A booming petrochemical buildout on the Gulf Coast has drawn billions of dollars in public subsidies from state tax abatement programs despite regular violations of pollution permits, according to a new report released Thursday.

The Environmental Integrity Project, an environmental nonprofit based in Texas and Washington, D.C., compiled data on all U.S. plastics projects built, expanded or proposed since 2012, almost all of them along the Gulf Coast.

The report identified 50 plastics complexes built or expanded in the last 12 years, 33 in Texas. Together they have drawn a total of $1.65 billion in property tax breaks through the state’s Chapter 313 program for energy and manufacturing companies, which the state legislature replaced last year with a new but similar program.

That’s a tiny dent in Texas’ $250 billion annual tax revenue, but it’s just one visible slice of the total concessions corporations receive to do business in Texas, and it represents lost income that would have gone primarily to the state’s public schools, which are struggling with shortfalls in teachers and funding.

Now, companies are proposing to build an additional 42 plastics plants, 24 of them in Texas, according to the 73-page EIP report, “Feeding the Plastics Industrial Complex.”

“The industry is expanding rapidly, and more communities are being asked to consider public subsidies,” it said. “None of the state programs we examined require industries to follow the terms of their state pollution control permits.”

While Texas hosts the most new plastics production, the most generous tax breaks come from neighboring Louisiana, among the nation’s poorest states, where three projects alone drew $6.5 billion in local discounts since 2013. All operating projects considered in the EIP report claimed a total of $9 billion in exchange for commitments to economic development and job growth.

That money would have otherwise funded local schools and public services, said Alexandra Shaykevich, research manager at the Environmental Integrity Project. Instead, it’s given to highly profitable corporations that are often foreign-owned and likely would have located near the nation’s major oil and gas resources with or without local tax incentives, according to her group’s report.

Most facilities reviewed by the EIP reported repeated violations of their pollution permits, Shaykevich said, but those violations never jeopardized their tax subsidies.

“I think if companies can’t obey the law they shouldn’t be rewarded with taxpayer money,” she said. “We would certainly advocate for making subsidies conditional on compliance.”

The American Chemistry Council and the Texas Chemistry Council, which represent the plastics business, did not immediately respond to requests for comment.

Texas Sen. Charles Schwertner, chair of the Senate Committee on Business and Commerce, said the state’s tax incentive program “bolsters economically distressed communities and enhances its competitive advantage in attracting vital industries.”

“The program ensures that the Texas economic miracle continues to thrive by offering quality employment opportunities for Texans and investments in our communities,” Schwertner said.

Gulf Coast Expansion

The recent growth in Gulf Coast petrochemicals, which include plastics, are a result of the ongoing boom in hydraulic fracturing upstream in the Eagle Ford Shale and Permian Basin of Texas. Pipelines carry oil and gas hundreds of miles to the coast, where refineries and chemical plants produce commercial products and load them onto ships for sale overseas.

The United States . remains a world leader in petrochemical production and export thanks primarily to these industries, said Joe Powell, executive director of the Energy Transition Institute at the University of Houston.

“We’ve got really good energy prices here on the Gulf Coast because of fracking,” he said. “That makes the U.S. Gulf Coast a really good investment opportunity, especially in petrochemicals.”

Within plastics, he said, most recent growth has come from ethane crackers, facilities that turn natural gas into ethylene, which, according to the American Chemistry Council, can be made into polymers that are “used to manufacture fibers, bins, pails, crates, bottles, piping, food packaging films, trash liners, bags, wire and cable sheathing, insulation, surface coatings for paper and cardboard, and a wide variety of other products.”

The U.S. is the top exporter of ethylene polymers, much of which go to China, the world’s top importer.

Powell, a former chief scientist for Shell, the global energy company, said years of rapid expansions have brought a glut of ethylene to market and left the Gulf Coast overbuilt in the short term, which he called “typical of the chemical business.”

But in the long term, robust demand for plastics is expected to grow. The Paris-based Organisation for Economic Co-operation and Development predicts global plastics demand will triple between 2019 and 2060. Much of that supply will come from Texas.

