This article is about a small group of passionate people attempting to make the best cycling shoes in the world. I didn't know that when I started though. When I started down this path, I thought I'd be working on something about how a large brand like Specialized, which often shows up on our list of the best cycling shoes, actually makes shoes. Something along the lines of a factory tour but given the factory isn't in the USA (it's in China), probably more of a deep dive on process. I also thought I'd be going to Morgan Hill in California, and even as I booked my tickets to Colorado, I didn't think anything was going to change.

As I left my hotel under the kind of perfect blue sky you only see in late autumn at high altitude, I'll be honest and say I didn't have much of a plan. I knew I'd be meeting a few people but I had no idea where I was going or really even where I was. I was roughly 30-minutes outside Boulder in a town called Louisville but that wasn't giving me much of a clue. It was only as I pulled into the parking of a very familiar building that I got the sense of where I was.

In a rather nondescript office park I pulled into a spot in front of an award winning building. It wasn't the awards that I remembered though. I remembered that building because of Lael Wilcox. Back in 2019, when Wilcox had sponsorship with a different brand, she rode 650 miles from this building to the start of Unbound XL where she came in 2-hours ahead of the second place finisher. Since then, both Wilcox and the building have moved on and that morning there was a Specialized logo on the side of the building.

Given that the whole thing is a bit of a sore subject in certain circles, not least because the news of Specialized buying it came the same day it laid off 8% of its workforce, I didn't expect I'd talk about it. I only have a picture because I was playing with the camera on my new Google Pixel 8 Pro phone, and I grabbed a snapshot for a friend. Obviously things have shifted a bit so let's dive in.

The building isn't really moved into yet, and soon, I'm told, it will be known as the Specialized Boulder Innovation Center, but there are always going to be some who remember the association with Pearl Izumi. It's a fact that plays into the idea many have about Specialized as a brand.

Specialized is huge right? A faceless corporation that bowls over the little guys, though Pearl Izumi is hardly the little guy, and pushes out generic products... right? If you believe that, you probably also don't think much of the people who work for the brand. Let's be very clear though, that's not the reality.

Even the biggest brands in cycling, and Specialized is certainly a big name, are not very big. Cycling is a small part of the larger ecosystem of sports. Specialized has history and name recognition but it’s still small groups of passionate people designing cool products because they love them.

That day in Colorado, I sat down with eight people who make up the bulk of the team that brings you Specialized cycling shoes. It was an opportunity to talk to them about how Specialized brings you shoes but, as I’ve mentioned, it was also an opportunity to learn about how much passion there is for cycling and creating incredible products.

What I didn’t do much of that day was take pictures or go on tours. The building is still mostly empty. Old signs haven’t been changed and rooms lie empty. I was there as a guest of Nick Gosseen. Gosseen is the Business Unit Leader for Shoes, Saddles, BodyGeometry and Retül but he’s also the site leader for the new building and he’s got his hands full getting things set up. The one room that I did tour was the rapid prototyping room.

The rapid prototyping room is the domain of Kris Lovett. Lovett is an industrial designer by trade, but he’s also a crafter. His room is filled with laser cutters, multiple 3D printing machines, rolls of Dyneema fabric, and generally everything you need so that you can quickly mock up a new shoe. Sometimes existing base plates get new uppers and sometimes existing shoes get heavily modified. Either way though, the basic loop is back and forth between the room next door where an athlete can test the change in real time. That room is still empty though and I’m getting ahead of myself anyway.

