Steelmaker ArcelorMittal is to invest 1.7 billion euros in reducing carbon emissions at two of its plants in France, with financial support from the French state.

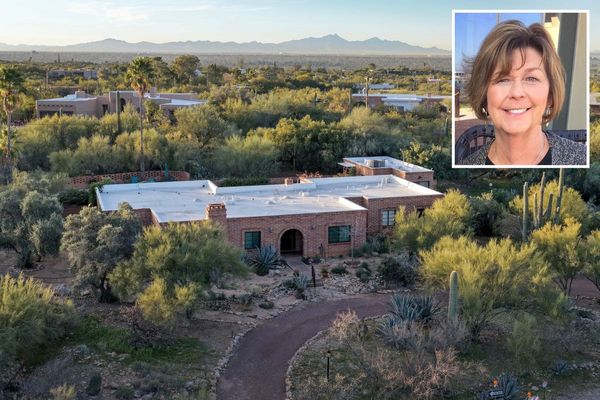

ArcelorMittal has seven steel plants in France – the largest in Dunkirk in the north can produce up to seven million tonnes of steel per year.

The problem is steel production is responsible for 7 percent of the world's CO2 emissions, linked to global warming.

On a visit to the Dunkirk plant on Friday, Prime Minister Jean Castex announced the steel giant was investing 1.7 billion euros in transforming two of its plants, without reducing their production capacities.

The Dunkirk plant will replace two of its three coal-fired furnaces with hydrogen power from 2027.

- France's green hydrogen pioneers aim to revolutionise energy production

- Global temperatures on the rise as world fails to meet Paris agreement emissions targets

The Fos-sur-Mer plant in the south of France will install an Electric Arc Furnace using the electric power grid rather than coal, allowing the plant to specialise in recycled steel.

Those two sites alone account for 25 percent of industrial greenhouse gases produced in France.

The investment will therefore help ArcelorMittal achieve its goal of reducing carbon emissions by close to 40 percent by 2030, the company said in a statement.

The move "put France’s steelmaking industry on the path of the Paris Agreement", the company said, referring to the multilateral agreement signed between 195 countries in 2015 to limit man-made global warming.

State aid

ArcelorMittal will receive funding via the 34-billion-euro "France 2030" investment programme, although the precise sum has not been revealed.

More than 5.5 billion euros of that fund have been earmarked to help the highly polluting steel-aluminium, chemical and cement sectors to reduce their CO2 emissions.

In the run up to April's presidential election, Emmanuel Macron's government is looking to step up investments in northern France – traditionally one of the country's industrial heartlands – but which has been hard hit by factory closures.