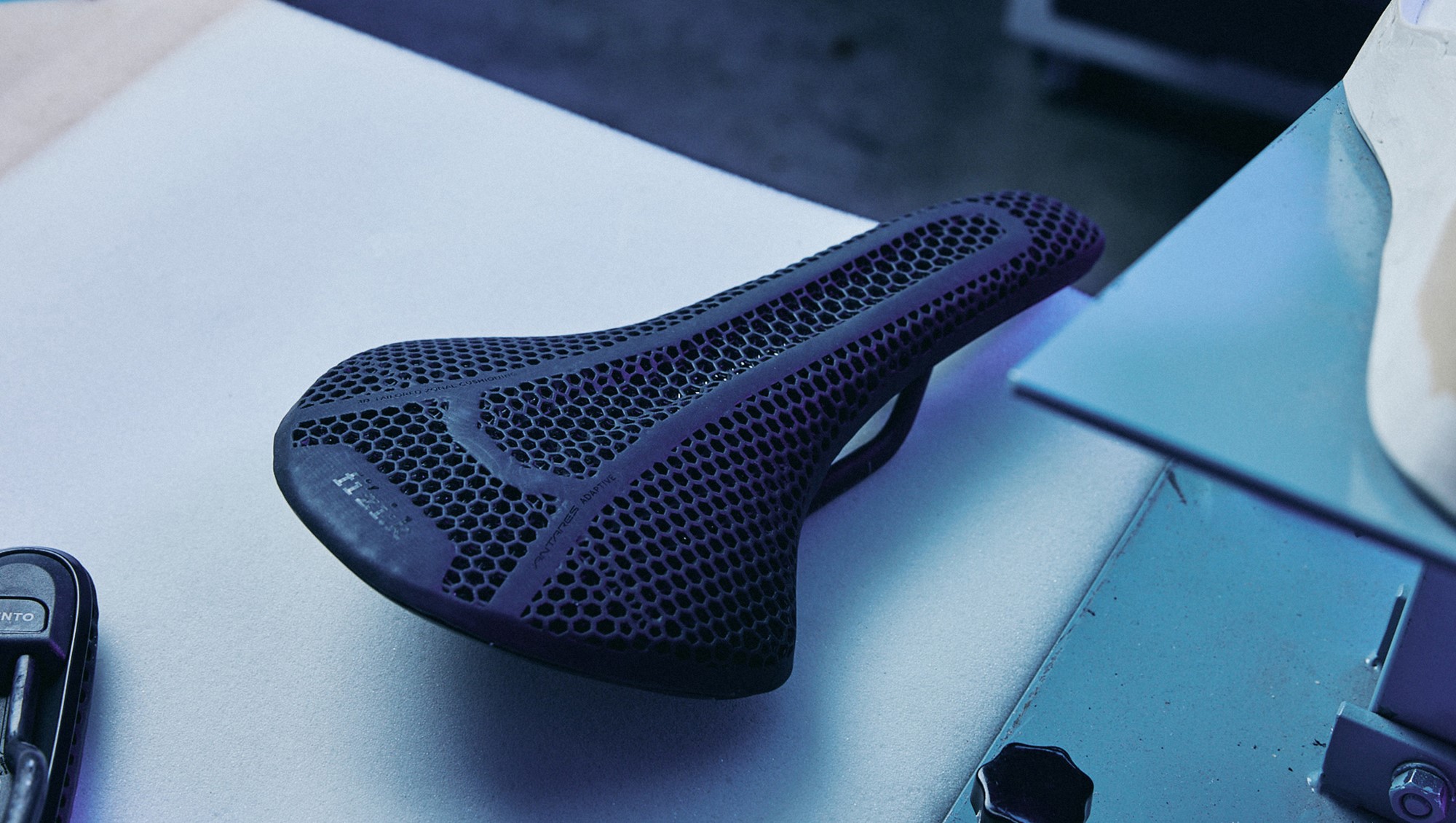

Fikik has launched a new service called One-to-One, which custom 3D prints one of its Adaptive saddle models to perfectly fit you. It’s available on a range of saddle bases with either carbon or Kium alloy rails.

