The FormLabs Form3+ is a distinctive-looking machine with a weighty build and refined quality that instantly highlights this as a high-quality machine. Yet, while the price might put it out of reach for most home users if you're serious about finding the best 3D printers out there - and demand absolute quality, then the Form3+ should be the printer you aim for. However, the core audience is businesses looking for a solution for producing high-quality prototypes or production parts. The quality of the print ensures accuracy and fine detail, while the range of materials offers a greater range of long-term applications for the prints that you produce.

FormLabs has also looked at the entire resin print process, as there's only an escape from the mess that resin can make if you follow a set procedure. Here, FormLabs has first made a machine that pretty much handles the full flow of resin into the machine through the print process so that once the resin tank is installed, the only time you need to get your hands dirty is when you remove the print, ready for cleaning and curing. Even here, at the most time-consuming part of the process, FormLabs has you covered with the cleaning and automated wash and cure system that all makes the process nice and easy and as clean as possible.

FormLabs Form3+: Design

In this review, I'm purely focusing on the main machine, the FormLabs Form3+, which is the resin 3D printer itself. However, throughout the test, I coupled the use of this with the FormWash and FormCure machines. I also tested the cleaning and curing with other machines, but I will say from the outset that the quality of wash and cure is a huge step up when you use the FormLabs machines.

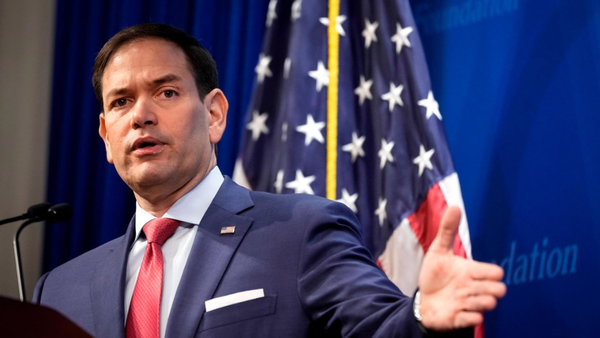

Looking at the Form3+, the design of this SLA printer is instantly recognizable with the orange protective cover, dark grey base, and large LCD screen. While the technology of the machines has developed along with the design, the machines themselves still reflect the company's distinctive style.

Setting up the machine is relatively quick once it is removed from all the packaging. As the printer is removed from the box, the weight is instantly apparent, as is the high-quality build that gives the machine a high-quality look and feel.

Once everything is laid out, the actual setup process is incredibly quick. First, the resin cartridge is installed, then the build platform is installed and locked, and finally, the Resin Tank is installed with the wiper clicked into place. Once those components are installed and the machine is switched on, sensors check that you have done everything correctly, and essentially, you're ready to start printing.

