Originally located in San Francisco, Pac-12 Networks recently moved its broadcast studios to the Bishop Ranch office park in nearby San Ramon, CA. It’s in this 42,000-square-foot, SMPTE ST 2110-compliant space that operators will now oversee the production and broadcast of more than 850 live sporting events each year.

[Cloud-Based Production: Opportunity or Threat for Integrators?]

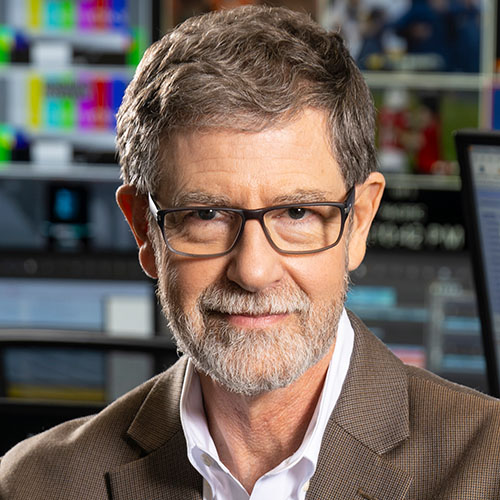

Advanced Systems Group (ASG), a digital media, entertainment, and broadcast engineering solutions firm headquartered in Emeryville, CA, oversaw the design and build for the entire facility, which includes one television studio, five production control rooms, four software-defined production control rooms, five audio control rooms, a graphics bullpen, and a replay room. In partnership with Randy Sparks, founder and managing principal at San Francisco-based technology design and consulting company RLS, ASG also oversaw the acoustic design for the production studios and control rooms.

Pac-12 Networks serves as the content branch of the Pac-12 Conference. The broadcaster comprises seven 24/7 television networks (one national network and six regional networks) and is available through various streaming platforms. Pac-12 broadcasts everything from high-profile football and basketball games to smaller varsity matches.

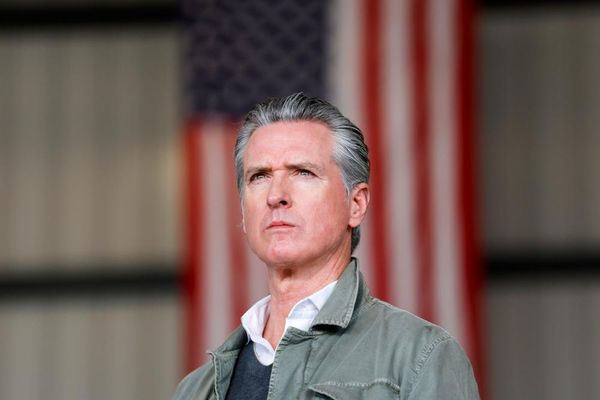

ASG has been working with Pac-12 since the construction of its original facility 12 years ago. “It was pretty revolutionary what they were doing at the time, this concept of taking and backhauling all of the contributions from the venues to a central location—doing all the production that normally gets done for sports in a truck,” said Dave Van Hoy, president of ASG. “[Doing this] in a fixed facility was pretty smart and cost-effective, as it turned out.”

On the Clock

ASG began the design of the new facility in Summer 2022. The firm pitched a time and materials (T&M) model, in addition to a cost-plus approach, in respect of the broadcaster’s defined budget. This was the best pricing approach considering the speed at which the project had to be executed.

“It needed to be collaborative if we were going to make it,” Van Hoy recalled. “From the day that they signed the contract with us to the day that we had to be on air was 364 days, which, for a network sports hub, is a very short period of time [when you’re deploying] from scratch.”

Michele Ferreira, vice president of ASG's systems integration and support, was the overall lead on the project. The ASG acoustics team became the primary coordinator of the physical layout and furniture design, with Erika Lisman, principal acoustical architect, and her team running point. Harrison Gardanier, ASG senior project manager, was the overall project manager, responsible for delivering all aspects of the project to Pac-12, while Mike Surman, senior broadcast engineer, co-led the overall system design effort.

[Cloud Power: Pricing Modern Infrastructures]

It was also necessary to make additions to ASG’s engineering team to move fast. This led to the recruitment of Nik Kumar, ASG technology specialist, who co-led the overall system design effort alongside Surman. This included the ST 2110 integration, for which they collaborated with Steve Young, ASG’s head of systems design.

