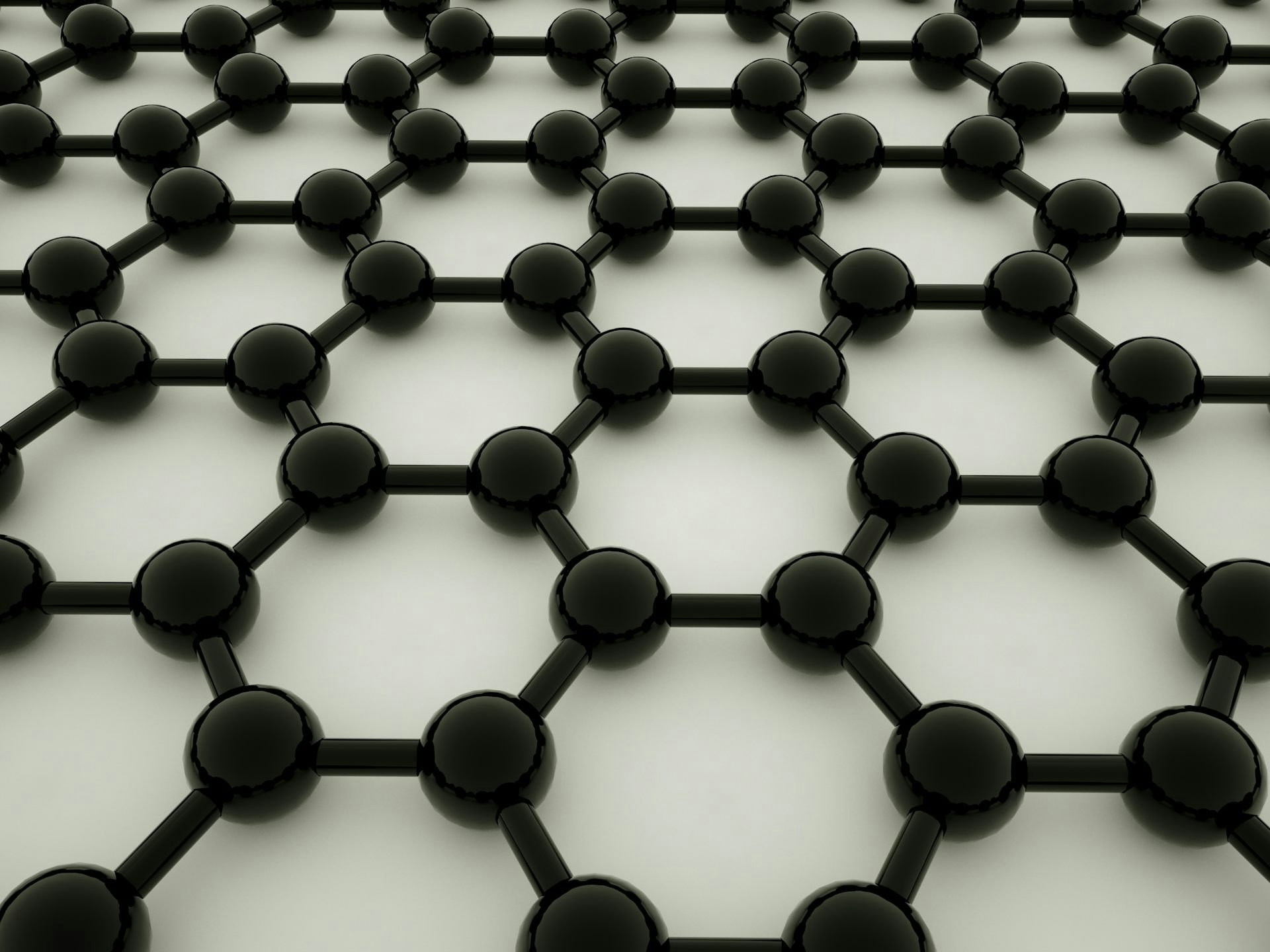

Twenty years ago this October, two physicists at the University of Manchester, Andre Geim and Konstantin Novoselov, published a groundbreaking paper on the “electric field effect in atomically thin carbon films”. Their work described the extraordinary electronic properties of graphene, a crystalline form of carbon equivalent to a single layer of graphite, just one atom thick.

