Scientists are sounding alarm bells about the growing number of satellites burning up in Earth's upper atmosphere.

When incinerated, the materials that make up satellites give rise to chemicals that are known to damage the ozone layer and affect Earth's climate. Does that mean that we should stop launching craft into space?

Not necessarily. Here are four solutions that could help reduce the amount of potentially harmful satellite ash in the atmosphere.

Recoverable satellites

The space industry is booming. Over the past 15 years, the number of satellites in orbit has increased tenfold, and the growth is expected to continue. Within 10 years, 100,000 satellites could circle Earth, 100 times more than in 2010. Most of these satellites will belong to megaconstellations, enormous fleets of tens of thousands of satellites, such as SpaceX's Starlink.

Related: Pollution from rocket launches and burning satellites could cause the next environmental emergency

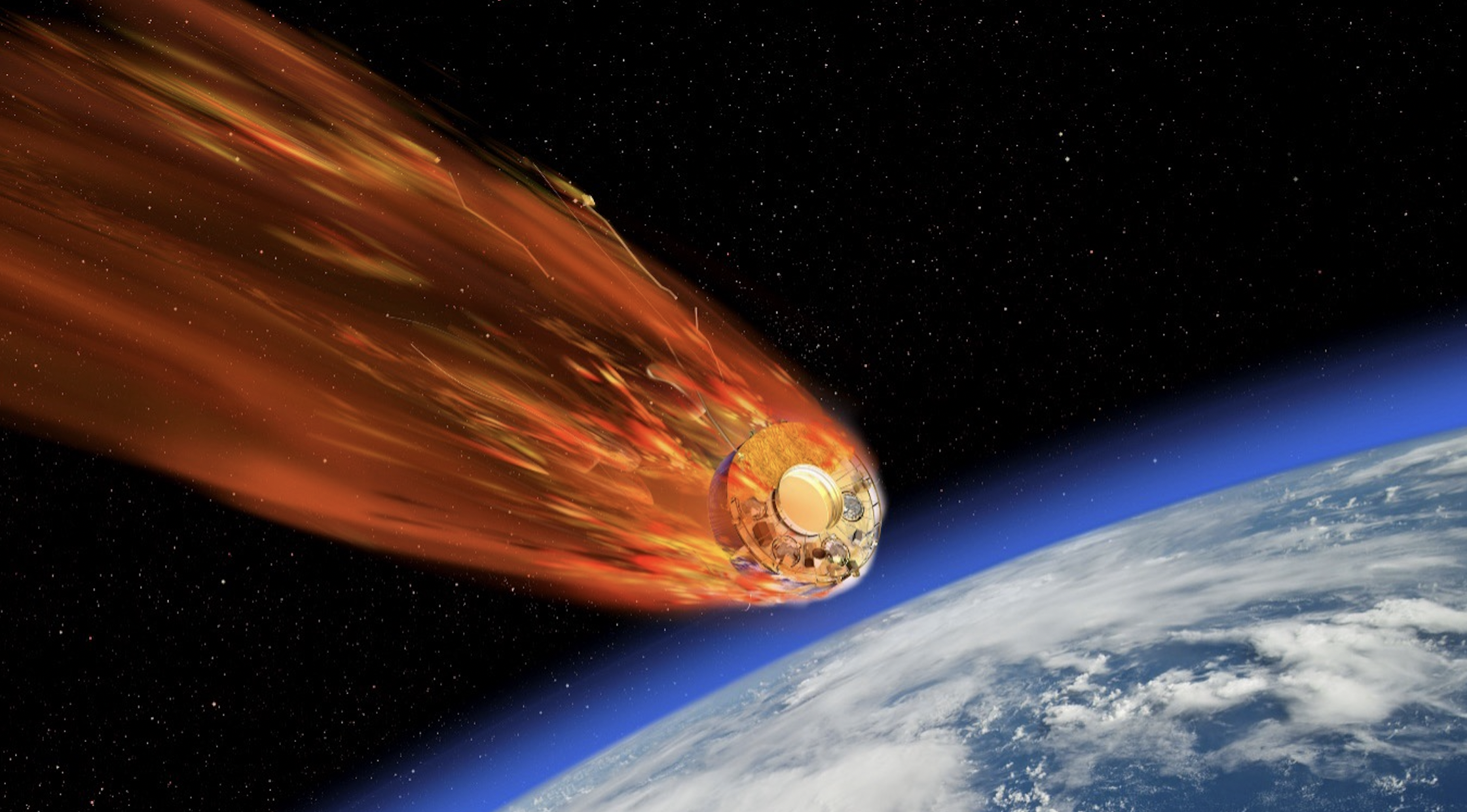

Megaconstellation operators want to replace their satellites every five years with newer, more powerful ones. To prevent the accumulation of space debris, they plan to dispose of old satellites by sending them into the atmosphere to burn up.