High demand for plastics and other petrochemicals will support a growing share of fossil fuel production, said Tom Sanzillo, a director of financial analysis at the Institute for Energy Economics and Financial Analysis, as major sectors like transportation fuels and power generation shift to more sustainable forms of energy.

Proposed Projects in Texas

For its report, the EIP drew on public records, including permit applications and company announcements, to compile a list of currently proposed plastics projects. Their data shows a wave of new development is still planned for the Texas coast, including seven new complexes and 20 expansions at existing complexes.

For example, it said Formosa Plastics, a $460 billion Taiwanese company, has proposed to build a new vinyl chloride reactor, which produces material for PVC plastic, at its 2,500-acre Point Comfort complex on Lavaca Bay. (The company has quietly advanced other expansion plans lately, as well.)

At neighboring Matagorda Bay, German petrochemical manufacturer Roehm plans to turn greenfields into a new plant to produce methyl methacrylate, a component of common construction plastics.

In Corpus Christi, a joint Singaporean-Taiwanese-Mexican venture plans to build a new manufacturing complex for polyethylene terephthalate, a common plastic in disposable packaging, named “Project Jumbo.” The complex, proposed by the companies Indorama, Far Eastern New Century and Alpek, will also include a desalination plant to pull seawater from Nueces Bay.

Near Houston, ExxonMobil plans three major expansions at its massive Baytown complex: a new cracking furnace, expansion of its polypropylene plant and a new hydrogen plant to power those and other units.

The highest concentration of proposed new plastics complexes surrounds Port Arthur, a small city ringed in heavy industry that boasts some of the last available ship channel waterfront on the Gulf. There, Motiva Enterprises, owned by the government of Saudi Arabia, has proposed a new ethylene unit consisting of eight furnaces next to its existing Port Arthur refinery. Ethylene is produced by heating natural gas or petroleum to above 800 degrees Celsius, which produces a mixture of gases from which ethylene is separated.

Texas-based companies Energy Transfer, Enterprise Products Partners and Chevron Philipps Chemical have also proposed new complexes of ethylene and polyethylene units in the area.

“Our local government and our state government welcomes this activity, but the people who live in the shadows of the industry are the ones who continue to suffer,” said Hilton Kelley, 63, a community organizer from Port Arthur. “In most of these situations around the nation, you will find that it’s people of color.”

Forty-three percent of Port Arthur residents are Black, more than three times the statewide average. Much of the city is in the 95th percentile nationally for both the volume of toxic air pollution released and resulting cancer risk, according to the U.S. Environmental Protection Agency.

“We’re just like a dumping ground,” said Kelley. “A large number of my friends and relatives have died from cancer.”

But despite the abundance of multibillion-dollar industries in Port Arthur, median household income is 37 percent less than Texas as a whole while its poverty rate is nearly double.

“Even if the community speaks out, permits are almost never denied,” she said. “We’re constantly showing them the problems, we just get ignored and they get the permits.”

State Tax Abatement Programs

In its report, the EIP found at least two-thirds of the 50 recently completed plastics projects it reviewed nationally received tax abatements through state or local governments.

Of the top four recipients, three were in Louisiana, drawing a combined $4.6 billion from the state’s Industrial Tax Exemption Program since 2013, and one was in Pennsylvania, a massive Shell ethylene plant in Beaver County outside Pittsburgh, which drew $1.65 billion from Pennsylvania’s Resource Manufacturing Tax Credit. All were owned, in part or in full, by corporations from Asia, Africa or Europe.

The fifth top recipient was Dow Chemical’s Freeport chemical complex in Brazoria County, which received $393 million in operating discounts since 2013 through Texas’ Chapter 313 tax abatement program. Dow did not immediately respond to a request for comment.

“It sounds like a lot of money. But in this game that some people would call interstate competition for growth and others would call corporate welfare, it’s not an overwhelming amount,” said Mike Kraten, director of accounting program initiatives at the University of Houston’s Bauer College of Business. “I think anyone would agree that this has become par for the course.”

Chapter 313, one of many tax abatement programs in Texas, represents a small slice of the total incentives that companies may receive to invest here. The biggest concessions are typically custom-negotiated in private between company lobbyists and state or local governmental development offices, Kraten said.

