I've been reviewing 3D printers professionally since 2015, and before that, I'd been building them, admittedly with varying degrees of success. Over the years, I've had the privilege of testing a wide range of printers from a variety of manufacturers, and always have a small list of the best 3D Printers that I would readily recommend based on what you want to print, your aspirations and, of course, budget.

If you're just coming to 3D printing, it's a great time to join the community, printer prices are relatively low, and the machines are feature packed. However, there are many machines out there and choosing the right one as your first can be daunting; however, for anyone looking to step into the world of 3D printing, there can be only one that stands out against all others that I would recommend as your first.

With so many options available, what makes this printer so good as a first 3D printer?

If you've scouted the reviews and done your research, there's a huge range of 3D printers, from the cheap to the insanely expensive. When you start your 3D printing journey, it's tempting to go for the cheapest printer you can find, which these days isn't a bad thing; there are a few at around the $200 mark — including the one I'll recommend — that are well worth a look. It's worth noting that if you stretch a little to $300 - 400 dollars, you'll get something that might not necessarily produce higher-quality prints but will be able to grow with you and adapt to how you want to use your 3D printer.

What can you do with a 3D printer?

Almost any object you see manufactured around the home can be made on a 3D printer; from a lamp shade, Shelving bracket to characters used in tabletop gaming, a 3D printer can produce it all.

Why you want a 3D printer will have a bearing on the one you go for and the money you spend. You, like me, could have a fascination with the technology or something more worthwhile like education, gaming, modelling or you may even have a project in mind. A good quality sub-$200 printer will be a great place to start for all of these, and don't be worried by the low cost; you can still create high-quality models that can be used for having fun, modelling, DIY and so much more. The prints may need a bit of a spruce up at the end, but the overall quality that the present crop of sub $200 printers can produce is roughly equivalent to a $500 printer a couple of years ago.

However, dimensional accuracy, fine detail and features should be considered for specific projects such as tabletop gaming characters or prototyping. These cheaper printers may do the job but will need some careful tuning in order for them to do so. The balance between price and quality is interesting, as cheap machines can produce well-tuned models but will require the correct model supports and a little more work, but ultimately the prints should look just as good as those produced by more expensive machines.

However, tuning a cheaper machine requires more patience and a bit of skill, but it's a great way to learn. Adjusting belts and rails, nozzle heights, and filament tensions is necessary for gaining the best quality. Don't worry; fine-tuning your printer isn't difficult, and if you buy one from a larger manufacturer, then the documentation and community surrounding the printers is generally always good. Likewise, the community is always ready to answer questions and guide you through the setup process.

The difference between most $200 and $400 printers is not the print quality but the speed at which they can be set up and calibrated. Of course there are a few additional features such as filament run-out sensors, advanced bed levelling and other safeguards to prevent you from losing a print that you'll also gain from spending a bit more.

If you want prints for modelling, simple gaming or just having fun then dimensional accuracy may not be critical, so a good quality cheap printer will probably suit your needs. A more expensive printer with upgraded features that enables fine-detail and dimensional accuracy is essential for prototyping, jewellery, and more advanced gaming characters so you will need to delve a little deeper into your pockets.

Now, let's consider some features when choosing a 3D printer.

What are a 3D printer's features?