Around that time, I started my doctorate at the University of Surrey. Our team specializes in the electronic properties of carbon. Carbon nanotubes were the latest craze, which I was happily following. One day, my professor encouraged a group of us to travel to London to attend a talk by a well-known science communicator from the University of Manchester. This was Andre Geim.

We were not disappointed. He was inspiring for us fresh-faced PhD students, incorporating talk of wacky Friday afternoon experiments with levitating frogs before getting on to atomically thin carbon. All the same, we were skeptical about this carbon concept. We couldn’t quite believe that a material effectively obtained from pencil lead with sticky tape was really what it claimed to be. But we were wrong.

The work was quickly copied and reproduced by scientists across the globe. New methods for making this material were devised. Incredible claims about its properties made it sound like something out of a Stan Lee comic. Stronger than steel, highly flexible, super-slippery and impermeable to gases. It is a better electronic conductor than copper and a better thermal conductor than diamond. It is also practically invisible and displays a host of exotic quantum properties.

Graphene was hailed as a revolutionary material, promising ultra-fast electronics, supercomputers and super-strong materials. More fantastical claims have included space elevators, solar sails, artificial retinas, and even invisibility cloaks.

Just six years after their initial work, Geim and Novoselov were awarded the Nobel Prize in Physics, further fueling the enthusiasm around this wonder stuff. Since then, hundreds of thousands of academic papers have been published on graphene and related materials.

But not everyone is on board. Skim through the comments section of any popular article on the material, and you’ll quickly find the sceptics. We have endured decades of empty promises about the real-world impact of graphene, they complain. Where are the game-changing products to enrich our lives or save the world from climate change, they ask?

So, has graphene been a resounding success or a damp squib? As is so often the case, the reality is somewhere in between.

Graphene’s ups and downs

In terms of public perception, it’s fair to say that graphene has been held to an impossible standard. The popular media can certainly exaggerate science stories for clicks, but academics – including myself – are not immune from over-egging or speculating about their pet projects either. I’d argue this can even be useful, helping to drive new technologies forward. Equally, though, there can be a backlash when progress looks disappointing.

Having said that, disruptive technologies such as cars, television or plastic all required decades of development. Graphene is still a newcomer in the grand scheme of things, so it’s far too early to reach any conclusions about its impact.

What has quietly occurred is a steady integration of graphene into numerous practical applications. Much of this is thanks to the Graphene Flagship, a major European research initiative coordinated by Chalmers University of Technology in Sweden. This aims to bring graphene and related materials from academic research to real-world commercial applications, and more than 90 products have been developed over the past decade as a result.

These include blended plastics for high-performance sports equipment, more durable racing tyres for bicycles, motorcycle helmets that better distribute impact forces, thermally conductive coatings for motorcycle components, and lubricants for reducing friction and wear between mechanical parts.

Graphene is finding its way into batteries and supercapacitors, enabling faster charging times and longer life spans. Conductive graphene inks are now used to manufacture sensors, wireless tracking tags, heating elements, and electromagnetic shielding for protecting sensitive electronics. Graphene is even used in headphones to improve the sound quality and as a more efficient means of transmitting heat in air-conditioning units.

Graphene oxide products are used for desalination, wastewater treatment , and purification of drinking water. Meanwhile, a range of graphene materials can be bought off the shelf for use in countless other products, and major corporations, including SpaceX, Tesla, Panasonic, Samsung, Sony and Apple, are all rumored or known to be using them to develop new products.

From promise to practicality

The impact of graphene on materials science is undeniable. The impact on consumer products is tangible but not as visible. Once a material is embedded in a working product, there is little need to keep mentioning it, and proprietary concerns can make companies reluctant to get into details in any case. Consumers can, therefore, be blissfully unaware that their car, mobile phone, or golf club contains graphene and most probably don’t care as long as it works.

As production methods improve and costs decrease, we can expect graphene to become ever more widely adopted. Economies of scale will make it more accessible, and the range of applications is likely to continue to expand.

Personally, after two decades, I still get excited when I try it out for something new in the lab. While I may be guilty of having contributed to the initial hype, I remain optimistic about graphene’s potential. I’m still waiting for my ride on a space elevator, but in the meantime, I’ll take comfort in the fact that graphene is already helping to shape a better future – quietly and steadily.

This article was originally published on The Conversation by Stephen Lyth at the University of Strathclyde. Read the original article here.