Chapter 313 drew criticism from both Republicans and Democrats in Texas. The conservative think tank Texas Public Policy Foundation called it“unnecessary and wasteful.”Texas doesn’t need to offer tax incentives, critics argued, because its oil and gas fields mean companies will locate here anyway.

Last year, the Texas Legislature replaced the Chapter 313 program with a similar program called Chapter 403, which the think tank Every Texan called “better in some ways, worse in others.”

According to Dick Lavine, a senior analyst at Every Texan, two 403 agreements have been signed to date. Meanwhile, the Texas comptroller’s office shows 872 tax abatement agreements still active under Chapter 313.

Last year, an analysis by the Houston Chronicle showed those outstanding agreements will cost Texas taxpayers $31 billion in lost revenue over the next 30 years.

Regular Violations of Pollution Permits

These subsidies are awarded irrespective of companies’ history of compliance with environmental law, the EIP report found. Of the plastics plants it considered, 84 percent had self-reported violations of their pollution permits to state environmental regulators.

“They seldom face penalties and never have their public subsidies revoked, no matter how frequent their environmental permit violation,” the report said.

For example, it cited Gulf Coast Growth Ventures, a huge, new plastics plant outside Corpus Christi, jointly owned by the Saudi Basic Industries Corp. and ExxonMobil, the world’s largest private oil company, which posted a record $56 billion profit in 2022.

Located in the town of Gregory, which is 90 percent Hispanic, the project secured in 2017 a $249 million tax break from the Gregory-Portland Independent School District for the period between 2022 and 2032.

Then, between 2021 and 2022, the facility reported 10 unpermitted pollution releases totaling 560,802 pounds due to equipment failure, emergency flaring or unplanned shutdowns. During one incident in 2022, the glow of burning ground flares was visible from 20 miles away for days, according to the Corpus Christi Caller Times.

The plant also incurred 63 violations from Texas’ environmental regulator in less than two years, according to the EIP report.

“These include failure to comply with limits for pollutants such as nitrogen oxide and carbon monoxide, failure to properly sample and analyze discharges of stormwater from the site, and failing to properly operate and monitor its flares,” the report said.

ExxonMobil did not immediately respond to a request for comment.

All of the top seven U.S. plastics plants that incurred legal penalties for Clean Air Act violations between 2020 and 2023 were in Texas, the report found.

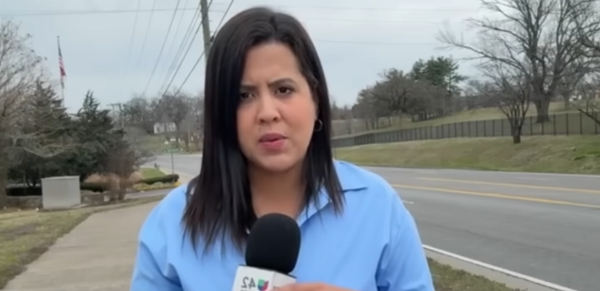

Brandy Deason, climate justice coordinator for the nonprofit Air Alliance Houston, which collaborated on the report, said public subsidies shouldn’t go to companies that harm public health beyond what their pollution permits allow.

Before Air Alliance Houston, she worked at commercial laboratories in Louisiana and Texas that analyzed air samples from industrial operators for their reports to regulators. That’s where she realized what sorts of vapors wafted from refineries and chemical plants—things like benzene, butadiene and all manner of volatile organic compounds.

“I saw the air pollution first hand. I ran it through the instruments. I did the reports,” she said. “I saw a lot of pollution.”

What frustrates her most, she said, was the pointlessness of much of it. While many plastics are now used in construction and high-grade medical gear, much more goes to single-use packaging that wasn’t present in the world just a few decades ago.

And, she said, campaigns by Air Alliance Houston and its allies to slow the pace of plastics expansions authorized by Texas regulators have been largely ineffective.

“Even if the community speaks out, permits are almost never denied,” she said. “We’re constantly showing them the problems, we just get ignored and they get the permits.”