KISSIMMEE, Florida – Staring down an empty dead-end street, I press the gas to the floor. The Tesla engine makes an otherworldly hum, even more uncanny coming out of an antique British farm vehicle.

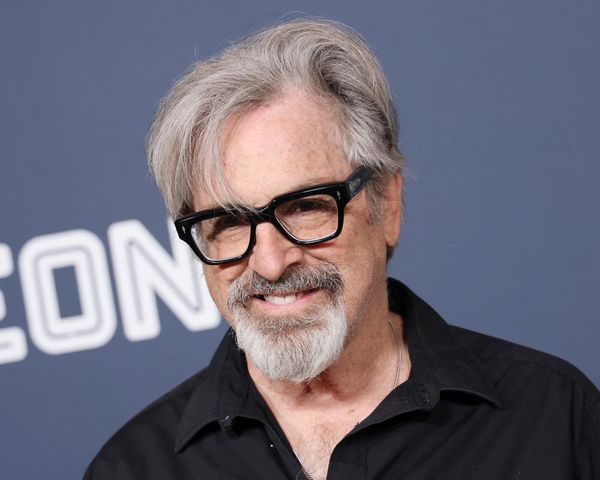

“It sounds like the future,” said Scott Wallace, co-founder of ECD Automotive Design.

Founded in 2013, ECD creates high-end custom builds of classic British Jaguars and Land Rovers. In November, the company opened a 100,000-square-foot production facility off Poinciana Boulevard and invited the Orlando Sentinel to take a tour.

The company began over beers when co-founder Tom Humble came to a barbecue at Wallace’s Davenport house in a Land Rover Defender. Both British immigrants to the country, Wallace, Humble and his wife, Emily, began talking about their love for the Defender series. Humble had grown up near the factory where they were built.

Based on an English World War II service vehicle, the rugged farm truck is seen in movies from 1953′s “Mogambo” to “The Da Vinci Code” in 2006.

“It’s funny, because the American association with it is safari,” Wallace said. “But’s it’s really like the (Ford) F-150 of the UK.”

Wallace said he and the other founders came from outside the automotive world when they started, himself a venture capitalist.

“We were going to work on a product that excited us,” Wallace said. “Somehow, we convinced ourselves there was a market for it.”

With cars starting at $219,000, that market is elite but apparently strong enough that ECD completes about 100 unique builds every year.

The process starts with the design. As the anointed reporter, I first talked with sales and design lead John Price for a video call.

I chose one of the newer rebuilds ECD is offering, a vintage Jaguar E-Type, a fantasy from my days as a pretentious high school student.

ECD offers customizations of nearly every aspect of the vehicle, from paint, lights and finishes to seating and fabrics to custom electronic dash displays, gauges and even a choice of one of seven engines.

Had I been a client, I would have been sent a welcome box with fabric and paint samples to help me design my build.

I selected the electric drivetrain from Tesla. That decision alone adds nearly $30,000 to the price.

I wasn’t able to get everything I wanted, such as a shifter with a chrome skull knob. The electric engines use a dial instead of a stick. But I was able to score vegan leather in an alligator pattern for the seats and hardwood floors. They even put in the classic car phone I used to dream of.

At the plant, I was shown a 3-D mock-up of what my forest green E-Type would look like. Th virtual presentation allowed me to see the paint with different levels of gloss and alter the color gradient for the interior.

All told, my imaginary vehicle came to about $320,000, according to Price.

From the time a vehicle is ordered, the first step is sourcing the vehicle. This is particularly difficult for the Defender, which has not been sold in the U.S. since 1997. JLR re-released a new Defender as a luxury SUV in 2020, but “that’s not for our clients,” Wallace said.

To import a classic Defender, the vehicle must be over 25 years old. ECD has a team dedicated to hunting them down in Britain and Europe.

“They’re mostly just sitting at people’s homes,” Wallace said, and ones that have been used for farm work, as the Defender commonly was, are not in great condition.

When the vehicle arrives at the plant, it is stripped down completely to the chassis which is polished and re-galvanized. The rest of the vehicle is also worked over, and any unusable parts are replaced.

From there, the car moves into the main production house of the facility lovingly called the “Rover Dome.” Cars are put into one of two lines, each with six bays or stations. The car will spend four days in each bay, with each team working off an electronic checklist of everything that has to happen.

“We run it like a sports team,” Wallace said, dividing his staff into offense, defense, special teams and locker room.

The staff of about 70 is given broad authority to complete their tasks in any way they think will lead to the best result. For example, when someone on the paint team decided they didn’t like the brand of clear coat they were using, they started buying another brand without consulting management.

“The person who made that decision was a painter,” Wallace said. “He wanted it to be better. That wasn’t us.”

Each vehicle takes roughly 110 days from sourcing to completion, or roughly 2,200 hours of work. A car will sit for four days in its final bay so that each employee can look it over and point out anything they think needs to be fixed or touched up.

Finally, the car is ready to drive. Wallace said each vehicle receives 850-1,000 test drive miles before it goes to the client.

As the car I designed was little more than a digital fantasy, I had to drive what they had on the lot. My first test was of a Defender 110 with the Tesla engine.

The car had more pickup than I expected, and steering and braking were much more of an active experience than my usual Toyota Corrolla.

“It’s meant to be a floaty drive,” Wallace said, describing the Defender’s difficult steering. “We don’t want to change it from what it is.”

I also got to try a Defender 90 (a little smaller) with a Corvette’s LS3 engine under the hood. The steering and brakes were the same, but the rumble of the engine was a powerful experience I could feel in the seat.

While clients need a pretty penny to take one of these vehicles home, Wallace said they aren’t just for buyers. On Instagram, ECD has more than 69,000 followers, and hundreds of viewers tune into ECD Live on YouTube where they livestream the building of each vehicle.

Wallace said the company has even had tourists come for tours of the facility.

“If we were known as a pompous company, I’d really hate that,” he said.