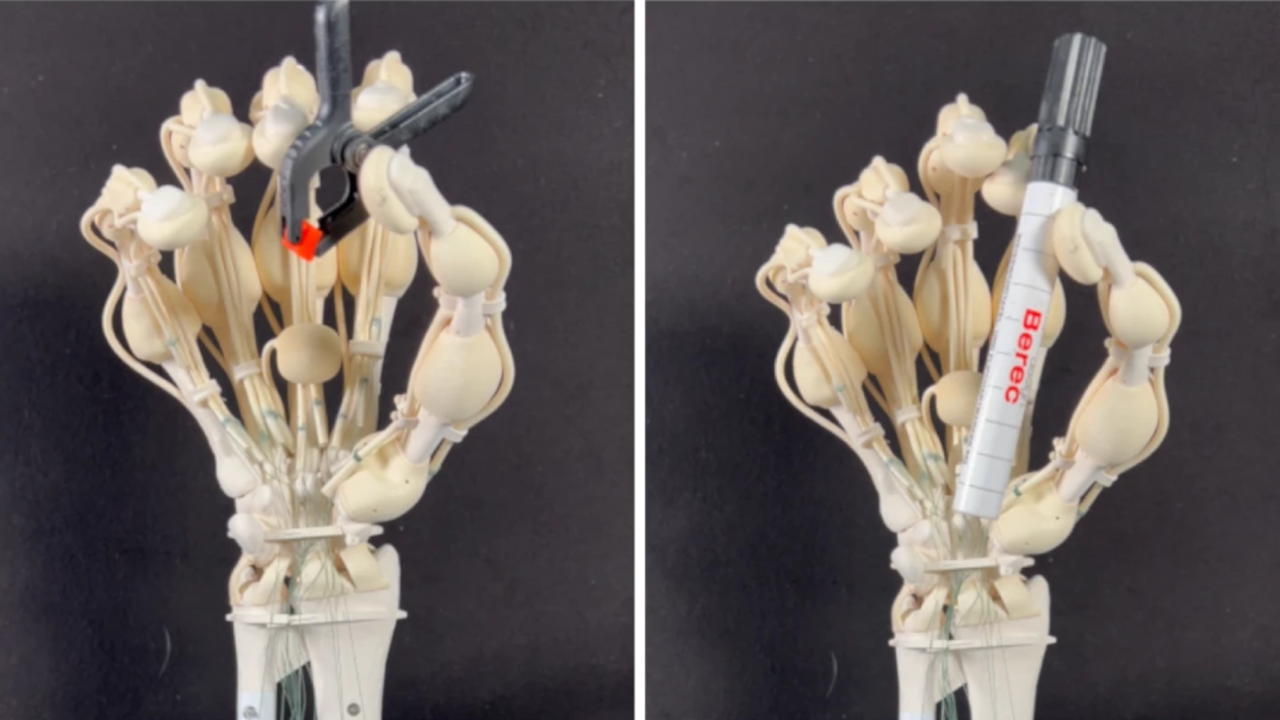

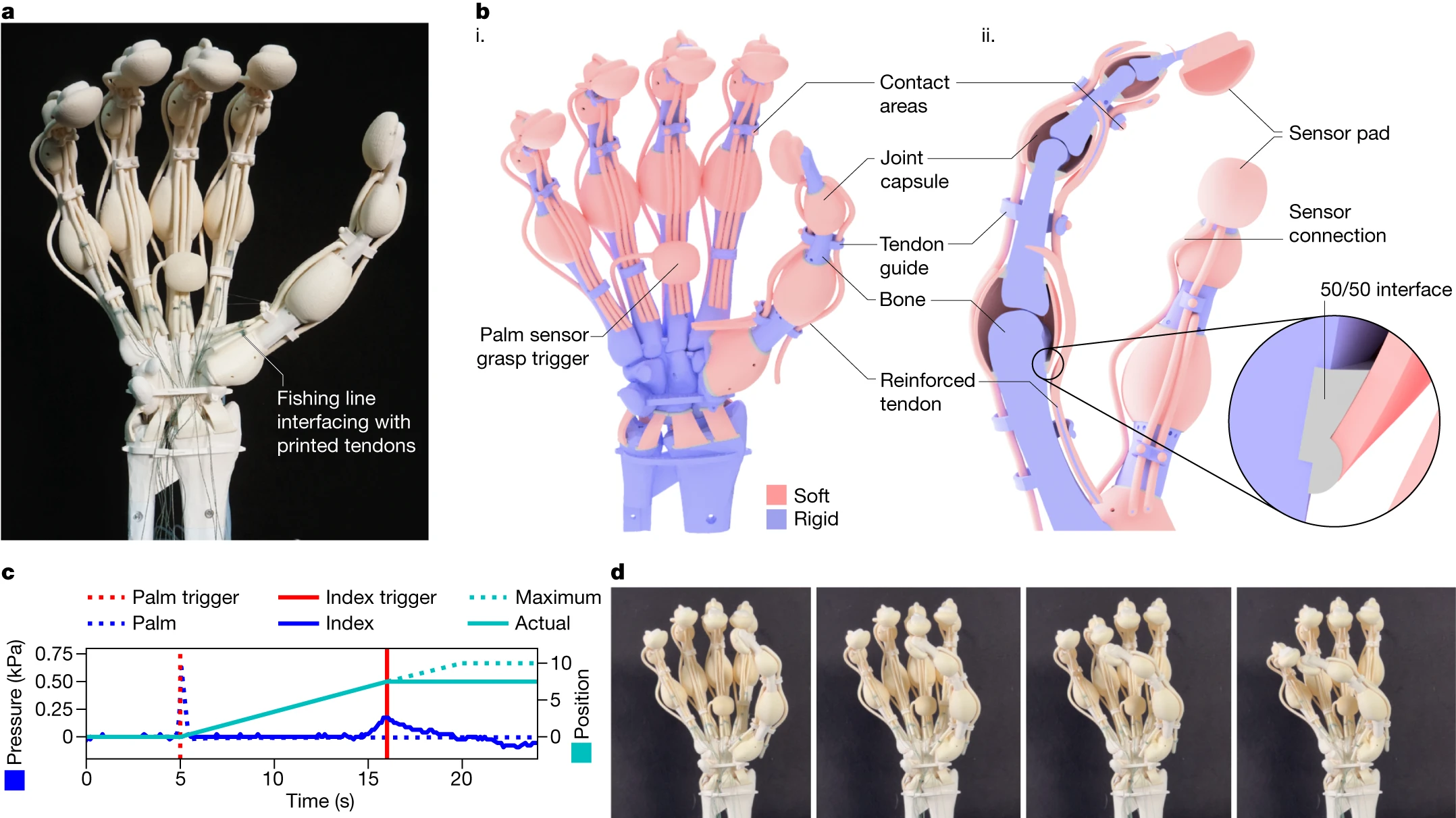

Researchers from Inkbit have leveraged their vision-controlled jetting (VCJ) 3D printing technology to print a functioning robotic hand in a single run. IEEE Spectrum covered this story but stemmed from Inkbit's own Nature article covering VCJ and its applications in exhaustive detail, with the hand being only one of many examples used.

