Electric vehicles (EVs) clearly represent the future of motoring as the world fights to address the climate crisis and makes the transition towards greener technology and more sustainable sources of power.

But switching away from the traditional internal combustion engine, run on the burning of petrol and diesel fuel, might feel like a drastic leap to some after a century of auto culture and the battery technology on which EVs rely has been greeted with a degree of scepticism in some quarters.

In the interest of dispelling some popular misconceptions, here is a brief introduction to how EV batteries actually work.

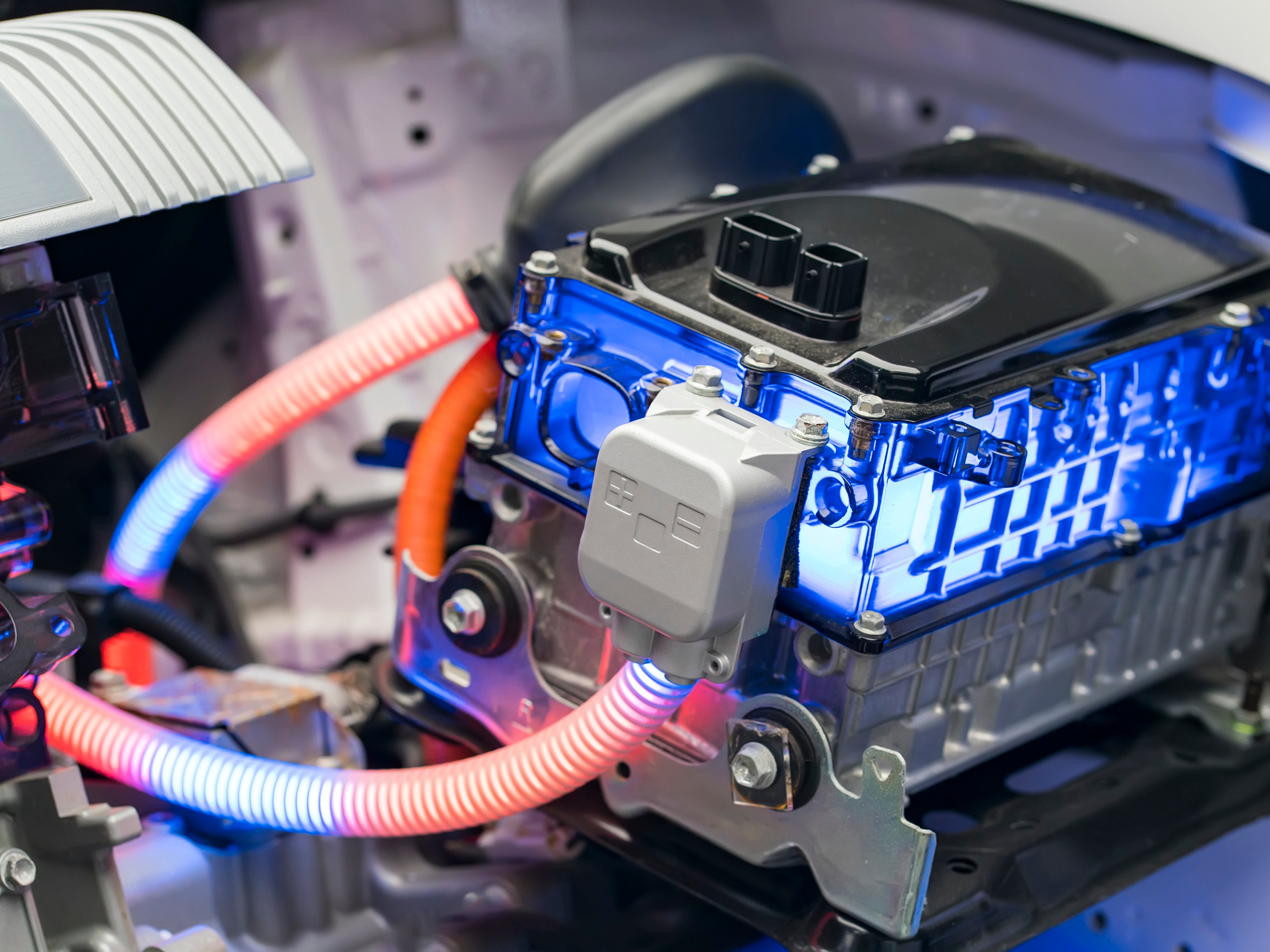

Rather than one lone battery unit, electric cars feature a pack containing thousands of individual lithium ion cells, akin to the one powering your smartphone.

These offer higher energy density than typical lead-acid or nickel-cadmium rechargeable batteries so are lighter and take up less space within the car’s interior.

They operate very simply, connecting to one or more electric motors that in turn drive the vehicle’s wheels.

When the driver presses down on the accelerator, the batteries deliver further power to the motor, a process that gradually consumes the energy stored.

Cleverly, when the throttle is released, an EV begins to convert its forward motion back into electricity, a regenerative process enhanced when braking, which effectively means that thermal energy that would otherwise have been wasted is recycled on the spot back into a kinetic force.

The capacity of an EV’s battery pack is measured in kilowatt hours (kWh), with the most common wattage seen in mainstream electric cars around 40kWh, according to EDF Energy, which delivers sufficient charge to travel around 150 miles or so before the vehicle in question needs to be plugged in again and rejuiced.

At the top of the range, Tesla’s largest battery offering is 100kWh, featured in its Model S, which enables the driver to go more than twice as far, approximately 375 miles, before a recharge becomes necessary.

The technology is progressing all the time, with Mercedes-Benz recently beating its own range record for an EV when its Vision EQXX model made it all the way from Stuttgart to Silverstone in Northamptonshire, a 750-mile journey, on just a single charge.

Advanced aerodynamics, lightweight materials and battery innovations involving the use of state-of-the-art silicon anodes enabled the car to make the trip in under 15 hours on a 100kWh battery pack of its own.

The cycle of charging at a plug-in point and discharging while driving inevitably causes an EV’s battery to wear down over time, as is the case in a phone, although this happens over a much longer period as a vehicle will not necessarily require daily charging, unless you regularly rack up huge mileage.

Most manufacturers feature in-built technology in their cars, from buffering and cooling systems to incorporating additional storage capacity, to compensate for natural degradation over the course of a battery’s lifetime, and all offer lengthy five-to-eight year warranties on this essential unit, with Nissan and Tesla both pledging eight years or 100,000 miles in the interest of putting customers’ minds at rest over the issue.

When an EV battery does begin to lose power and approach the end of its life, it can be recycled for use as part of a larger storage system, perhaps in support of solar panels installed on a rooftop.

Some manufacturers have announced specific schemes to this end, like Nissan using old EV batteries to provide backup power to Ajax Football Club’s home stadium, the Johan Cruyff Arena in Amsterdam, the Netherlands, or Toyota’s initiative to provide retired units to Japanese corner shops for the storage of solar energy on which to run their cold drinks fridges.

If batteries are too exhausted to be reused like this, they can still be broken back down into the raw materials used to build them such as cobalt and lithium salts, stainless steel, copper, aluminium and plastic.

Another positive aspect of EV batteries is that their production cost has fallen dramatically over the last decade, from around £820 per kWh in 2010 to £186 in 2016, according to McKinsey data.

Some experts now predict the expense could fall even further to as low as £82 by 2030, just in time for the phase out of the sale of petrol and diesel cars in the UK at the end of the decade.