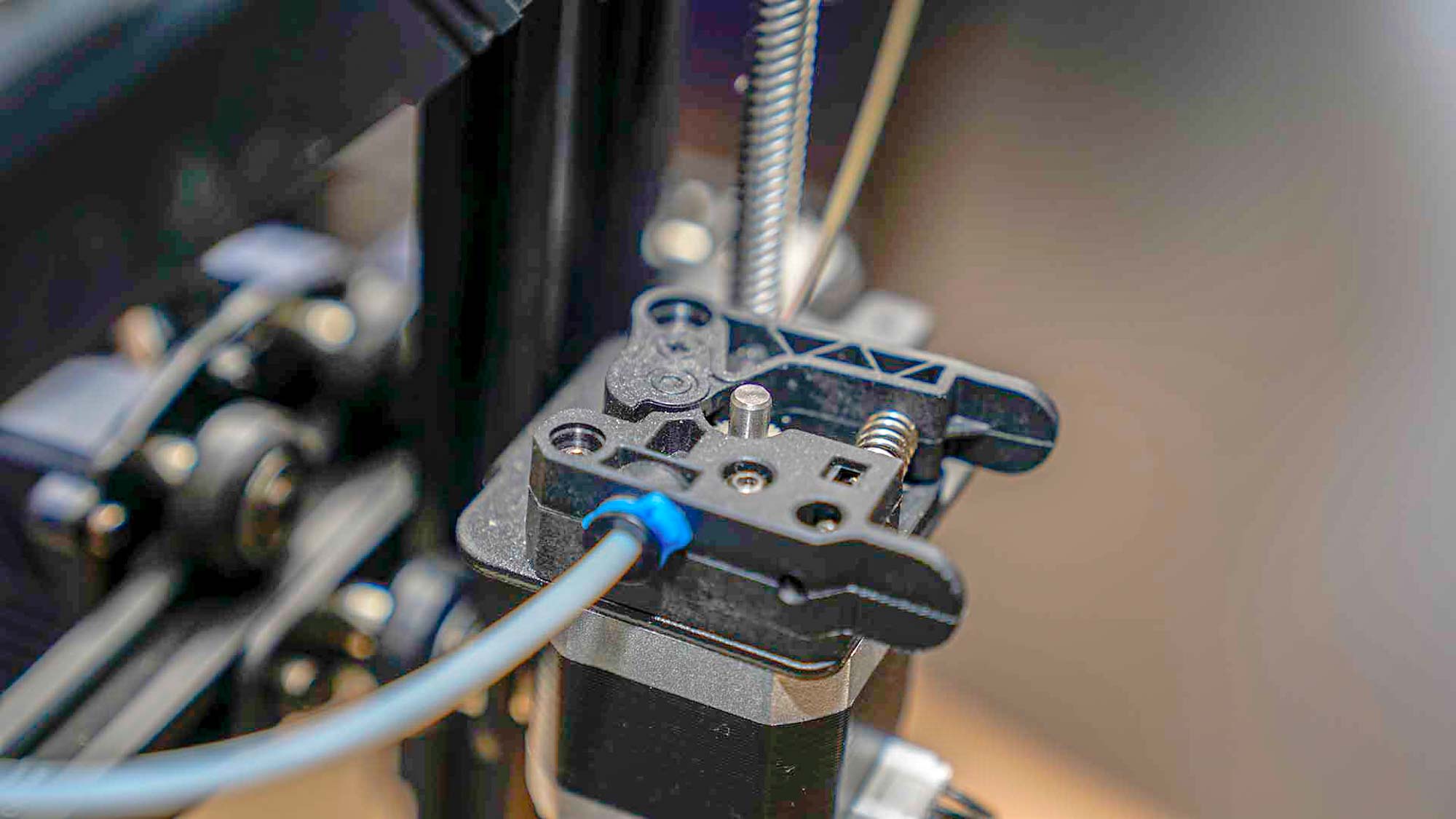

When starting, the machine type you'll want to look at is a cartesian, fused filament fabrication printer, the most common and cheapest printer style. It has a tool head that moves along the Z (Up, down) and X (Left, Right) axis, and a movable print platform that moves along the Y (Forwards, backwards) axis, with a vertical frame, crossbar and base. When it comes to materials, they use a plastic filament, the easiest type of 3D print material to use and handle.

The materials are all plastic based, with PLA being the most common, then ABS, TPU, PETG and countless others, all with different colour combinations and material properties.