Many riders find even the best bike saddles difficult to get comfortable with. While a bike fit can sort out many sources of discomfort and cycling injuries, and suggest a new saddle for you, until now you’ve been limited to what’s ready-made on the market. You’re going to be sitting on your saddle for hours on end, so getting it right can be vital.

The new One-to-One service looks to address this by providing a saddle that’s custom 3D-printed to match your anatomy, bike set-up, riding position and the type of riding you do, whether that’s on the road, on gravel, mountain biking or time trialling.

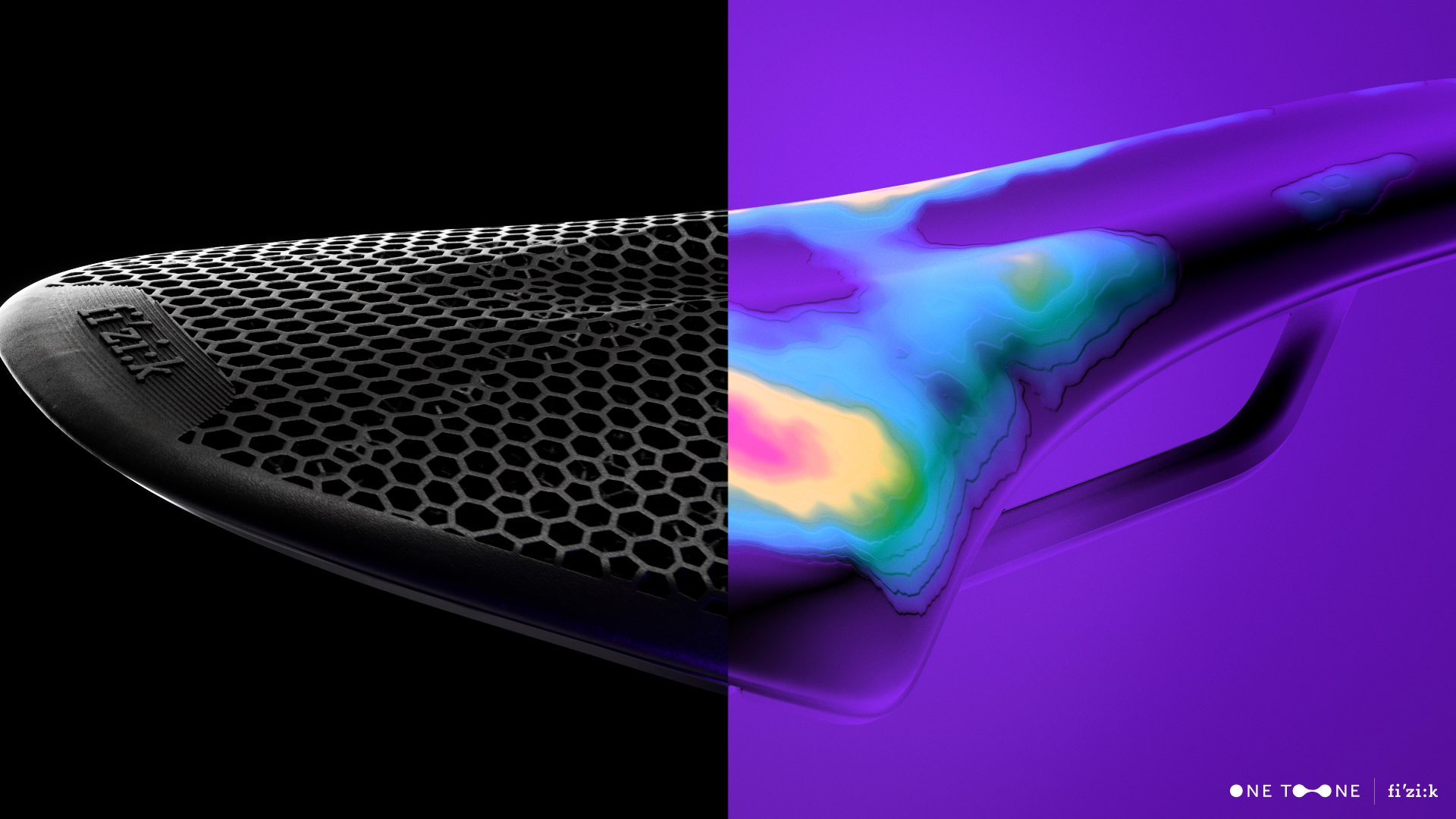

One-to-One uses one of Fizik’s existing Adaptive 3D-printed saddle models as a starting point, then forms a top surface to meet your individual needs.