U.K. start-up Space Forge, however, proposes a different solution. Satellites should be designed to survive the fiery reentry so that they can be recovered on the ground, refurbished and launched again.

Space Forge is an in-orbit manufacturing startup developing large foldable heat shields that can survive the atmospheric fly-through intact, protecting the precious made-in-space materials aboard the spacecraft during the return to Earth.

If the idea takes off, the technology could completely change how things are done in space.

"We think that moving towards the strategy of returning satellites intact, refurbishing them and relaunching them, could be part of the solution to the [satellite air pollution] problem," Andrew Bacon, Space Forge chief technology officer and co-founder said at a September 2024 workshop on Protecting Earth and Outer Space from the Disposal of Spacecraft and Debris held at the University of Southampton in the U.K.

"There's lots of economic reasons to do so. We just need to get over the technological hurdles," he added.

So far, only a handful of spacecraft have been designed to survive their fall from the sky — for example, human-rated spaceships, capsules with samples from asteroids and other celestial bodies and SpaceX's Cargo Dragon. Other spacecraft perish during the plunge to Earth, either disintegrating completely, or, in some cases, leaving behind charred remnants of metal, which (usually) crash down in remote areas where they cause no harm to humans and property.

Space debris recycling

Instead of recovering returned satellites from Earth's surface, some technologists think it would be better to recycle and reprocess spacecraft in orbit. Speaking at the Southampton workshop, Patrick Neumann, chief scientist and co-founder of Australian startup Neumann Space, introduced an idea of a novel electric propulsion system that could use aluminum from old satellites as fuel. The process is a little more complicated than just collecting space junk and feeding it into a thruster. It requires an orbiting foundry that processes the collected junk.

"The system can use anything solid and conductive as propellant, and this includes aluminum alloys," Neumann said in his presentation.

The propulsion system, Neumann explained, is based on cathodic arc technology that is commonly used for thin film depositions and coatings.

"It operates similarly to an electric welder," Neumann said. "An arc is struck between the cathode and the anode. It evaporates material from the cathode surface, ionizes it and accelerates it downrange. The plasma derived from the cathode is now the exhaust and pushes the spacecraft along."

Neumann Space is part of a consortium of companies working as part of a

Small Business Innovation Research Program project funded by NASA. The firms, including active debris removal pioneer Astroscale, Nanoracks and Cislunar Industries, want to launch a demonstration mission that would prove that the novel thrusters can run on fuel made directly in space from satellite junk.

Related: Kessler Syndrome and the space debris problem

Engineered reentries

Recoverable satellites and in-orbit debris recycling are both completely new technology concepts that are still years away from being implemented in a meaningful fashion. But there are ways to reduce the amount of dangerous satellite ash in Earth's atmosphere almost immediately, Minkwan Kim, associate professor in astronautics at the University of Southampton, told Space.com.

Scientists know that satellites burn up at altitudes between 37 miles and miles (60 to 80 kilometers). The arising chemical compounds remain in the atmosphere for decades, maybe centuries, gradually sinking to lower altitudes and causing harm along the way. But satellite operators can guide satellites to disintegrate at lower altitudes, at 10 to 20 miles (20 to 30 km), Kim said, and thus decrease the extent of the damage.

"At those altitudes, the metallic oxides would be present for a much shorter time," said Kim. "They would drop to the ground much faster, and their impact would not be significant."

The operators can also alter the angle at which satellites enter the atmosphere. That, in turn, changes the temperature the spacecraft is exposed to as it hurtles through the thickening air.

"We found scientifically that, when metal is burned, some of it forms metal particles and some forms metal oxide," said Kim. "We think that the metal particles are not as harmful to the environment as the metal oxides. By changing the temperature at which a satellite burns, we can make more of it turn into particles rather than oxides."

New materials

Scientists are also thinking about whether they could replace aluminum alloys, currently the go-to material in satellite and rocket manufacturing, with something more environmentally friendly.

This research, however, is in very early stages. Kim warns that new materials could present new challenges that are currently not understood.

"The problem is, once we introduce a new material, the new material might cause a similar thing," said Kim.