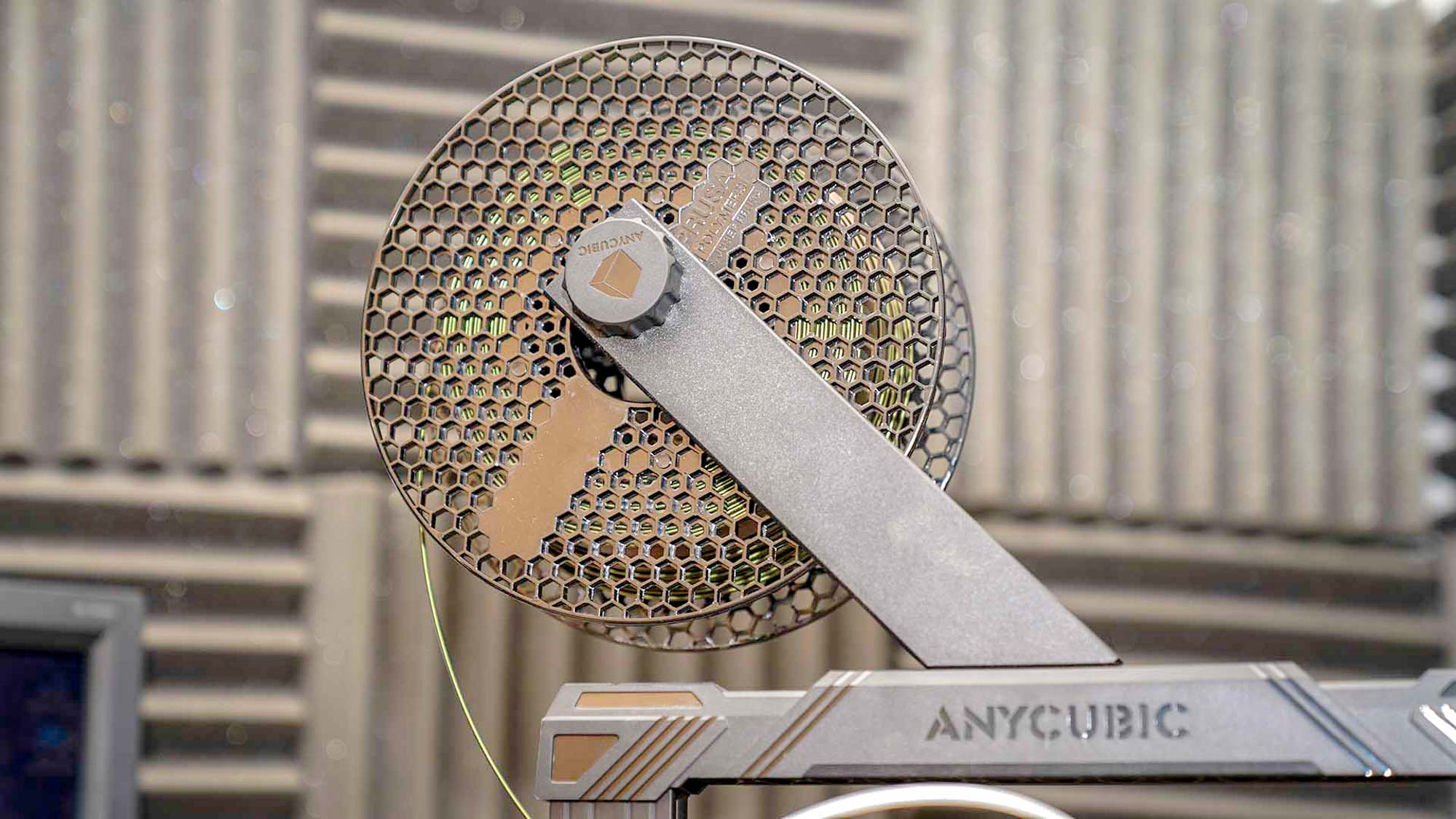

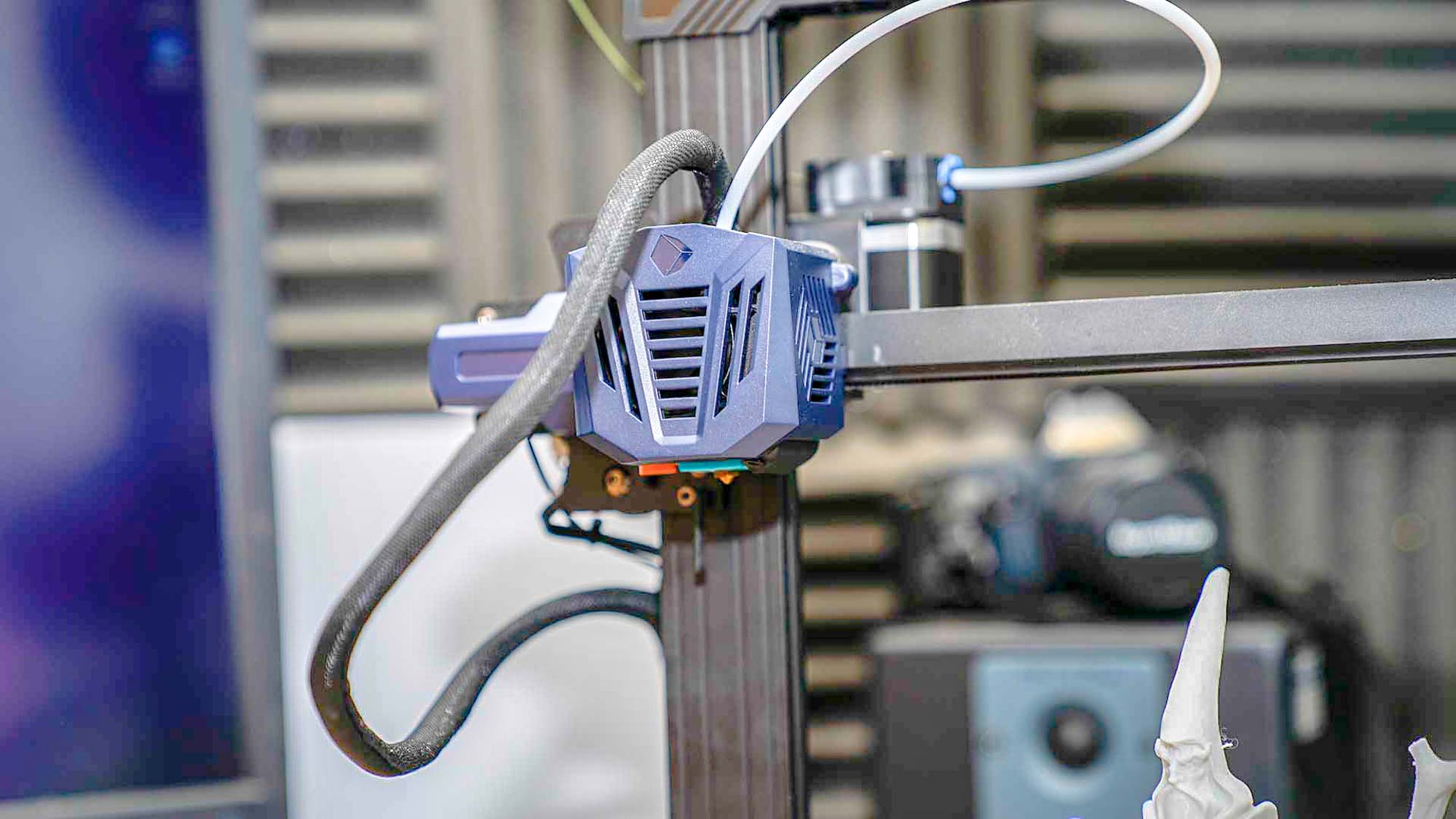

How it works is that the filament is fed into the tool head containing the hotend, nozzle, and extruder. The extruder pushes or pulls the filament through the hotend and into the nozzle, which then deposits the melted filament onto the print platform. When it comes to the print platform, avoid glass when starting out and go for sprung steel and heated; these used to only appear on higher-end machines but are now standard across the board. If the printer says it has a non-heated or cold build plate or platform, then avoid it.

The control board and interface are also important factors. You want something that can give you an idea of what's going on with your print, what models you're loading, and how far along the printing process is. Entry-level models are unlikely to be touch screens, but you should still get an interface.

Now let's move on to the more advanced features that are becoming essential for beginners. The first is auto bed levelling, a standard feature on most printers. This can save you hours of time and frustration in ensuring that your first layer is perfect.