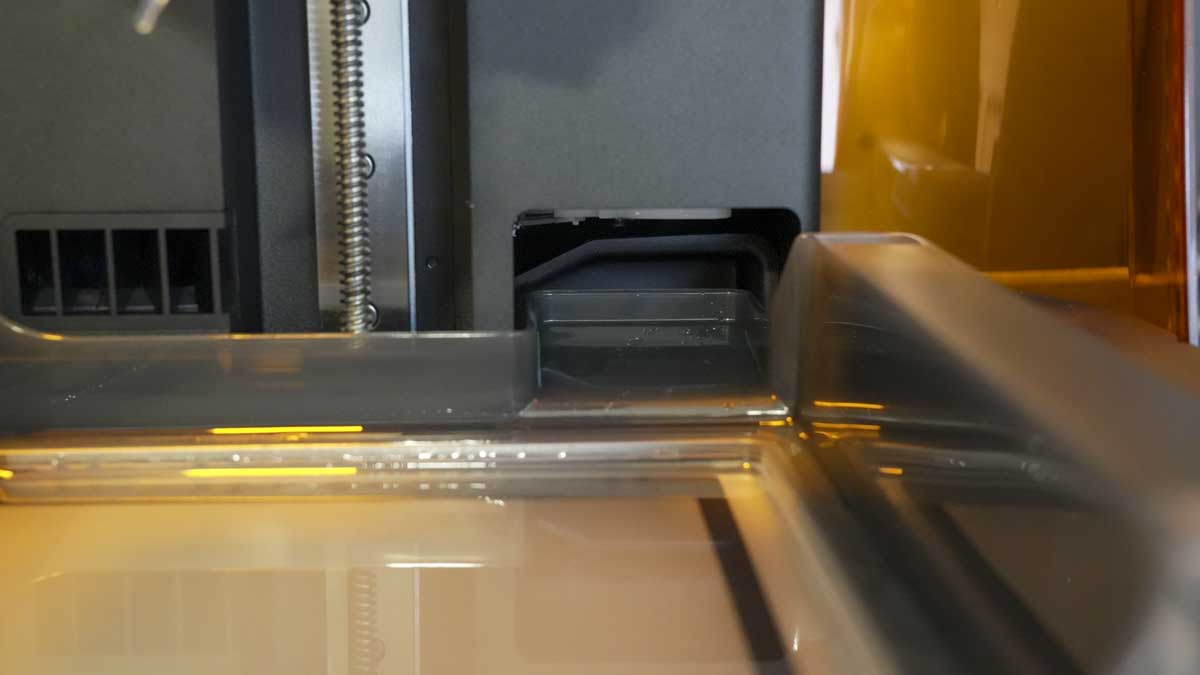

There are a few points to the design which really stand out. Firstly, the cartridge and tank are designed in such a way that you can swap materials easily. Simply close the vent cap on the cartridge and withdraw, and the cartridge can be stored for use. Likewise, the resin tank can be removed and comes with a lid so that, again, it can be safely set aside for a time while another material is used. The resin tanks are designed to be reusable and can be cleaned when needed.

While the resin cartridge simply inserts into the back of the machine, the build platform and resin tank are contained under the large hinged orange cover. This makes everything neat and helps protect you. This also enables the chamber itself to be air-heated, which helps with the overall quality of the prints with each of the different materials.

One of the interesting features of the Form3+ and the resin tank is that the film is held under tension, which aids with the quality of the finish that is produced. Also, unlike other machines that use an LED matrix UV light source, the Form uses a far more accurate Class 1 Laser, which instantly enables it to produce far higher quality prints and widens the resin options that you can use.

However, this does mean that some of the FormLabs specialist resins are eye-wateringly expensive compared to the open resin options, including more standard 405nm photopolymer resin, which can be purchased at a fraction of the price of some of the FormLabs options.

Finally, one of the big features of the machine when it comes to its pure ease of use is the large touchscreen on the front. This essentially guides you through the process, from setup to print, as well as giving you information about the print process. The screen and its user interface simply make tracking the print and the status of the machine easy with a visual representation of what is going on. This interface also enables you to connect the machine to your WiFi connection so that you can upload models directly from your computer installed with PreForm and monitor the print through the browser interface. However, there's no camera for a live feed.

The design of the Form3+ makes the print process easy. While this machine is more expensive than many of the resin 3D printers out there, it uses true laser technology. It opens up material options far beyond what other resin printers can presently offer. In its design, it also offers a full ecosystem, from the slicing and monitoring software all the way through to the final print.

FormLabs Form3+: Features

Compared with the bulk of 3D printers, many features of the Form3+ will appear distinct, even when contrasted with the latest resin printers. The primary difference is that this is a laser system rather than an LCD, which essentially means that the focused laser of the Form3+ is far more accurate and ensures far more precise curing of the resins than the LCD equivalents. So, if you're prototyping or manufacturing parts, a jeweller, dentist, or engineer, then the Form3+ with its laser technology is the best choice. Whereas, as a hobbyist, the LCD resin printers are good but need help to compete when it comes to absolute accuracy and detail.

When it comes to the laser itself, the Form3+ features a 250 mW laser that provides pinpoint accuracy for high-precision materials and makes it possible to print intricate details and boost the quality of print well above that of its LCD counterparts.

