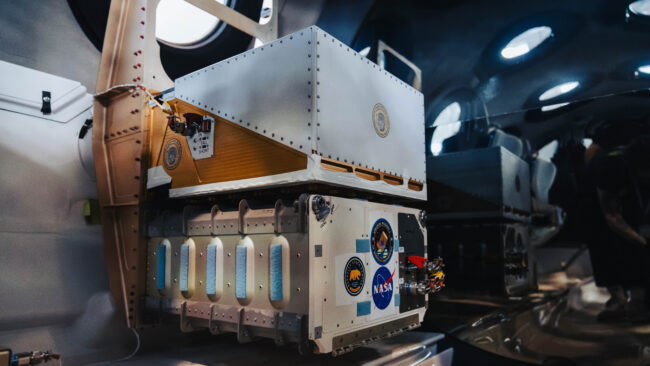

Scientists with the University of California, Berkeley, have carried out successful tests of a next-gen microgravity 3D printer called SpaceCAL. The tests were carried out as part of the Virgin Galactic 07 mission, a crewed suborbital spaceflight that launched on Monday (June 8).

During its 140-second trial run, SpaceCAL 3D printed four items from a liquid plastic called PEGDA. These included space shuttle models and small tugboats called "Benchys," conventionally used as benchmarks (hence the name) to evaluate a printer's quality and performance.

"SpaceCAL performed well under microgravity conditions in past tests aboard parabolic flights, but it still had something to prove, said Taylor Waddell, a Ph.D. student and contributing researcher on the project, in a statement. "This latest mission, funded through NASA’s Flight Opportunities program and with support from Berkeley Engineering and the Berkeley Space Center, allowed us to validate the readiness of this 3D printing technology for space travel."

3D-printing technologies have surged in the last decade, changing manufacturing forever. Early models were primarily printed using 3D pixels called voxels, which are built up very meticulously — point by point; layer by layer — into a 3D structure. In the last five years, scientists have advanced the capabilities of this tech ever further, manufacturing more sophisticated and creative 3D parts made from materials ranging from metals all the way to biomaterials.

Related: Future moon astronauts may 3D-print their supplies using lunar minerals

SpaceCAL's predecessor on the ground, simply called "computed axial lithography" (which is where the CAL comes from), was developed by Hayden Taylor and his group at Berkeley in 2017. The scientists aimed to address a lack of 3D printing techniques capable of printing complex, custom-defined 3D geometries in a single print step.

Instead of building structures from the bottom up, CAL used light to trigger the chemical hardening of projected patterns in a photosensitive resin, "such that in a single unit operation with a single development step, a 3D part of arbitrary user-defined geometry is generated."

The curing of the design occurs as a result of a polymerization reaction, in which chemical building blocks found in the resin connect into a chain, or polymer, under light, which results in high-resolution, complex 3D structures precisely and rapidly forming.

CAL (and SpaceCAL) can create intricate parts in as little as 20 seconds — a remarkable improvement over printers that typically require hours to create similar objects. The team has also demonstrated the system's versatility, successfully printing with over 60 different materials, such as silicones, glass composites and different biomaterials, according to the press release.

Its ability to operate effectively in microgravity environments, where many other 3D printers face challenges, makes both CAL and SpaceCAL particularly promising for applications in space exploration. In fact, low-gravity environments may give 3D printing an edge as the absence of gravity minimizes issues related to material flow and settling, enhances some material properties, and can improve freedom of design.

"With CAL, we were able to demonstrate — first on those [first] zero-G missions and now on this spaceflight — that we can print parts in microgravity that are not possible on Earth,” said Waddell.

These developments are exciting as 3D printing will likely be an integral part of upcoming space missions. NASA and the European Space Agency have already begun pushing ahead with plans for 3D printing on the moon and in the International Space Station.

"You can reduce that upmass, make these missions go faster and reduce risk by bringing manufacturing technologies with you," said Waddell.

This could provide astronauts with a means of independently producing building materials, tools, medical equipment and spare parts on site. "If your spacecraft is breaking down, you can print O-rings or mechanical mounts or even tools," Waddell said.

With advancements in 3D bioprinting, this could also mean replacement organs or tissue. "CAL is also capable of repairing the crew," Waddell added. "We can print dental replacements, skin grafts or lenses, or things personalized in emergency medicine for astronauts, which is very important in these missions, too."

But 3D printed objects in space could still make their way to our planet to serve humans living on the ground. "The long, long-term goal is to print organs up in space with CAL, then bring them back down to Earth," Waddell said.

"These experiments are really focused on pushing technology for the betterment of everyone," he continued. "Even though it's for space, there are always tons of ways it can benefit people back here on Earth."