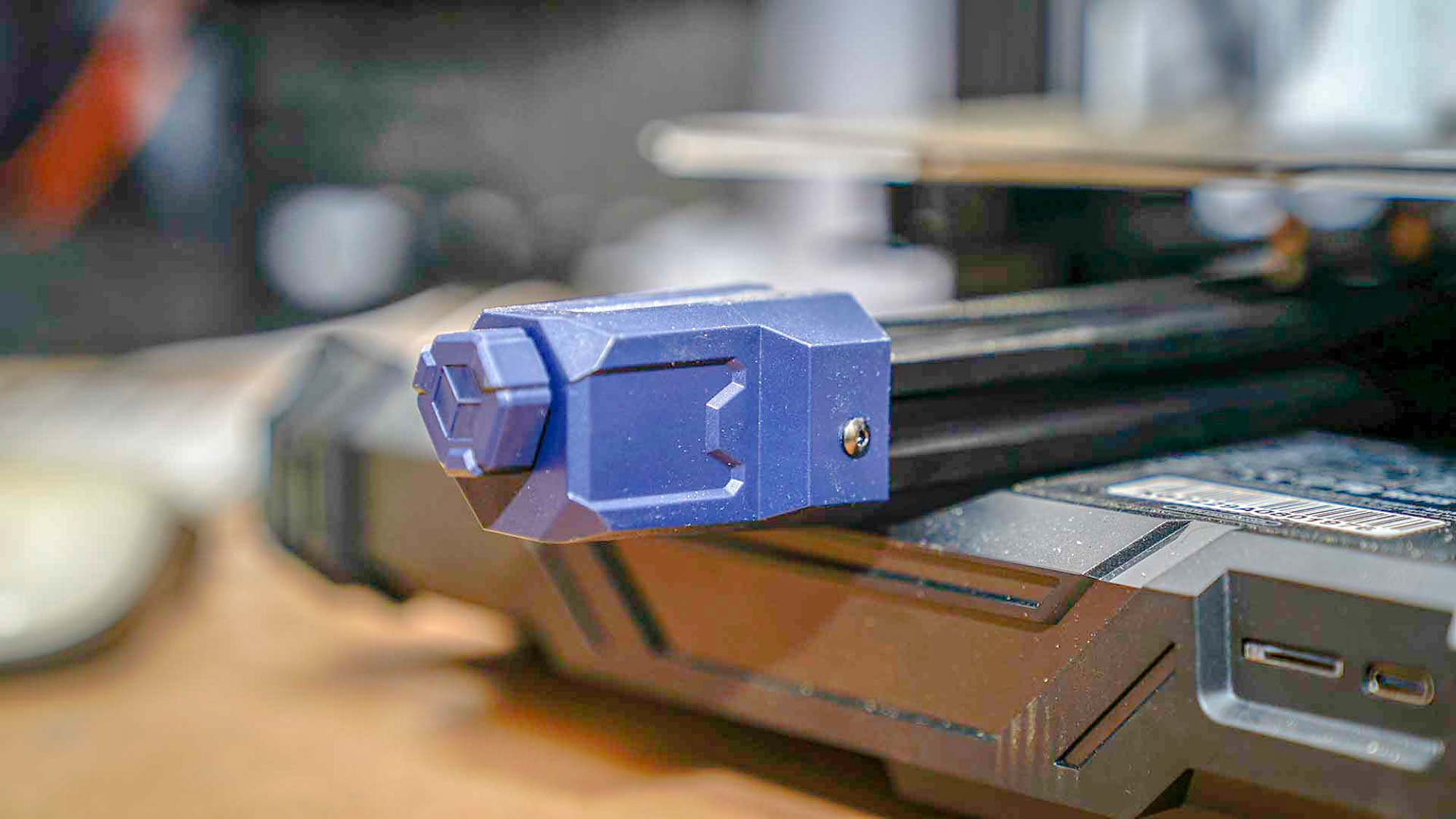

The second feature is a filament run-out sensor, which is nice to have rather than essential. When the filament runs out, it can leave a small amount inside the hotend, which can burn solid, inevitably blocking the nozzle and making it a pain to clear out. A filament run-out sensor stops the machine when the last few inches of filament have been used and pauses until the new filament is fed through.

The noise and speed of the machine are also important. Most 3D printers have now improved print speeds and have addressed the noise issues that plagued earlier models. A printer should run at a speed of at least 60mm/s, with 150mm/s becoming the standard. Look for quiet running as a feature.

Finally, longevity is key. Look for a printer with a good tool head that can be swapped, upgraded, and nozzles changed. This means that it can adapt and grow with you. Many entry-level printers have optional extras that can be added, so even if you can't quite stretch to the model you want, there's often an upgrade route.