The Form3+ takes this technology a step further with the Low Force Stereolithography (LFS) technology. This essentially enhances print quality by reducing stress on parts, ensuring the print releases from the tensioned flexible screen easily during printing, resulting in finer detail and a smoother finish.

One of the big issues with resin 3D printers has always been the size of the build area. However, the 14.5 × 14.5 × 19.3 cm build platform of the Form3+ is a decent size and, while not as large as many FDM printers, is absolutely fine for many 3D print jobs.

One of the features that has really stood out throughout the review is the fast-change resin cartridges and tank. Not only are these easy to remove and replace, but FormLabs has ensured that there is a way to store and clean the components easily when possible.

Print Technology: Low Force Stereolithography (LFS)™

Build Area: 14.5 × 14.5 × 19.3 cm

Minimum Layer Resolution: 25 microns

Maximum Layer Resolution: 300 microns

Dimensions: 40.5 × 37.5 × 53 cm

Weight: 17.5 kg

Bed: 14.5 × 14.5 × 19.3 cm

Print Surface: Metal

Software: Compatible with PreForm software; supports STL, OBJ, and 3MF file input.

Materials: Compatible with a wide range of proprietary Formlabs resins.

Print Speed: Not specified

One of my pet hates with resin printers is the post-print process. Here, with the Form3+, the Auto-Generated Light-Touch Removal Supports make print removal a lot easier. A simple twist of the print from the build platform is often all that's needed, or with more delicate prints; snips can be used. Either way, the initial support removal is designed to be easier than with most other resin options out there.

Having a heated chamber is something that we're starting to see on the latest resin printers, and it really does make a difference. Essentially, this keeps the print area at the optimal temperature for the resin. As the Form3+ system is so integrated, this is all handled automatically for you based on the resin that you have inserted.

Material compatibility is an important factor for many 3D printing tasks. However, with Form3+, materials are designed with purpose, and the machine adapts the settings to accommodate the huge variety of specialist materials. It's worth noting that these materials are expensive, as they're all pro-grade with different characteristics, so make sure you buy the materials you need - on average, these will set you back around $120 / £120 or above per cartridge, over double standard 405nm photopolymer resin. The good news is that 405nm photopolymer resin can be used if you want a cheaper material solution.

Two major features really help with the machine's workflow. The first is the touchscreen. This provides an intuitive interface for easy control and navigation through the printer's settings, although, for the most part, the printer will handle everything for you. Otherwise, once connected to the WiFi network, you can control everything through the PreForm software. This software is outstanding and enables you to adjust the models, supports, and everything you need about the model. There's also a web browser interface that enables you to monitor the print, which is handy.

Along with the printer comes a range of accessories, the obvious ones being the materials, resin tanks, and build platforms. Alongside these are the Form Wash, Form Cure, and finish station. If the budget allows, then these accessories are well worth the extra expenditure as they will help to boost the overall quality of the print and finish by giving you all the tools you need to clean, cure, and finish the prints properly.

FormLabs Form3+: Performance

There are several traits of the prints that emerge from the FormLabs printer that make them stand out when compared with other 3D printers. The first is the finish, which, with the tough grey material, was almost indistinguishable from an injection-moulded part once fully cleaned. The level of detail and the absolute accuracy and consistency of the parts are just well beyond what you expect from an FFF 3D printer.

Even compared with other resin printers, albeit LCD rather than laser, the quality of the print is different, with the higher rate of precision from the laser ensuring that the print quality and level of detail were taken up a notch. However, it's worth pointing out that the latest LCD printers are exceptionally good, and while there is a quality difference between this and one of the cheaper models, that gap that existed is closing.

Examining the quality of the prints, they look great. There are some minor blips in surface quality, but overall, the prints are well-produced, with little signs of stringing.

As the print tests became more technical, such as running the Autodesk Kickstarter test, the printer's small limitations became apparent. Issues like negative space and bridging fell slightly behind what I've seen from other printers recently. However, the overall surface quality is good, with visible layering that is precise, and the top surfaces of prints are generally well-finished.