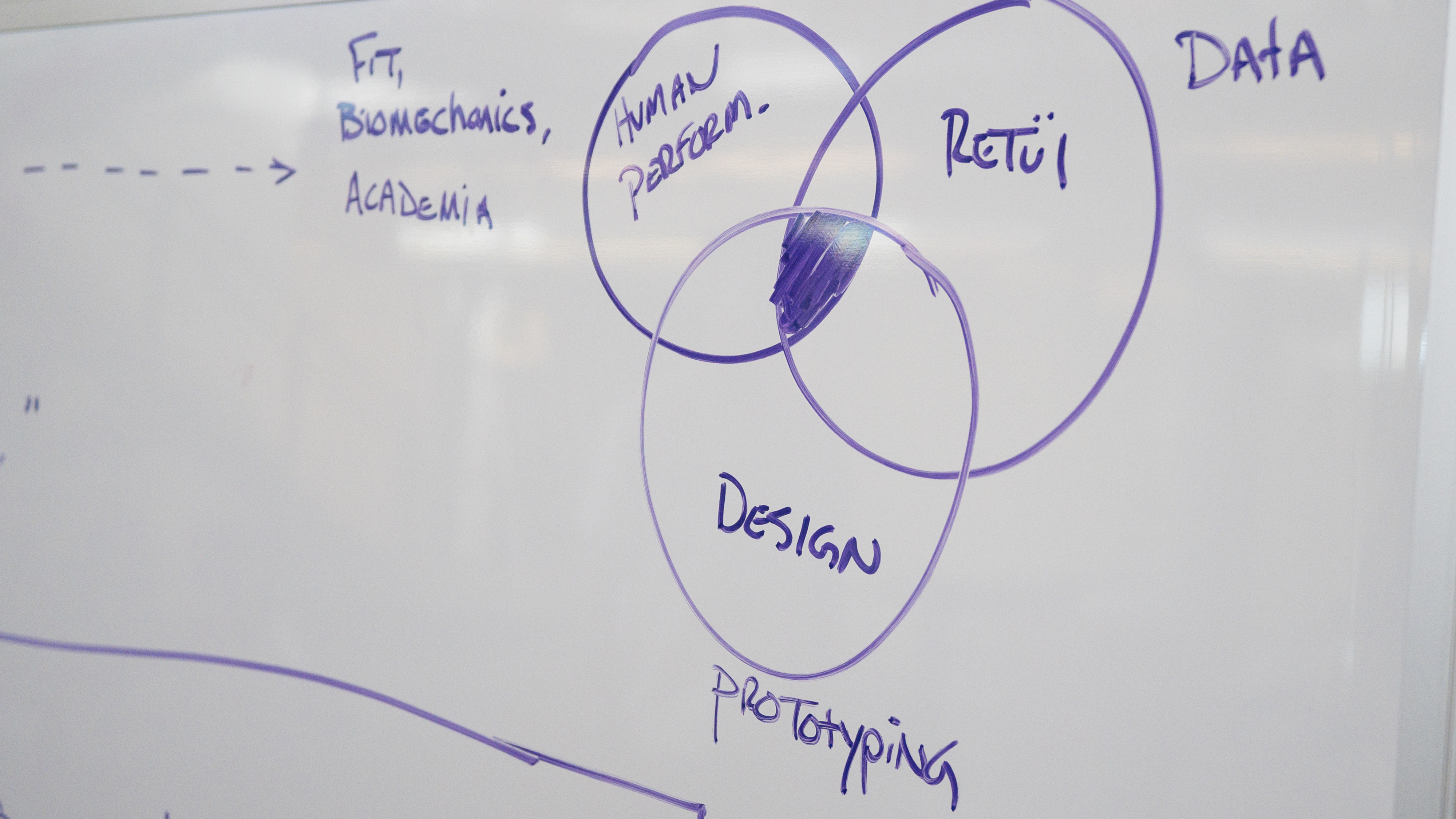

I sat down at a conference table in the middle of an empty building and I started by asking everyone who they were, what they did, and what kind of riding they did. I was sitting with Design Director for footwear and softgoods Rob Cook, Product Developer Ashley Sult, Fit and Wear Test Coordinator Jay Steuwe, Product Manager Tom Smith (who specifically mentioned that was not an alias), Todd Carver who is both Head of Human Performance and founder of Retül, and Product Manager Danielle Audino. Gosseen was also there helping facilitate the discussion. Between the group there was over 40 years of employment at Specialized. Only Audino was new but only if you count the time since she’d returned from the Marines. She had another year and a half before that as well.

Audino also had the experience of education. Both Audino and Steuwe have masters degrees in Sports Product Management from the University of Oregon. If you are unfamiliar, that’s a specialised degree with a focus on exactly the types of project management that Audino now handles for both the shoes and BodyGeometry teams at Specialized. Audino was also quite adept at going deep into how her status as an outsider in mountain biking meant that there was no question she wasn’t willing to ask.

That’s important because, asking questions is the crux of what the whole team is really about. They are all passionate cyclists, mostly road and gravel and likely faster than me, but they are also problem solvers. While we talked specifically about processes, I’m always quite interested to understand how production affects design, the bulk of what I heard was that this team cares about finding solutions.

I attempted to explore a process I thought would start and end with each shoe. That’s not what happens though. Instead, the process starts by identifying a need. Sometimes that need comes from an athlete, sometimes a reviewer, and sometimes from everyday riders. Yes, the team does read the comments and your thought might actually lead to change.

There’s also Retül and one of the largest databases of foot scans in the world which may generate a need. Wherever it comes from though, it’s the spark and it’s worth repeating that the start of the process is not business driven.

Each new shoe is a culmination of 800-1200 hours of testing and years of work by a highly experienced team but it’s also a snapshot. It is a frozen moment in time taken from a constantly shifting and moving bank of research and solutions that happens to match up with business and market needs for a short period. The rest of the time things operate more like an industrial design agency with a research firm.

Wherever the spark comes from, the team starts by refining what the question is. When there’s a very clear question the next step is to generate a hypothesis that might be the answer. Once there’s a clearly defined hypothesis then they use prototyping and research into performance and sports medicine to try and validate an answer. The end of that process is not a new shoe. Instead, it’s an answer.

You can think of that answer as then going into a database and there’s another parallel process going on that might generate shoes. As the answers build, parts of the team puts them against business tests. This is afterall a business so someone has to decide how much it will cost to incorporate those solutions into a finished shoe and if there’s a valid market need for enough people. If everything continues to check out then the focus shifts to actually producing a shoe and the realities of working with a factory and producing things at scale.

Let's also not forget that this is fashion; Cook passionately talked about how different silhouettes have different personalities and small changes set expectations. Remember though, the background process of solving problems never stops.

As I listened to everyone talk about their piece of the puzzle I couldn’t help but find myself inspired. Many on the team had spent time in my hometown of Portland, Oregon and we had some shared memories of locations.

Smith could claim a win at a local race that I certainly never had a shot at winning and I laughed with Steuwe about personalities in different parts of the city. We also talked about what was coming.

As Specialized continues to solve problems, it’s looking like the future might start to mirror the trends in wheels and tyres. I heard a lot about how comfort was the focus and how the team believes that making athletes more comfortable makes them faster.

We also talked about Cook finishing the 3 Peaks Cyclocross Race and I got my foot measured and inspected by Sult just like a WorldTour rider. Turns out I should be in a half size bigger shoe and I have collapsed arches.

As I walked back out and took another look at the building under that perfect blue sky, things looked different than when I’d walked in. The building didn’t really hold the same memories. Instead, the blue sky seemed to hold promise. I wanted to listen to good music and have big adventures with good friends.

The designs that Specialized puts out aren’t perfect for everyone. For example, I don't like that the S3 Boa dials can't pop open like the more widely used Li2. Now I know the people behind that decision though. I know they care about cycling and performance and that dial is a very specific decision. More than anything, I want to see if I can push hard enough for this team to solve a problem for me.