India has announced a breakthrough that could boost its efforts to grow as a space-faring nation.

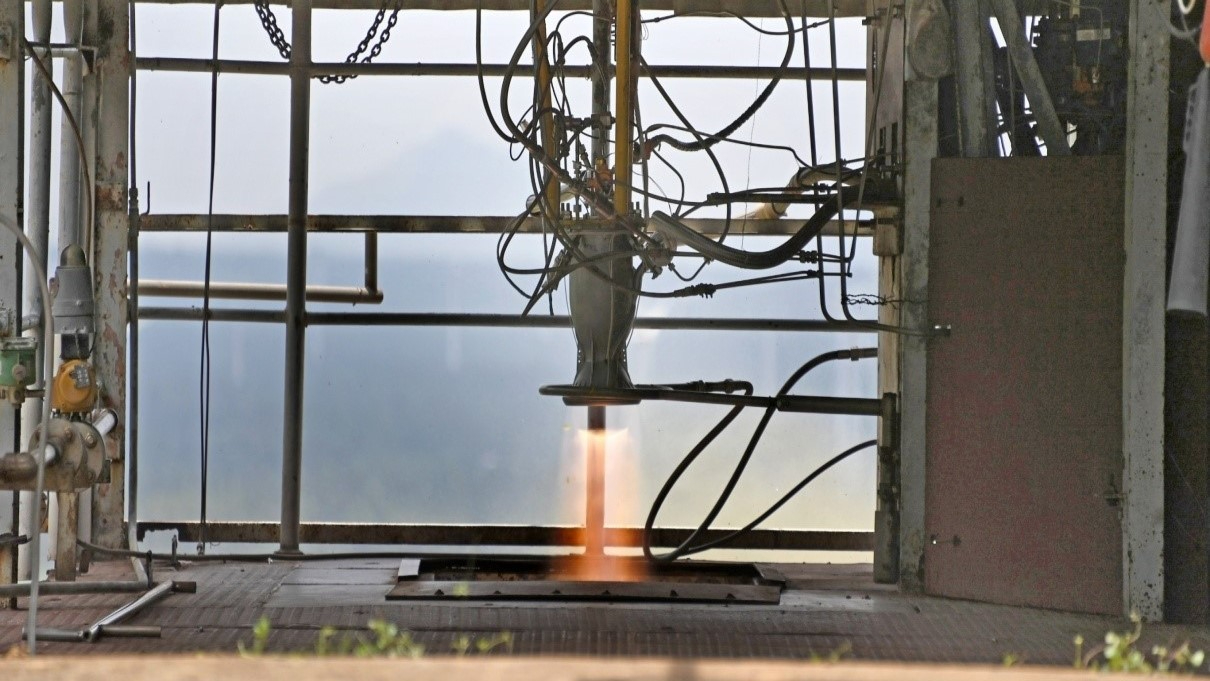

On May 9, the Indian Space Research Organisation (ISRO) performed a successful hot-fire test of a liquid-fueled rocket engine that was built using additive manufacturing (colloquially known as 3D printing) technology.

The engine, which burns a hypergolic mix of nitrogen tetroxide and monomethyl hydrazine, fired for a duration of 665 seconds, marking a major milestone. The engine is used in the upper stage of India's Polar Satellite Launch Vehicle (PSLV).

Related: Latest news about India's space program

ISRO said the new laser powder bed fusion technique used to make the engine has brought down the number of engine parts from 14 to a single piece. This has eliminated 19 weld joints and saved significantly on the raw material usage per engine: The new process uses 30.2 pounds (13.7 kilograms) of metal powder, for example, compared to the 1,245 pounds (565 kg) of forgings and sheets needed with the conventional technique. The new process also reduces the overall production time by 60%, according to ISRO.

Design & Manufacturing Breakthrough:ISRO successfully conducts a long-duration test of the PS4 engine, re-designed for production using cutting-edge additive manufacturing techniques and crafted in the Indian industry.The new engine, now a single piece, saves 97% of raw… pic.twitter.com/YdDsDm3YGFMay 10, 2024

The 145-foot-tall (44 meters) PSLV is one of India's workhorse launchers, along with the LVM-3. The rocket can deliver up to 3,860 pounds (1,750 kg) of payload to sun-synchronous polar orbits 370 miles (600 km) high.

The milestone will help the country boost its launch rate. India also has grand plans in human spaceflight including landing an astronaut on the moon and establishing a lunar base by 2047.