Here’s how it works:

First up, a Fizik dealer equipped with the One-to-One system will complete a quick questionnaire and pressure map your current saddle across the full range of ride positions while riding your bike on a Wahoo Kickr Rollr trainer. This will allow them to choose the most compatible non-custom Adaptive saddle shape for you and your ride style.

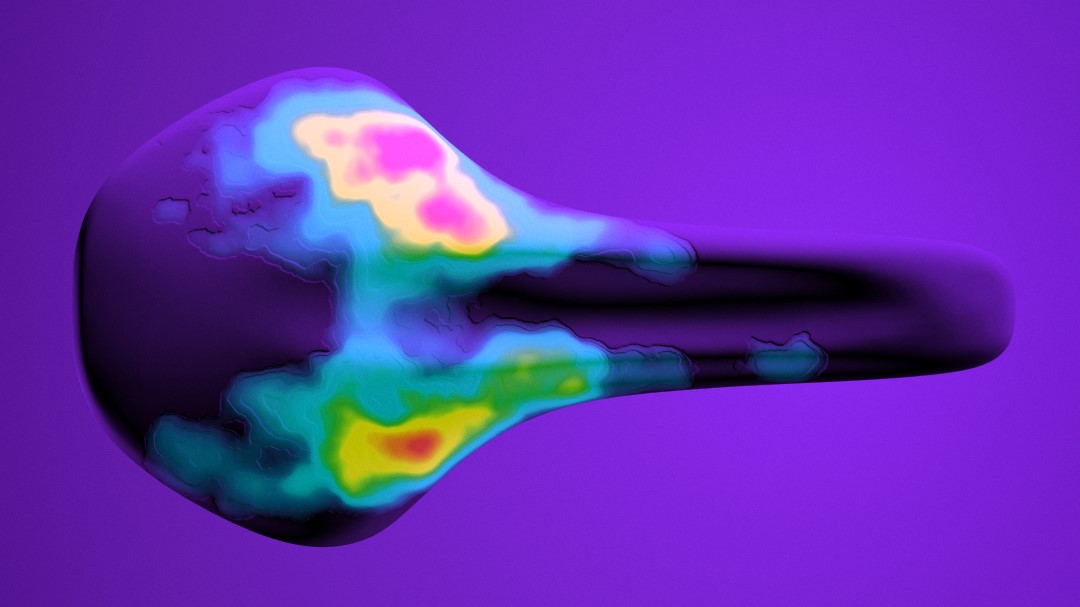

They’ll mount this saddle on your bike and then use pressure mapping to see how you interact with the saddle across 64 touchpoints in a range of positions, allowing them to identify your pelvic tilt, as well as asymmetries, instability and pressure hotspots.

Fizik uses the saddle pressure mapping system developed by gebioMized, which it says is the system most widely used by professional bike fitters. It’s worked with the company to research and test its system, and says has taken three years to develop.

The One-to-One service then automates the analysis of the data to design the 3D printed saddle top surface structure to best match your needs. You choose between carbon or Kium rails, then Fizik will produce your unique saddle and ship it to you.

You can later go back to the dealer to see how the new pressure distribution compares to your initial saddle fit.

3D printing has the advantage over traditional manufacturing techniques that it can be used to manufacture one-off pieces, whereas producing a standard padded saddle requires the use of mass-manufacturing techniques with a high volume of standardised parts.

It's already found its way into chamois pads and helmets, as well as a range of other components and even complete bike frames.

Saddle options and prices

Fizik Adaptive saddles available in the service are the Vento Argo, Terra Argo, Vento Antares, Tempo Aliante, Transiro Aeris LD and Transiro Aeris SD, with all but the Transiro triathlon saddles available in two widths. Fizik offers the service for its R3 Adaptive saddles with Kium rails or higher spec R1 saddles on carbon rails.

The service is available for an additional cost on top of the standard price for the Adaptive saddle model chosen. That puts the starting price for a One-to-One R3 Adaptive saddle on Kium rails at £459 / $499 / €459, with the R1 carbon rail saddles priced at £499 / $599 / €499.