For the majority of prints, there is little to fault. The print quality is above that of most entry-level printers, though it doesn't quite meet the quality of finish of high-end models.

FormLabs Form3+: Print quality

However, there are several points that you find when using the printer, which means if I had the money, then the Form3+ is definitely the printer that I would opt for without a doubt. It's also the printer that I would recommend for any business needing a production-quality model.

The first of the points around performance is the workflow. While other printers are quickly catching up, they're still far from the absolute ease of use. The cartridge system is simple, as is the tank design; you literally insert it, and then you're ready to go. Likewise, there's no faffing around with adjustment; the machine does everything on that front for you, including filling the tank and making sure that the temperature and consistency of the resin are correct for the best possible quality print.

Once the print has finished, the platform releases easily, and being the build platform 2, a quick push of the handles and the print pops off without the usual battle to release the print. Then it's just a case of dropping into the Form Wash, removing the supports, and then into the Form Cure to finish.

Essentially, FormLabs has created an entire ecosystem that makes the process as mess-free as possible, although eliminating all the stickiness isn't quite yet possible.

Once the print has fully dried, it can then be worked so that if there are any remnants of the support structure, these can be removed with a file, snips, or knife. Generally, the prints came out relatively clean and ready for use. One of the main projects for this project was to create a focus bracket for an Arri Alexa follow focus; this required absolute accuracy, although simple. This proved to be a simple enough project for the printer in one of the tough materials and was immediately put to use.

Likewise, other functional parts were easy to make and support with the Light-Touch Removal Supports that are generated by the software, holding the model firm during the printing process and then ripping free relatively easily once the wash process is complete. Under a bright light, the prints can then be inspected and cleaned before curing. I found that once the wash had been completed, I would remove the supports, brush away any support debris, and then give another quick wash before curing.

If any supports are left in place during the curing process, then on some models, they're almost impossible to remove due to the strength of the materials.

When it came to detail, these models showed a quality and level of detail that no FFF printer that I have used can come close to competing with. Even the best of the LCD printers with their high-resolution screens are left behind when the printer is switched to the highest quality setting.

The surface finish and detail are also exceptional, and while you do have to clean up the prints to a greater degree than with many FFF models, the quality is just outstanding. For me, the real advantage of Form3+ is the Light-Touch Removal Support. Unlike other printer software that creates support structures that are almost impossible to remove, the PreForm software enables you to balance the support structure perfectly.

While this is aimed at the professional market and businesses such as architecture, engineering, jewellery, film, and many more, this printer will also benefit model makers and other craft enthusiasts looking for absolute quality and precision.

FormLabs Form3+: Final verdict

The FormLabs Form3+ is by far the best in its class, sitting between LCD, DLP, and true SLA printers. At its price, it may seem expensive, especially if you have been looking at the lower end of the resin market, but in reality, this is one of the cheaper SLA printers out there.

As FormLabs has been in the market for quite a few years and has a large user base, it's no surprise that they have managed to create a resin printer that manages to streamline the process and, if not eliminate the mess, they have given you the tools to help improve the workflow and keep things as neat, tidy, and sticky-free as possible.

When it comes to the printer, it's a decent size and will take up quite a bit of desk space. But then, it's also worth considering additional space for the Form Wash and Form Cure machine, which, although smaller, are still a sizable footprint. On top of this, you'll also need a bit of spare work surface for the cleaning station. However, due to the advanced nature of the materials and that outstanding support structure, the prints produced cleaned up far quicker than any other model of printer that I have used, and actually, much of the hard work is removed with those light-touch supports.

As a complete high-quality 3D print solution for high-quality models, the Form3+ is hard to beat due not only to the quality of the machine but also to the workflow and ecosystem that makes what has been a time-consuming process in the past so much easier.

Should You Buy the FormLabs Form3+?

We tested the best 3D modeling software - and these apps really bring creations to life