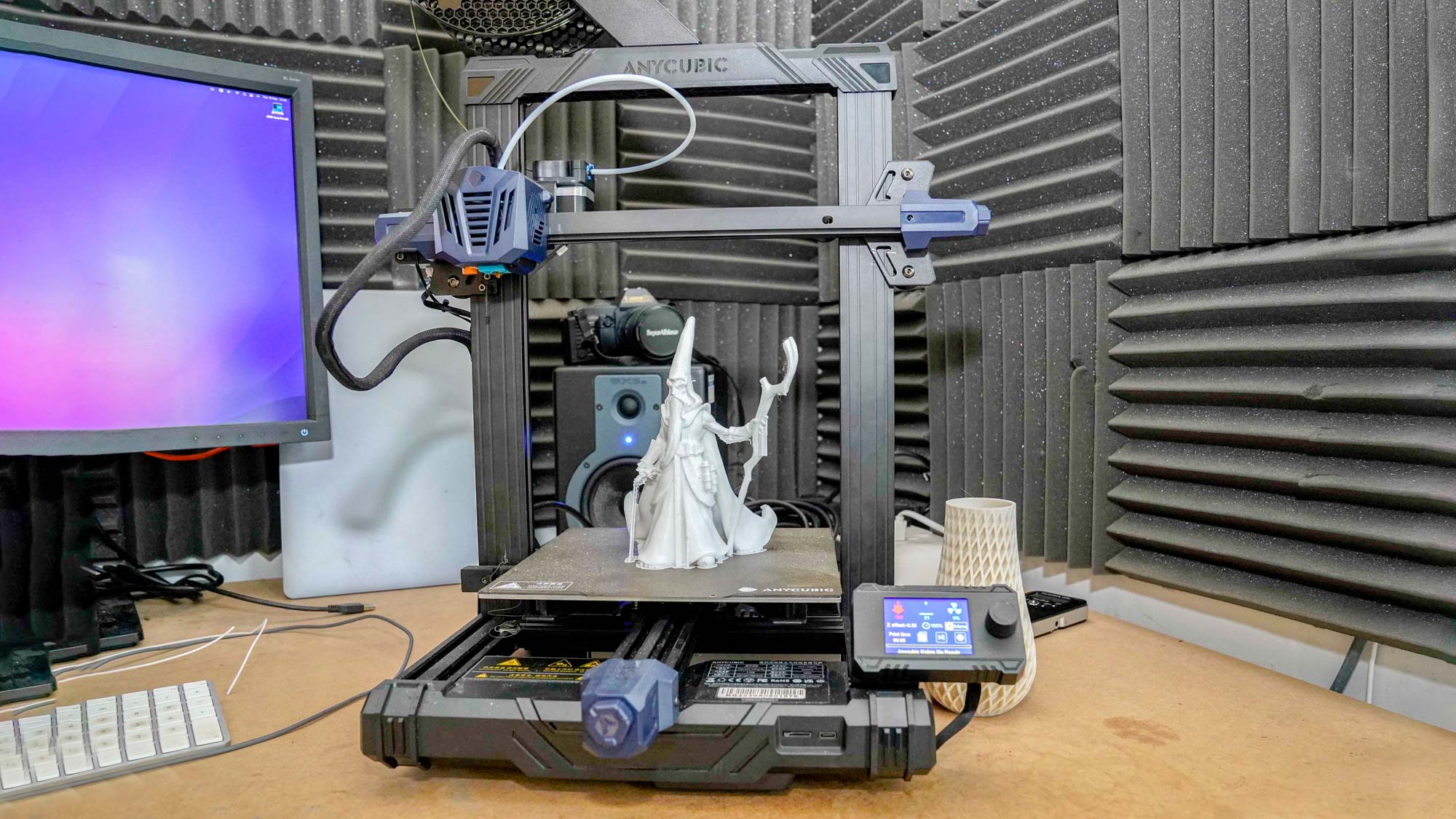

So, which 3D printer stands out as a must-have first buy? There are plenty of options, but above all, I would recommend the AnyCubic Kobra ($299, Amazon). It ticks all the boxes regarding features, with auto bed levelling, a filament run-out sensor is an optional extra, and it features a good control board and interface; it's also fast, quiet, and has a great tool head that can handle a wide range of materials. Plus, it's affordable and has a large community of users who can offer help and support.