Young noted that the need for a high level of adaptability in Pac-12’s systems architecture was due to changes that were being made to the broadcaster’s operational requirements after the 2023-2024 season. “The IP-based ST 2110 solution empowers Pac-12 with significantly more flexibility to adapt to future operational requirements without having to redesign the core systems,” he said. In other words, ST 2110 addressed both immediate and future needs.

Pre-Builds and Priorities

The facility is loaded with gear, including Grass Valley K-Frame production switchers, Ross XPression graphics, Evertz DreamCatcher Production Suite and replay servers, Quantum storage systems, High Tech Furnishings furniture, Middle Atlantic racks, and much more. Because of the tight project timeline, ASG opted to prototype as many solutions as possible prior to deploying them. The firm built a lab in the Bishop Ranch location for this purpose, enabling both ASG and Pac-12 team members to collaborate in person in real time.

“When you have a new technology [like ST 2110], you want to be able to lab as much of it as you can,” Van Hoy said. “When you’re in a highly constrained timeline, you want as few surprises at the end as possible.” This exercise wasn’t easy due to continued supply chain disruption. Kumar and Young drove the lab effort, with Garrick Huey, ASG's regional sales leader, working with manufacturers to set up demo gear.

“The lessons learned from applying a multitude of stress tests during the pre-commissioning lab setup early on helped us gauge the system’s conformance to Pac-12’s overall operational workflow requirements and technical standards,” Kumar explained. “We used these lessons to ensure that the critical path to project completion would not be affected, especially given the extremely fast nature of the project.”

At the heart of the software-defined control room is, as the term suggests, a computer running software. ASG's Dave Van Hoy explained that this design approach enables broadcast facilities like Pac-12 Networks to be more cost-effective.

After all, why occupy a $1 million production space when you can get the job done in a room that cost $40,000?

“Within the context of the mission of Pac-12, you’ve got events like football games where there are millions of people watching them, but they also [broadcast] junior varsity lacrosse, and maybe there are 100 viewers,” Van Hoy said. “That’s one of the things that Pac-12 Networks has really mastered: [combining] the right technology with the right production values for the right content.”

In cooperation with one of its subcontractors, ASG leased a pre-build space outside of Atlanta—again, in the interest of moving as quickly as possible. “We had about 50 racks going in there, so we wanted to pre-build and pre-wire as much as we could to make the deadline,” Van Hoy said.

After over a decade operating out of San Francisco, the Pac-12 team had a deep understanding of what was important to them. This sped up the process, Van Hoy observed, since in many projects part of ASG’s job is guiding clients through their real priorities, which takes time. “They were incredibly self-actualized on what was going to matter to them and what wasn’t,” he added.

For example, Pac-12 team members don’t always close their control room doors because they need to move quickly between rooms. Acoustic doors are expensive; if they’re going to be open 80% of the time, it’s not necessary to specify the highest-grade model.

Conversely, the lighting in the TV studio—used for halftime shows and commentary—was very important, as was operator comfort in the control rooms, where much effort was made to optimize sightlines and provide well-designed broadcast furniture. Since there are 2,088 fiber links in the facility, the clean management of fiber optic cables was also a high priority.

Room Design Requirements

The main design goal behind the control rooms and production spaces was that they would operate in a similar fashion. The exception to this is Production Control Room (PCR) 1, which is used for the television studio. “It has all of the camera shading and those functions in it, whereas the others—because it’s all remote contribution—could be a little smaller,” Van Hoy explained.

Interconnectivity between rooms was another requirement. “Let’s say they were doing beach volleyball in Software-Defined Control Room [SDR] 1 and something happened to the computer there, they wanted to be able to jump into SDR 3,” Van Hoy illustrated. “The routing infrastructure had to be able to [accommodate] that, and it’s all set up as presets so that they can jump rapidly. This is sports and there are no do-overs—it’s all live, and so that mattered to them.”

Another important issue ASG needed to address was room-to-room sound bleed. While Pac-12 team members may leave control room doors open much of the time, it was still necessary to isolate production spaces and control rooms. The audio control rooms, equipped with Calrec Artemis digital broadcast consoles, received the highest level of isolation, with higher-grade acoustic doors than the production control rooms.

[See How Prudential Financial Made a Smart AV Investment]

Systems integrators often face what seem like impossible deadlines, and this project was no exception. Van Hoy attributed the project’s success to the level of collaboration between the client, integrator, and all subcontractors involved. “It’s a really forward-facing plant that can do a lot of incredible things,” he said. “I’m incredibly proud of our team who—quite frankly—pulled off as close to a miracle as I think I could describe.”