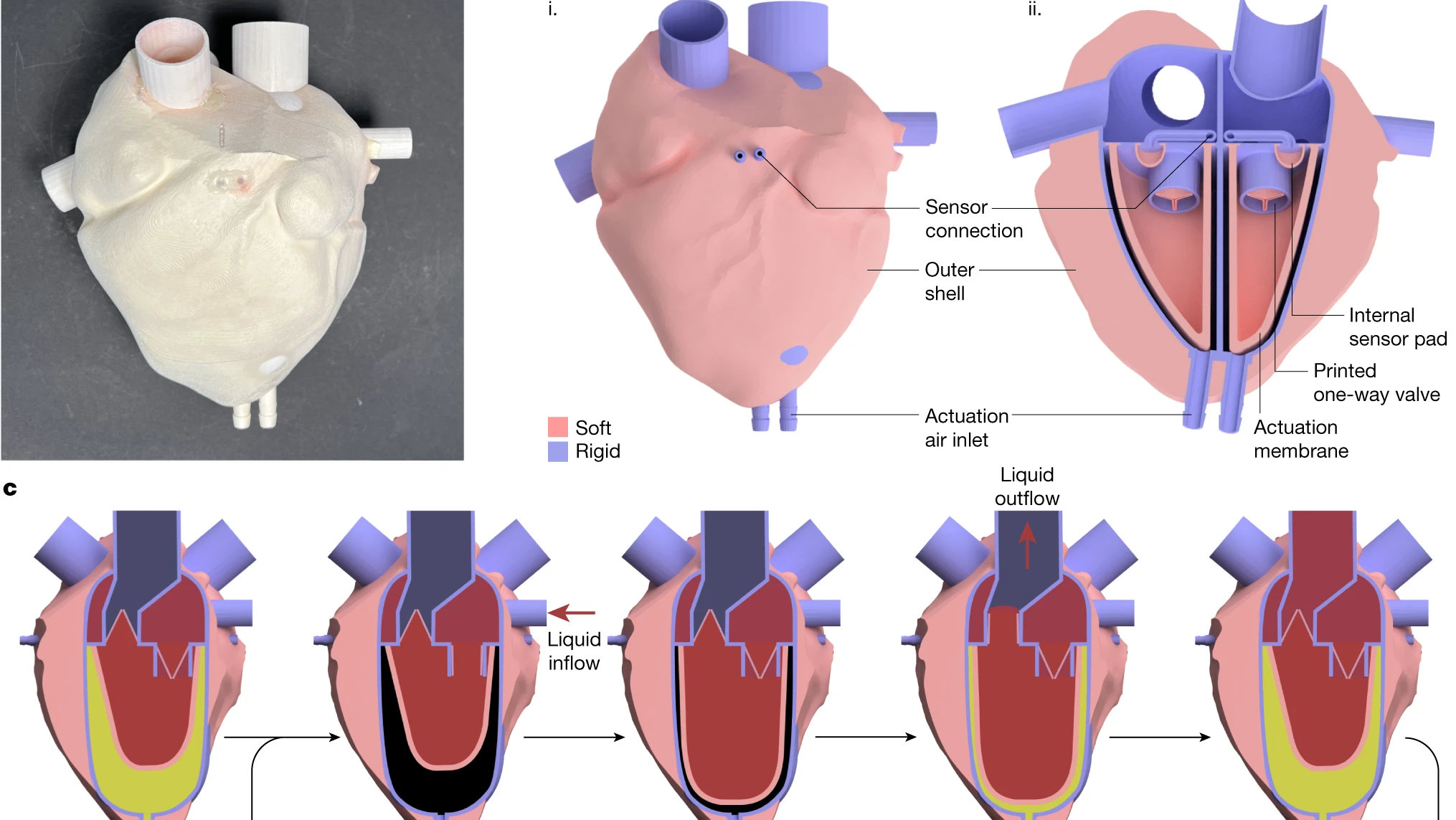

So, what makes VCJ a big deal compared to the best 3D printers with traditional 3D printing methods? Let's break it down. By using a 3D vision scanner alongside an inkjet unit and a UV-curing unit, VCJ allows for precise layer-by-layer jetting-and-curing of multiple 3D printing materials. This means that soft and rigid materials can be printed simultaneously, and the 3D vision scanner ensures per-layer corrections can be made without needing direct contact with the construct.

Besides a robotic hand, Inkjet showed other examples of its VCJ 3D printing method. These include a six-legged robot with a gripper for a "head" and even a robotic heart pump. Additional sensors are still required for these constructs to function. Still, the ability to fabricate such complex objects in a single go while using soft and rigid materials simultaneously marks a significant shift in what's possible with 3D printing.

So, what are the potential uses for all of this? According to Robert Katschmann, a robotics professor at ETH Zurich, speaking to IEEE Spectrum, current 3D printing materials usable by this method are limited to ones that can be cured with UV light and aren't too dense for the inkjet. However, this could still lead to using materials that allow for the 3D printing of electronic circuits and even human-compatible tissue engineering.

As always, time will determine whether or not this is the 3D printing breakthrough needed to push the field into realms only previously seen in science fiction. But if the current video demonstrations with the original article are any indication, this fabrication tech might be the next big step we need.