Boeing 757 Jet Loses Wheel Before Takeoff in Atlanta

In a recent incident, a Boeing 757 jet operated by Delta Airlines lost a wheel just moments before takeoff at Hartsfield-Jackson Atlanta International Airport. The incident was reported by both the Federal Aviation Administration (FAA) and Delta Airlines. Communication between the air traffic control tower and the aircraft revealed that one of the nose tires of the Boeing 757 had dislodged and rolled off the runway, coming to rest behind the aircraft.

Following the incident, authorities confirmed that one of the tires on the Boeing 757 had separated and rolled down an embankment. The plane was subsequently taken off the taxiway for further inspection. The incident adds to the mounting scrutiny surrounding Boeing, as it comes after a door plug blew off a Boeing Alaska Airlines flight earlier this month involving a Boeing 737 Max 9.

The CEO of Alaska Airlines spoke about the ongoing issues with the Boeing Max planes, which have been temporarily grounded as a result of the door plug incident. The CEO mentioned the discovery of loose bolts on multiple Max aircraft during inspections. These findings are expected to be rectified through the inspection process.

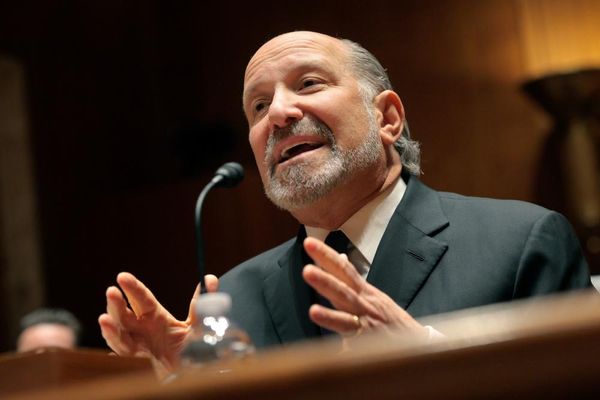

Concerns are growing regarding the quality control procedures at Boeing in relation to the construction of the 737 Max 9 aircraft. The head of the FAA stated that the investigation is now primarily focused on quality control. The FAA had previously grounded the Max 9 in the United States while determining the appropriate inspection protocols for airlines. In a recent interview, the FAA Administrator highlighted that the design of the Max 9 door plug is sound, but its execution is crucial.

The bolts that secure the door plug in place play a critical role in maintaining its integrity. If these bolts are not properly installed, the door can shake loose from its retaining grooves, potentially leading to explosive force, as witnessed in the January 5th incident involving Alaska Airlines Flight 1282.

In response to these concerns, the FAA has stationed inspectors at the Boeing plant in Renton, Washington. Their objective is to scrutinize the production processes and identify potential areas of concern. The FAA has also gathered data from a quarter of the Max 9 aircraft in the US and is evaluating the measurements in order to issue ungrounding orders.

Public safety remains a top priority for the FAA. The agency has reiterated that the Max 9 aircraft will not be allowed back in the air until they are confident that the underlying issues have been effectively addressed. As part of their efforts to ensure safety, Boeing has announced a safety stand down, commencing tomorrow. During this one-day pause, workers will engage in extensive sessions and group discussions focused on quality improvement.

The decision by Boeing to halt production across the entire factory highlights the significance of the issue at hand. This proactive approach to address quality concerns mirrors the practices typically employed by the military after a plane crash. It remains to be seen whether Boeing will continue implementing these safety stand downs in the future.

The aviation industry will be closely monitoring the outcome of investigations and the subsequent measures taken by Boeing and the FAA to rectify the identified issues. The goal is to restore confidence in the safety and reliability of the Boeing 737 Max 9 and ensure the uninterrupted operation of these aircraft in the future.