If there's one topic that's guaranteed to cause a heated discussion amongst PC enthusiasts, it's thermal paste. From how much to use, to what shape you apply, everyone has their own opinion on what's right and wrong. A team of material engineers in Texas reckon they have the best answer as to what paste is best, though, and it's a new liquid metal colloid.

Your average thermal paste is a colloid—a liquid with solid particles in suspension—with tiny grains of aluminium oxide and/or zinc oxide being mixed into silicone. It's perfectly decent stuff and unless you're really into overclocking, you don't need anything else. However, in recent years, so-called liquid metal has become the favoured option for high-end cooling.

As the name suggests, the material is a metal alloy, typically a eutectic mixture of gallium, indium, and tin (GaInSn, often sold under the brand name Galinstan). Some liquid metal compounds are even colloids, with microscopic copper grains added for that extra oomph, in terms of ultra-low thermal resistance.

However, a team of material scientists and engineers at the University of Texas has developed a new compound to beat them all (via Tom's Hardware). This liquid metal colloid is a mixture of the same GaInSn alloy (though other gallium alloys work too) and aluminium nitride particles.

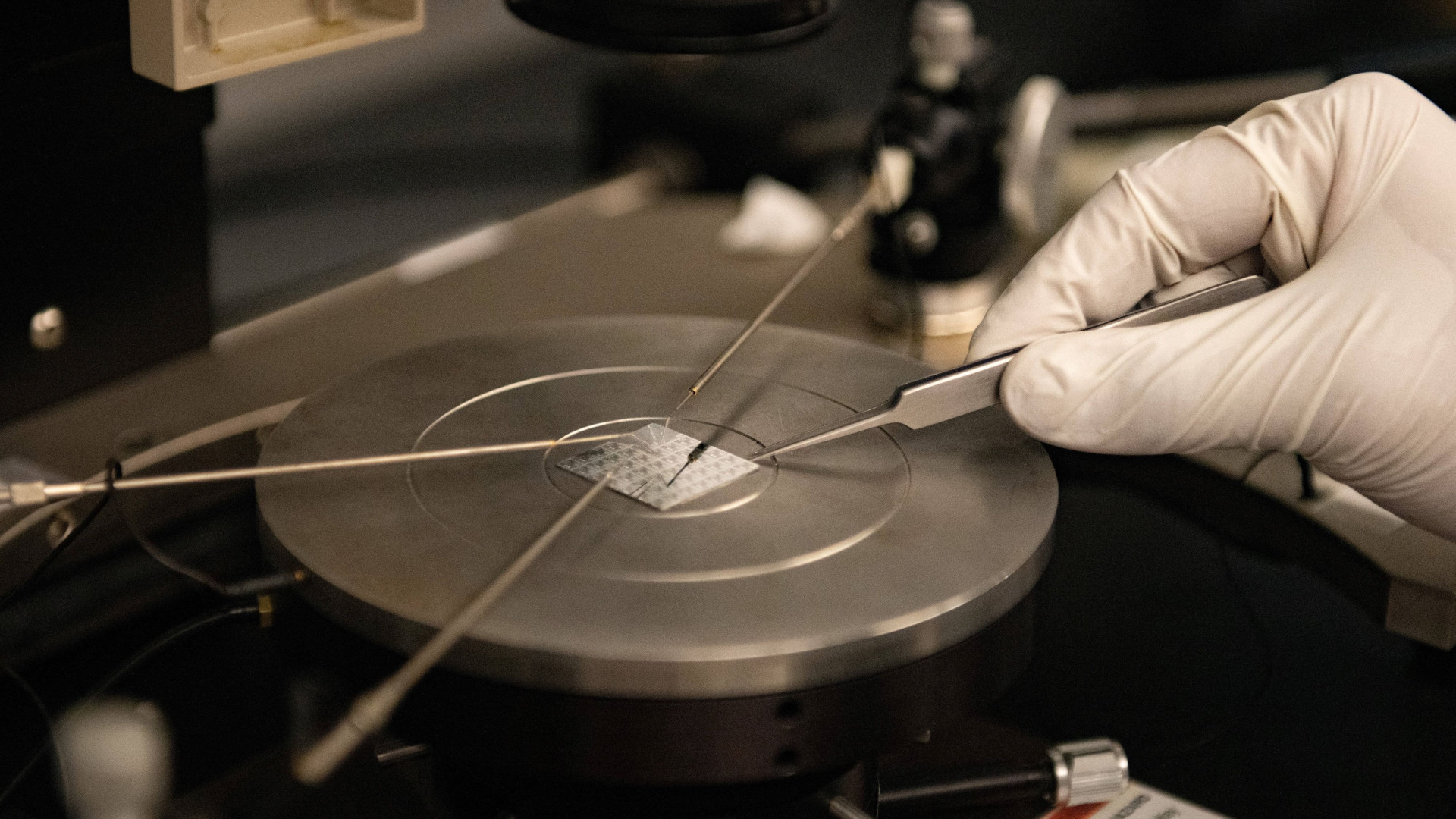

But rather than just throwing them all in a tub and stirring furiously, the team used a more rigorous process. The supplementary data sheet for the research paper makes the process sound pretty darn cool.

"The colloidal [liquid metals, LMs] in this study were synthesized via a mechanochemical approach, in which substantial force propelled the LM to infiltrate the crystal lattice of the ceramic particle, establishing efficient LM-solid interactions by coordinating the unoccupied orbit of metal atoms in the LM with the lone pair electrons of nitrogen atoms in the AlN [aluminium nitride]."

The upshot of this "substantial force" is that the new thermal compound has a much lower thermal resistance than some of the best liquid metals commercially available, up to 72% than those tested by the team. As to why the team is interested in developing such a material, the focus isn't any kind of gaming PC but massive data centres.

"The power consumption of cooling infrastructure for energy-intensive data centres and other large electronic systems is skyrocketing," said Guihua Yu, a professor in the university's mechanical engineering department and the Texas Materials Institute.

"That trend isn’t dissipating anytime soon, so it’s critical to develop new ways, like the material we’ve created, for efficient and sustainable cooling of devices operating at kilowatt levels and even higher power."

Best AIO cooler for CPUs: Keep your chip chill.

Best air cooler for CPUs: Classic, quiet cooling.

The rate at which something is cooled is primarily affected by two things: the temperature difference between the hot thing and the coolant, and the path of resistance to the heat flow between them. If the latter is quite high, the coolant's temperature needs to be lowered to ensure that the heat flow is high enough. Drop the thermal resistance and you don't need to have coolant as cold.

For data centres, that means you can reduce how much energy is used to pump coolant around and the team estimates that its new thermal compound can knock up to 5% off the energy required. That doesn't sound like very much but if one scales it across the entire industry, those savings would really add up.

Right now, the material isn't manufactured on any commercial scale but the research team estimate that the material cost for its Galinstan/AIN colloid could be as low as 50 cents per gram. I don't how expensive the process is but it seems to me that this could be one research project that could actually be used in the real world soon.